Automatic curing system for preserved meat

An automatic, bacon technology, applied in food science and other directions, can solve the problems of slow cutting speed, affecting the appearance of products, uneven size of bacon, etc., and achieve the effect of reducing labor consumption, economic consumption and continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

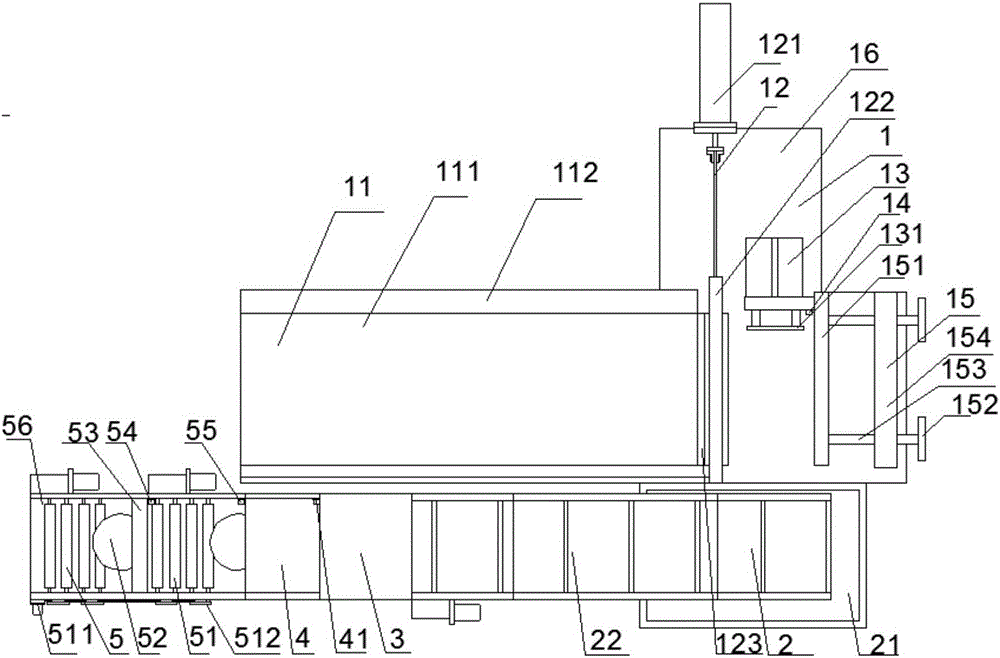

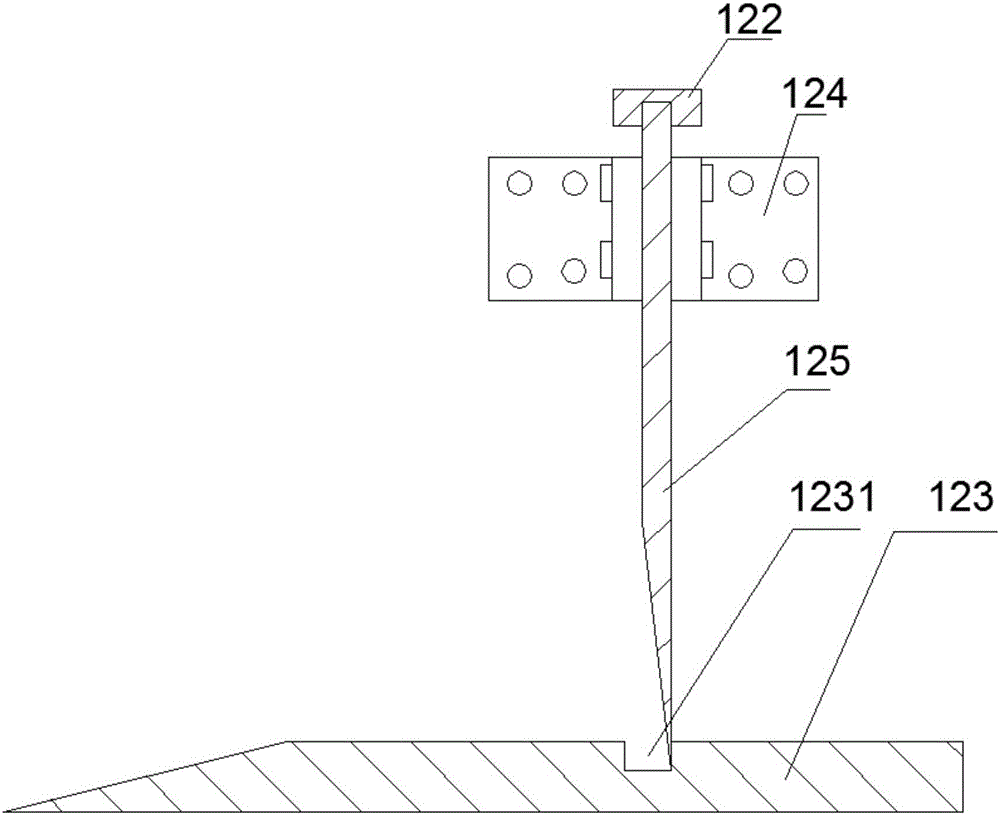

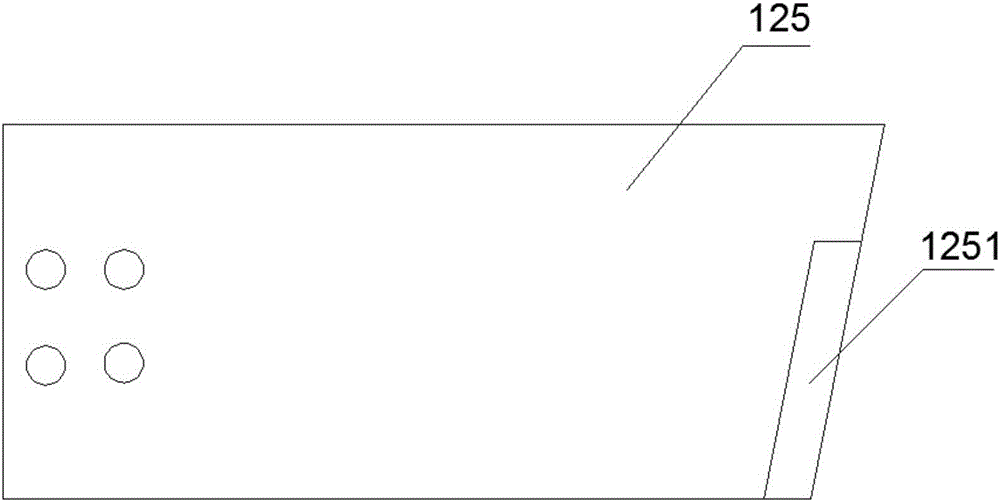

[0023] Such as figure 1 A kind of bacon automatic pickling system shown, comprises the meat cutting machine 1, cleaning device 2, weighing device 3, wine spraying room 4, pickling device 5 connected in sequence; The meat cutting machine 1 includes feeding device 11 , the meat cutting assembly 12, the blanking cylinder 13, the meat cutting sensor 14, the quantifier 15, the cleaning device 2 includes a cleaning tank 21, a feeding mesh belt 22, and the lower end of the feeding mesh belt 22 is arranged in the cleaning groove 21, The pickling device 5 includes a leveling brush 51, a lower hopper 52, a meat turning plate 53, and a feeding mesh belt 56, and the feeding device 11, the meat cutting assembly 12, the feeding cylinder 13, and the quantitative device 15 are sequentially installed on the bottom plate 16 on. The meat slices are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com