Automatic stabilizer bar end rubber part assembly device

An automatic assembly device and stabilizer bar technology, which is applied in vehicle parts, transportation and packaging, metal processing, etc., can solve problems such as asymmetry, out-of-axis stabilizing rubber parts, and tolerances, so as to achieve easy operation and reduce assembly tolerances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

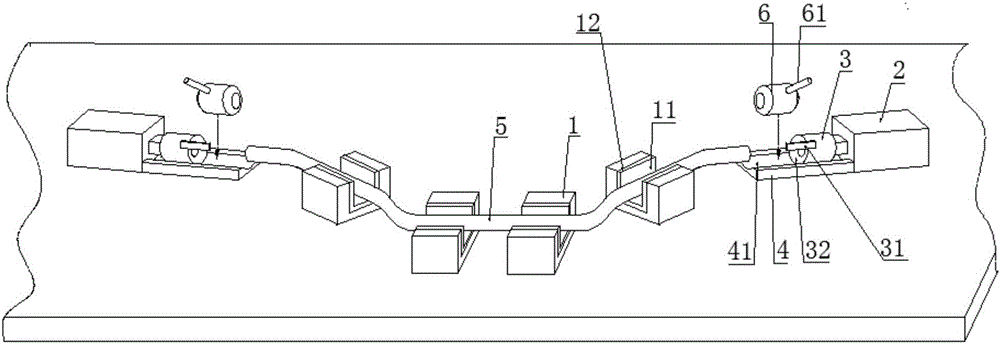

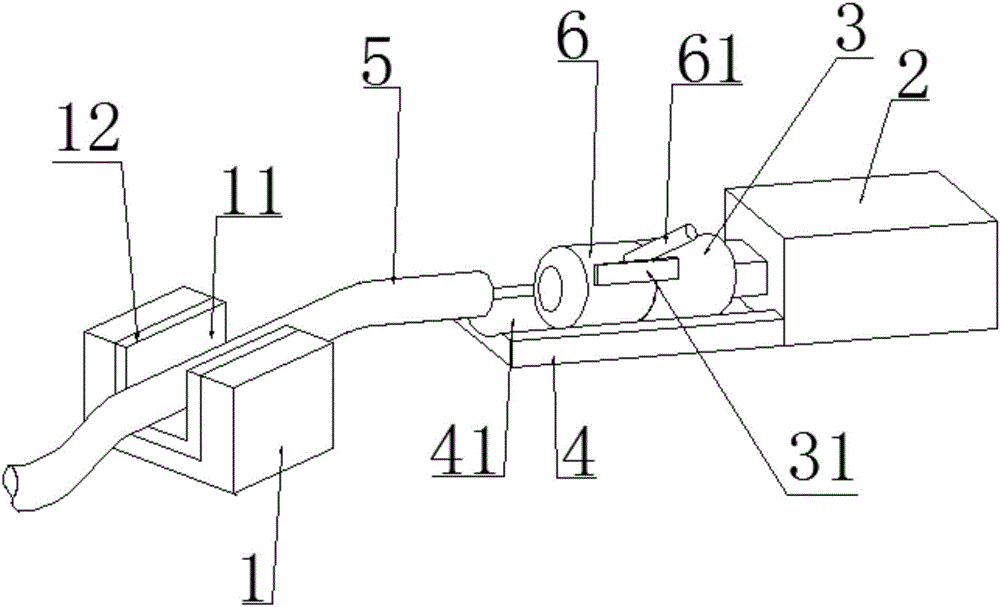

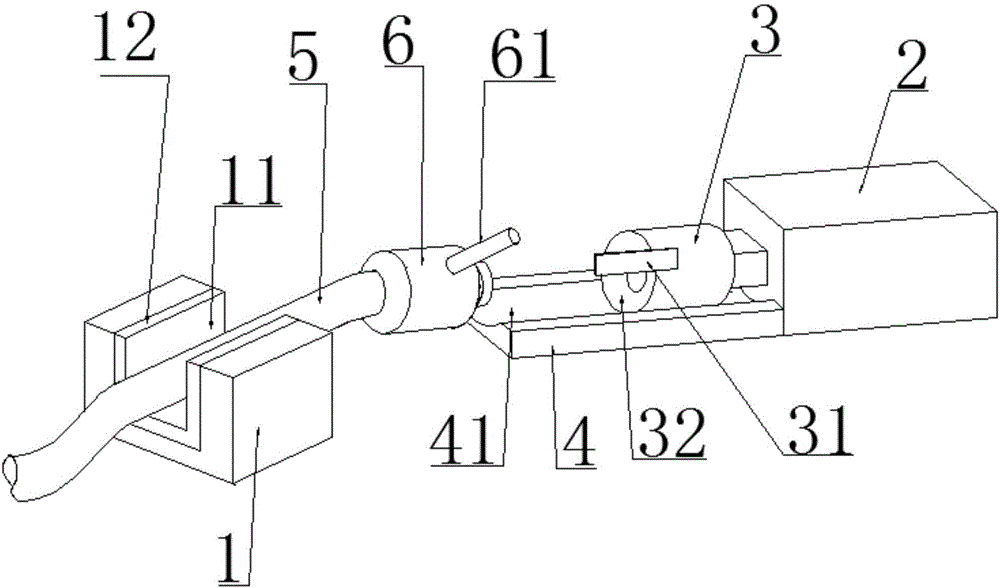

[0019] Such as figure 1 As shown, an automatic assembly device for rubber parts at the end of a stabilizer bar, including a workbench. A plurality of positioning parts 1 corresponding to the shape and direction of the stabilizer bar 5 and two cylinders 2 capable of driving the rubber part 6 are arranged symmetrically on the left and right sides of the workbench. The bottom of the positioning part 1 is fixed on the workbench. The upper end surface of the positioning member 1 is provided with a groove 11 along the direction of the stabilizing bar 5 which can accommodate the body of the stabilizing bar 5 . A soft pad 12 is provided in the groove 11 . The two cylinders 2 are arranged at both ends of the stabilizer bar 5 after positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com