Embedded differential double-helix type green feed straw crushing and conveying device

A straw crushing and conveying device technology, which is applied in the fields of feed, food science, cutting equipment, etc., can solve the problems of green feed straw blockage, single equipment function, increased production cost and overall machine volume, and achieve the goal of reducing adhesion and blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

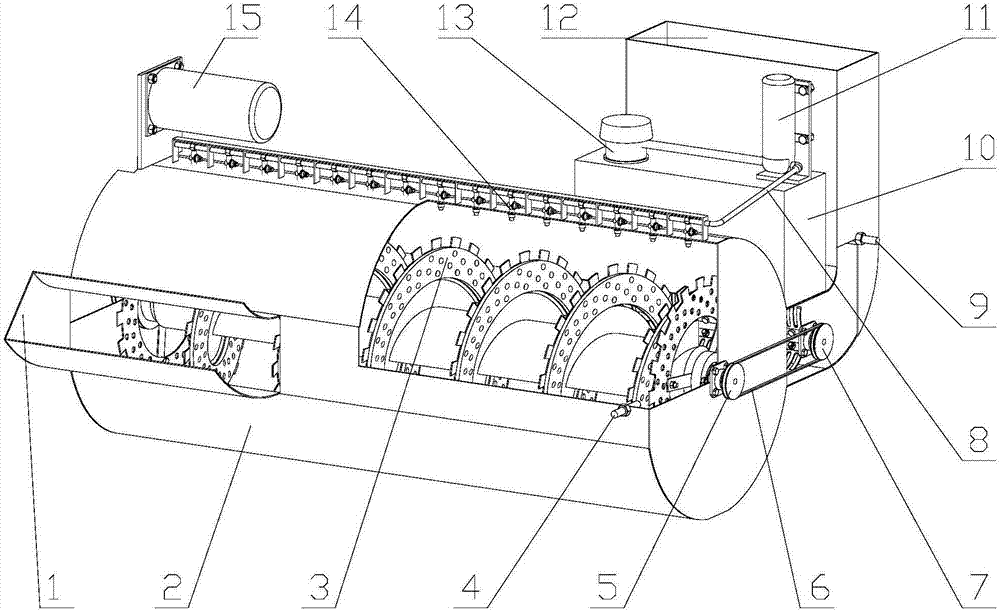

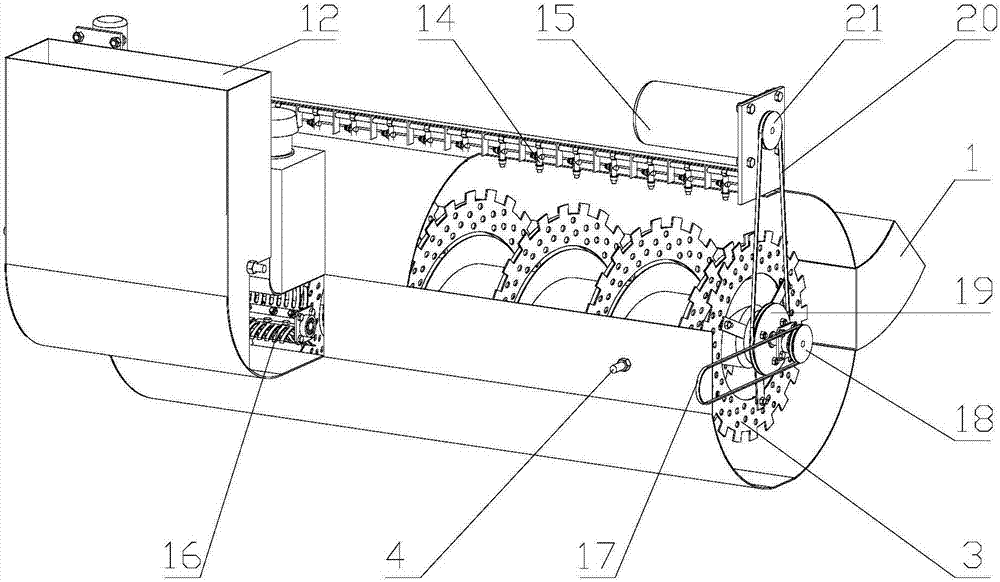

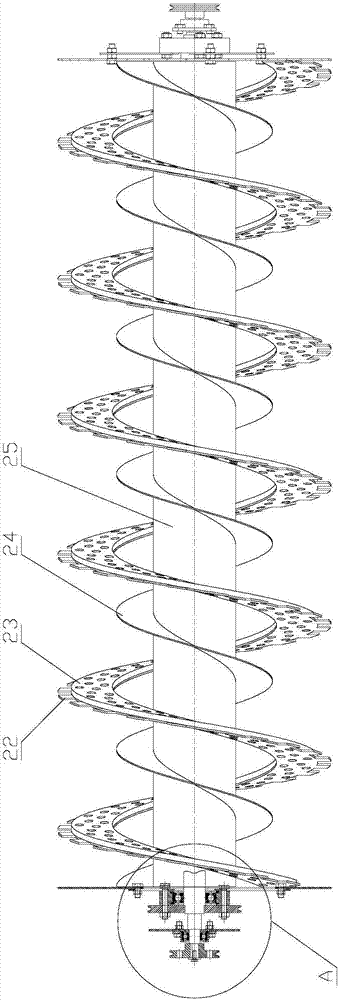

[0019] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention includes a frame 2, auger mechanism 3, spraying mechanism 8 and a throwing mechanism 16. The auger mechanism 3 is fixed at the front of the frame 2, and the spray mechanism 8 is fixed above the rear of the frame 2. , The throwing mechanism 16 is fixed below the rear of the frame 2; the frame 2 includes a feed inlet 1, a temperature sensor 4, a first pulley 5, a first belt 6, a second pulley 7, a humidity sensor 9, and an outlet The feed port 12, the hydraulic motor 15, the third belt 20 and the fifth pulley 21, the feed inlet 1 is fixed on the right side of the front of the frame 2, and the temperature sensor 4 is fixed on both ends of the middle of the frame 2. The first pulley 5 is fixed at the middle left end of the frame 2, the second pulley 7 is fixed at the rear left end of the frame 2, the first belt 6 is fixed on the radial outside of the first pulley 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com