Full-automatic turf harvester

A harvester, fully automatic technology, applied in the direction of lawn treatment machinery, agricultural machinery and implements, applications, etc., can solve the problems of single drafting function, laborious and time-consuming operation, low work efficiency, etc., to achieve suitable promotion, solve time-consuming and labor-intensive, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

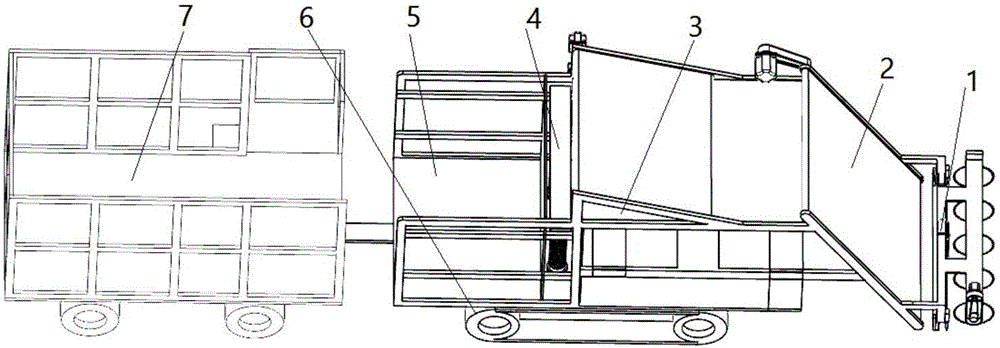

[0031] combine Figure 1-6 , a fully automatic turf harvester, comprising a cutting mechanism 1 arranged close to the ground for mowing grass, a transmission mechanism 2 connected to the cutting mechanism, a rolling mechanism 3, a stacking mechanism 4 and a stacking mechanism arranged in sequence along the turf conveying direction Zone 5 and the power mechanism for driving the harvester;

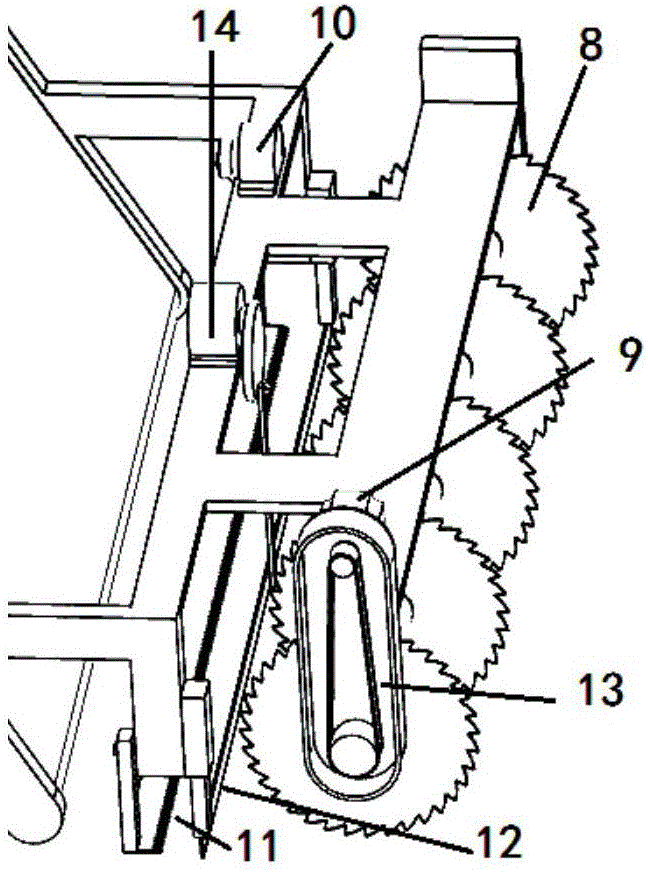

[0032] Further, the cutting mechanism 1 includes an equidistant cutting device, a vertical cutting device and a parallel cutting device arranged in reverse order along the harvester's advancing direction, through these three structures, the equidistant cutting of the turf will be realized and the turf will be cut from the surface. Down.

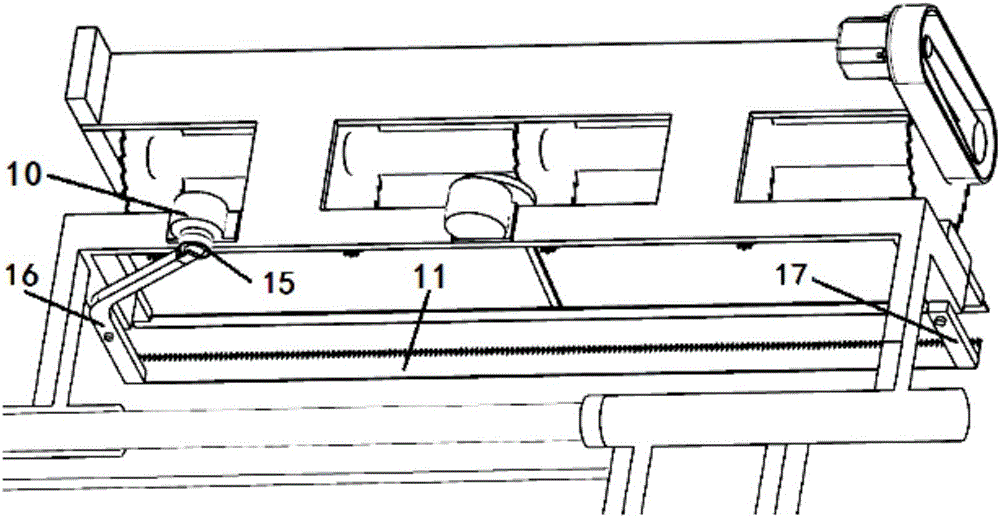

[0033] Specifically, such as figure 2 As shown, the bottom of the harvester is provided with a rotating shaft, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com