A silica sand sampling device

A sampling device, silica sand technology, applied in the direction of sampling devices, etc., can solve problems such as inconvenience, achieve the effect of improving sampling efficiency, shortening sampling time, and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

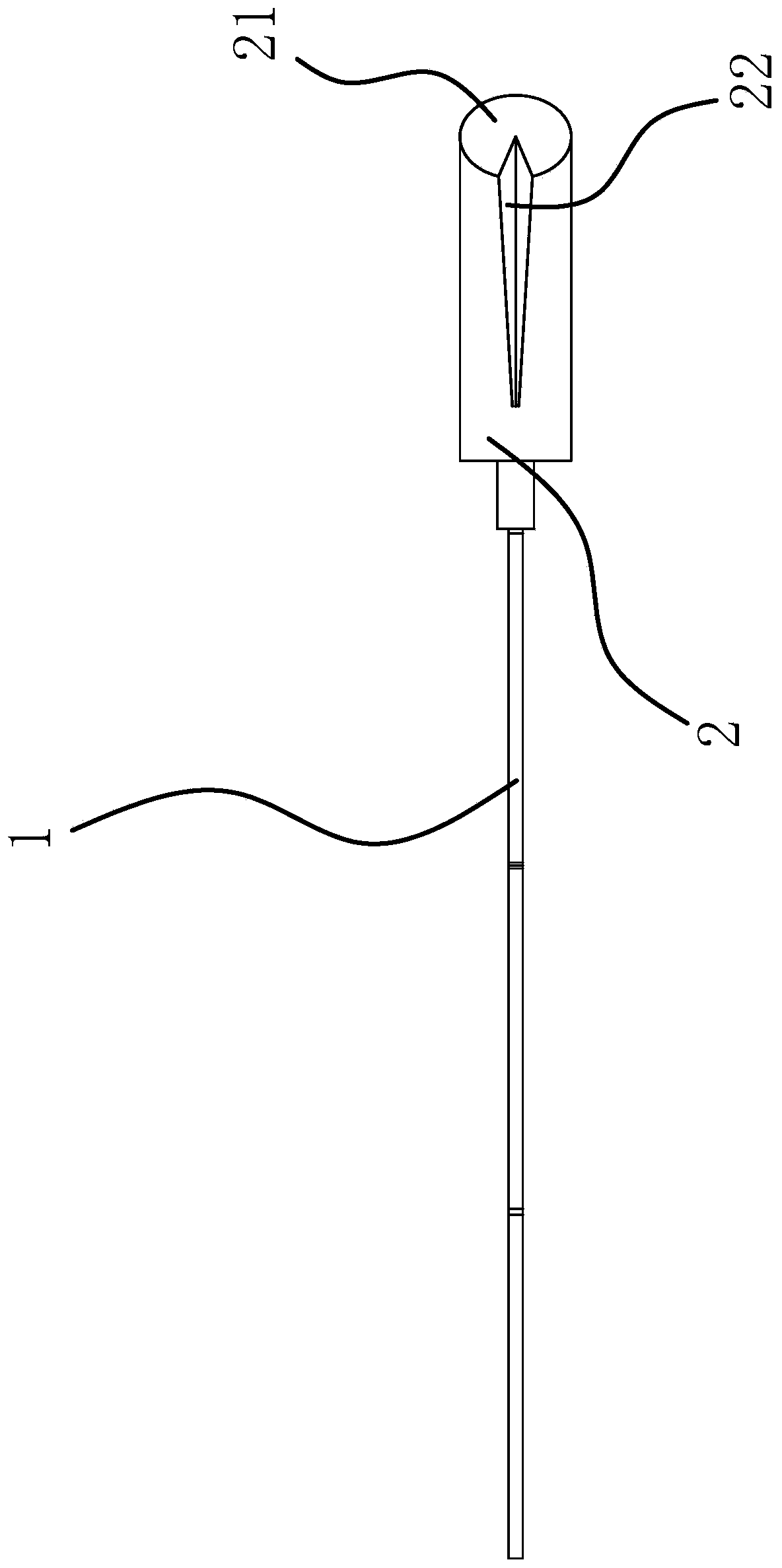

[0033] like figure 1 , figure 2 and Figure 8 As shown, the silica sand sampling device includes several rod-shaped shovel arms 1 and a cylindrical shovel head 2, the two ends of the shovel arm 1 are respectively provided with a threaded connection head 13 and a threaded connection hole 11, and one end of the shovel head 2 There is threaded connection hole 2 12, both threaded connection hole 1 and threaded connection hole 2 can cooperate with threaded connection head 13, the end face of the other end of shovel head 2 is a cutting surface 21, the distance between cutting surface 21 and the axis of shovel head 2 It is an included angle between 12°~70°. There is a sampling groove 22 on the shovel head 2. The sampling groove 22 runs through the outer peripheral surface of the shovel head 2 and the cutting surface 21. The sampling groove runs from the end close to the cutting surface 21 to the thread. One end of the connection hole two 12 continues to become smaller.

[0034] A...

Embodiment 2

[0037] The content of this embodiment is roughly the same as that of Embodiment 1, except that:

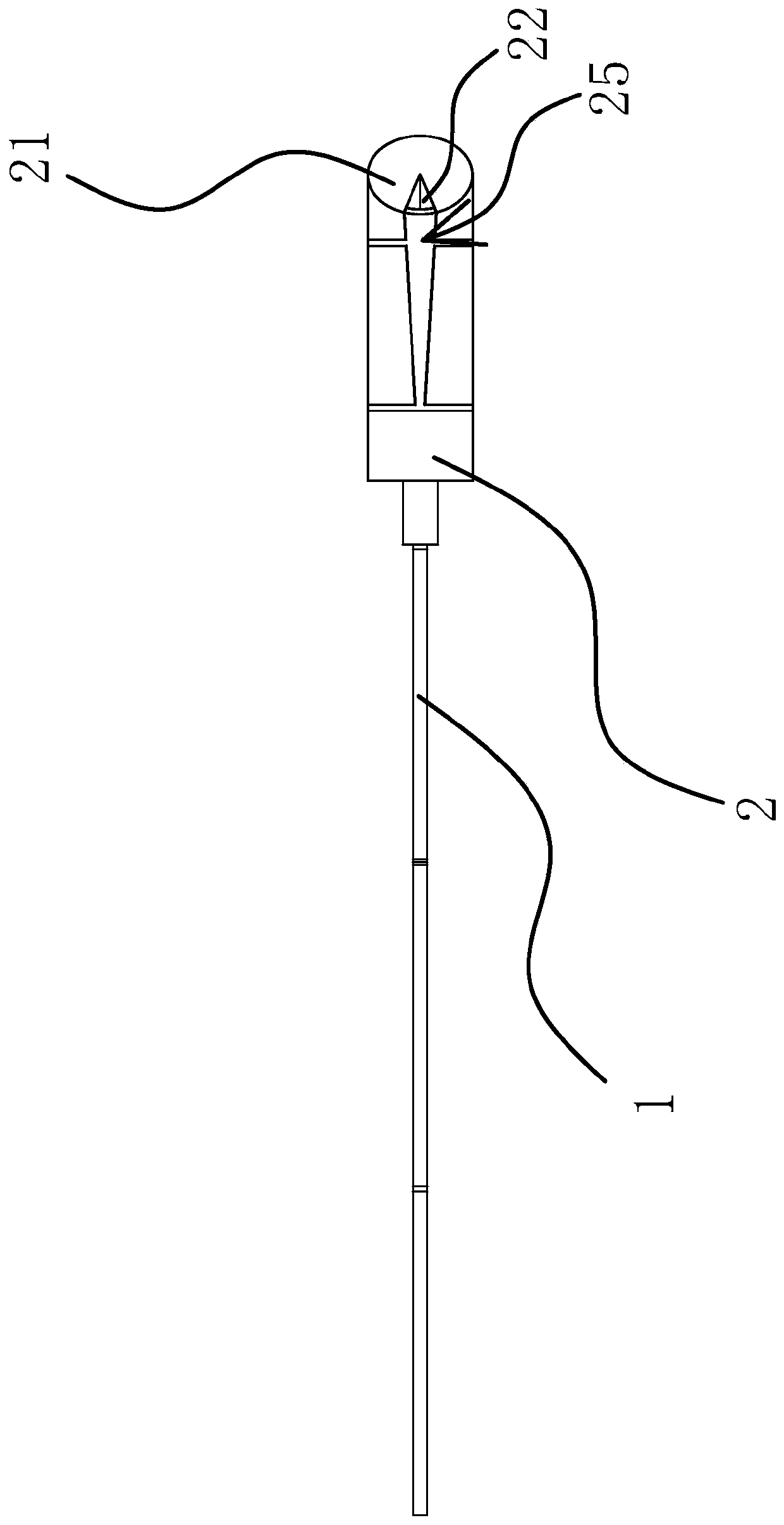

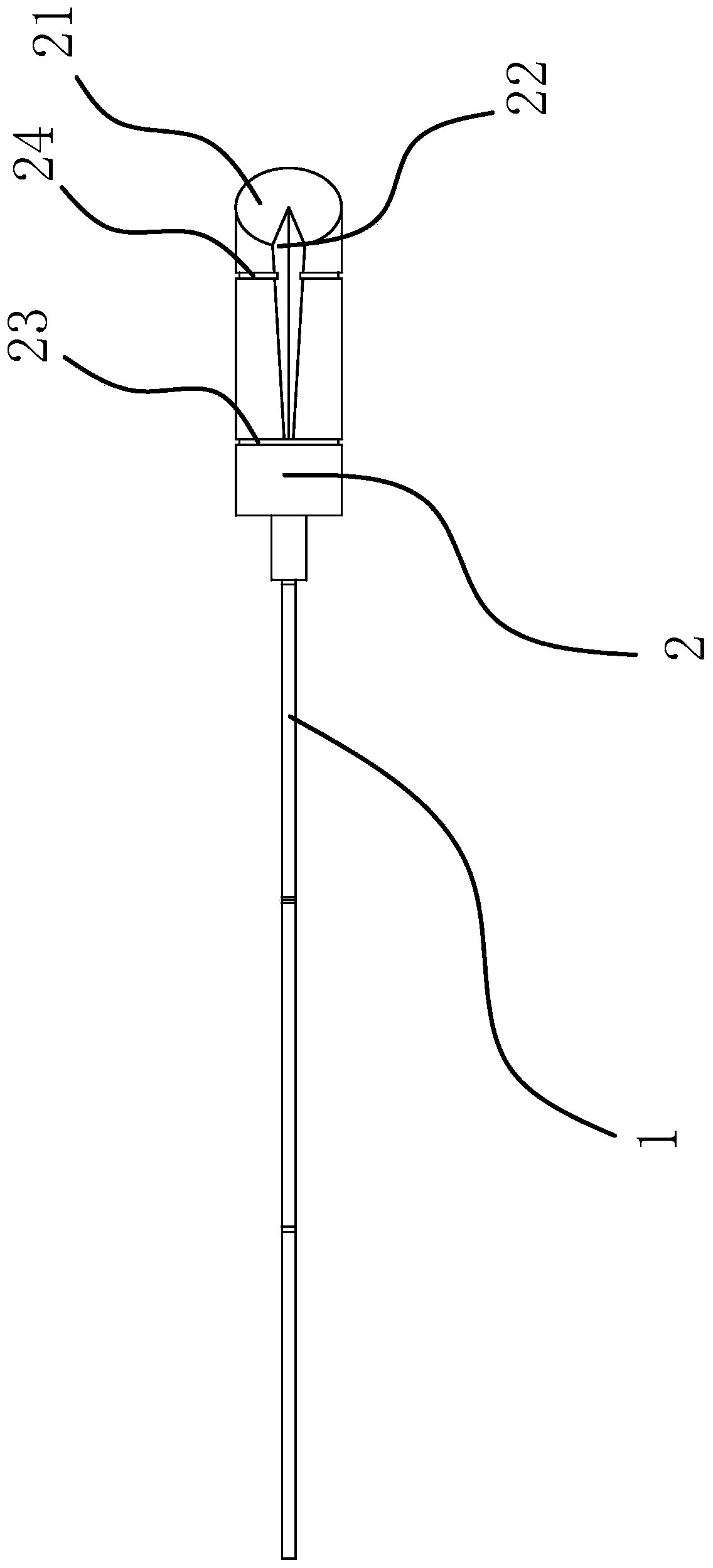

[0038] like image 3 and Figure 4 As shown, guide groove 1 23 and guide groove 2 24 are provided on the peripheral surface of shovel head 2, and the sampling device also includes a soft, elastic compression sleeve 25, which includes an annular leather sheath One 26, ring-shaped holster two 27 and bag piece 28, bag piece 28 is adapted to the breach of sampling groove 22 on the outer peripheral surface of shovel head 2, and bag piece 28 can sink in the sampling groove 22 and will sample groove 22 in the shovel The gap on the outer peripheral surface of the head 2 is blocked, and the bag piece 28, the first leather cover 26 and the second leather cover 27 are made into one, the first leather cover 26 is placed in the first guide groove 23, and the second leather cover 27 is placed in the second guide groove 24. The end surface of the wrapper 28 is in the same plane as the cutting ...

Embodiment 3

[0042] The content of this embodiment is roughly the same as that of Embodiment 1, except that:

[0043] like Figure 5 , Image 6 and Figure 7 As shown, several notches 31 are provided on the two inner walls of the sampling tank 22, and the notches 31 have pockets 32 that are sunken toward the cutting surface 21; The storage of raw material samples in the shovel head 2, and the notch 31 has a pocket 32, can guarantee the success of sampling.

[0044] The wrapper 28 has several pockets 33 that can bulge out of the sampling slot 22 , and the pockets 33 correspond to the notches 31 one by one. Utilize the elastic force of the bag portion 33 to tighten the silica sand sample in the sampling tank 22, a plurality of bag portions 33 and notches 31 form a plurality of compression structures in the sampling tank 22, and the silica sand samples in the notch 31 and the bag portion 33 can be retained , while also clamping the silica sand sample between adjacent notches 31 .

[0045...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com