Processing technology and processing equipment of lithium battery isolation film

A processing technology and separation film technology, which is applied in the field of lithium battery separation film processing technology and processing equipment, can solve problems such as unwinding or bursting ribs, uneven film surface, and uneven winding of the separation film, so as to increase the yield Roll tension, flat and smooth film surface, and prevent uneven winding end faces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

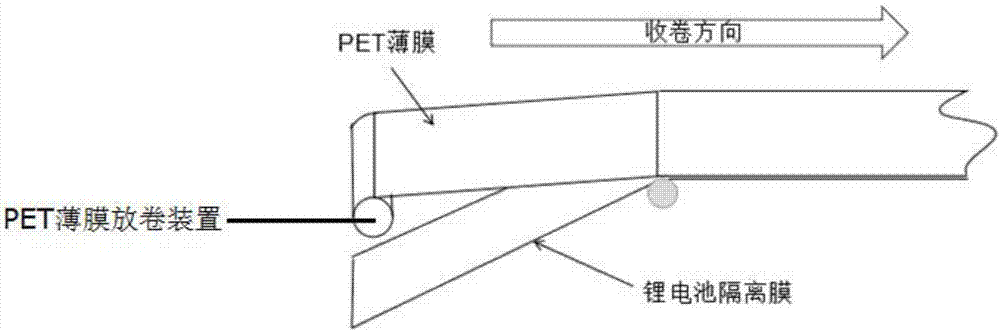

[0028] The processing technology of the lithium battery separator of the present invention includes: using the lithium battery separator as a base film, and adding a layer of PET on the outer surface or inner surface of the lithium battery separator when the lithium battery separator is coated and wound The film is used as a backing, and the PET film backing and the lithium battery separator are wound together, and then slitted, and the film surface of the PET film used as the backing is smooth and free of foreign matter. The lithium battery separator is a PP or PE film that plays the role of separating the positive and negative electrodes in the lithium battery. Besides PET, the material of the film backing can be selected from other similar or suitable materials in other embodiments.

[0029] See figure 1 , a schematic diagram of the processing technology and processing equipment of the present embodiment, figure 1 In the middle, the PET film backing and unwinding device i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com