Lightweight power battery pack

A power battery pack, lightweight technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low energy density and low integration of power battery packs, and achieve energy density improvement, weight reduction, and reduction of occupation. the effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

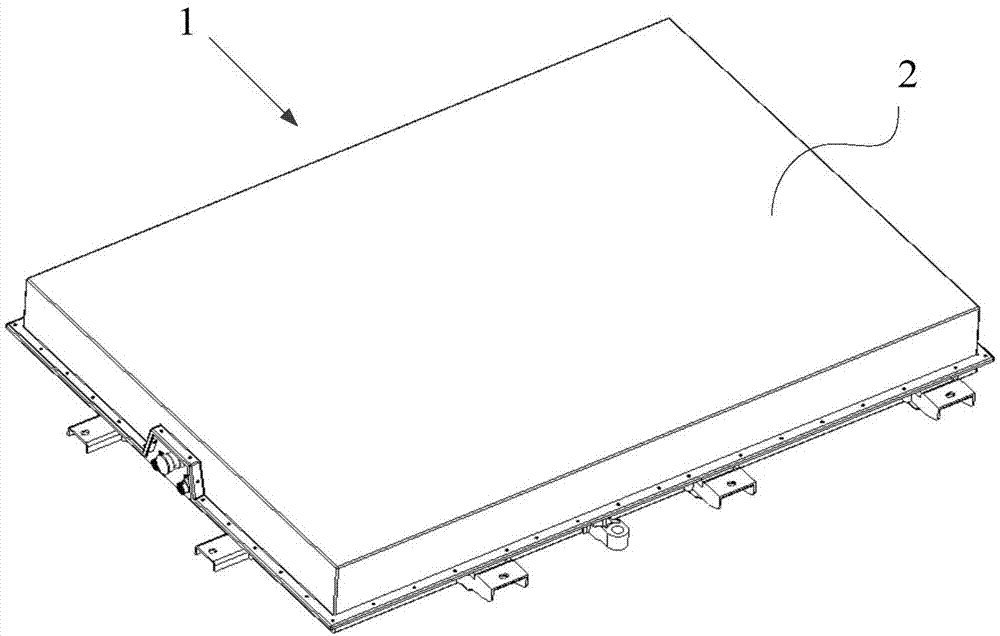

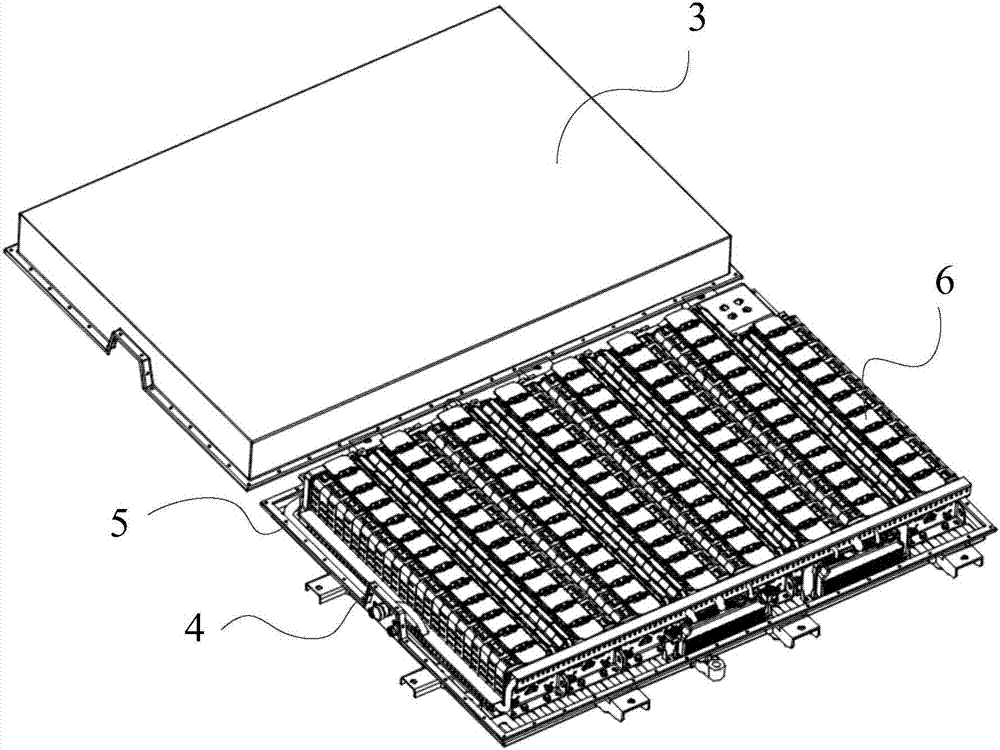

[0026] A lightweight power battery pack provided by the present invention is characterized in that:

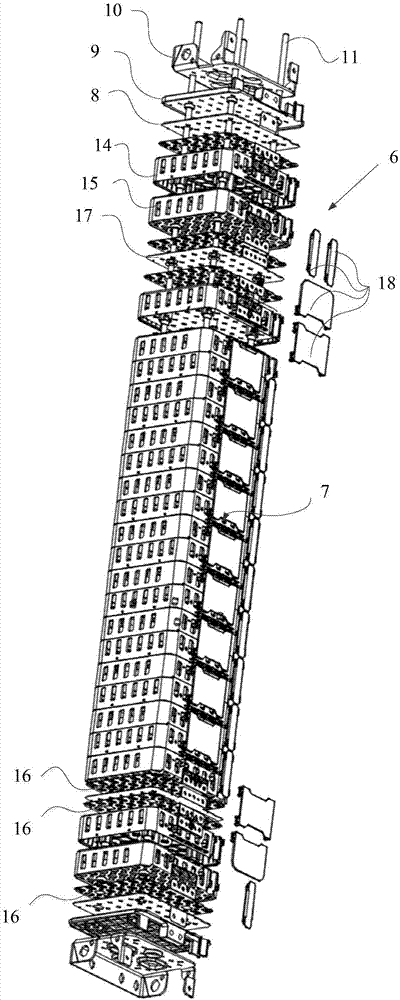

[0027] Including the box and eight battery modules located in the box, these eight battery modules include seven 12S battery modules and one 10S battery module, a single 12S battery module is composed of 12 battery modules stacked, A single 10S battery module is stacked by 10 battery modules; these battery modules are connected in series and neatly arranged in the box;

[0028] The box body includes a matching sheet molding plastic upper cover plate and a cast aluminum lower box body;

[0029] Each battery module includes a battery stack formed by stacking several battery modules and copper sheets vertically, copper bars arranged at both ends of the battery stack, insulating plates, support plates, and several screws; the copper sheets are arranged on every two adjacent between battery modules;

[0030] The copper bar is arranged on the outside of the battery stack, the insu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com