electrical connector

A technology of electrical connectors and connectors, which is applied in the direction of connection, components of connection devices, circuits, etc., can solve the problem of lack of moving locking rings, etc., achieve overall axial volume reduction, axial length reduction, avoid The effect of the use of the entrance bevel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

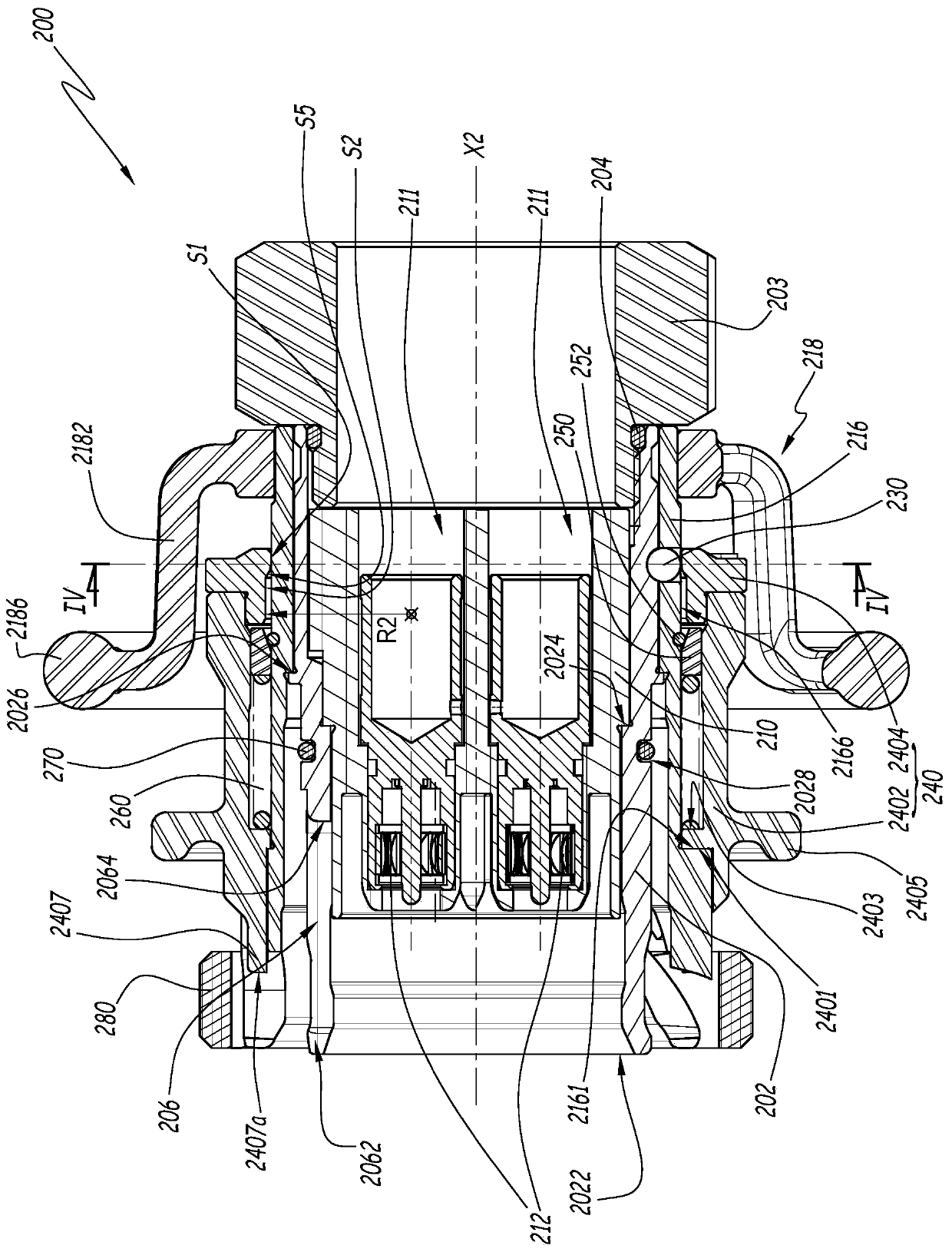

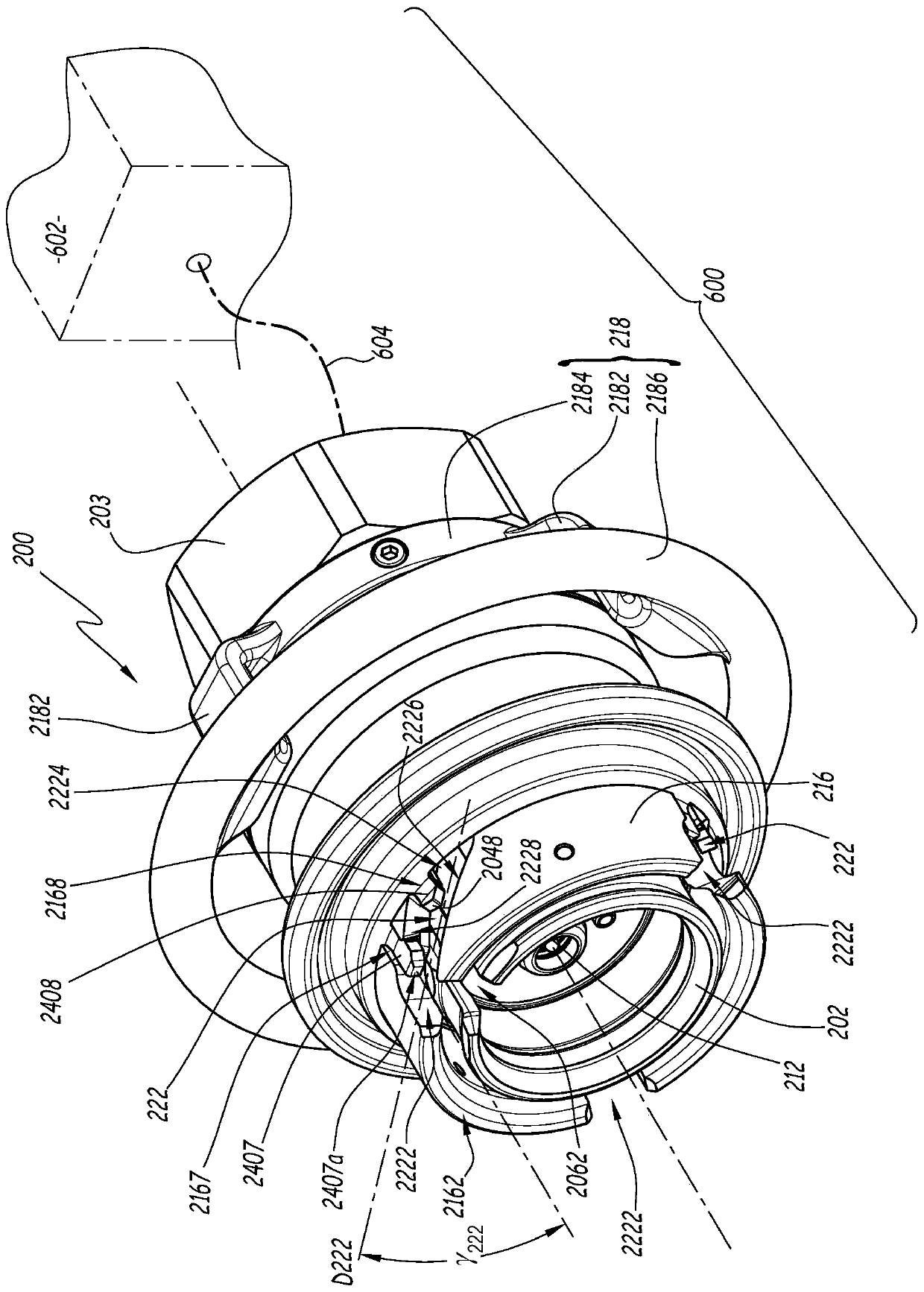

[0037]In the remainder of the description, the forward direction of the connector element is defined as the direction oriented in the fitting or coupling direction, ie towards the complementary connector element. In contrast, a rearward direction of a connector element is defined as being opposite to a complementary connector element.

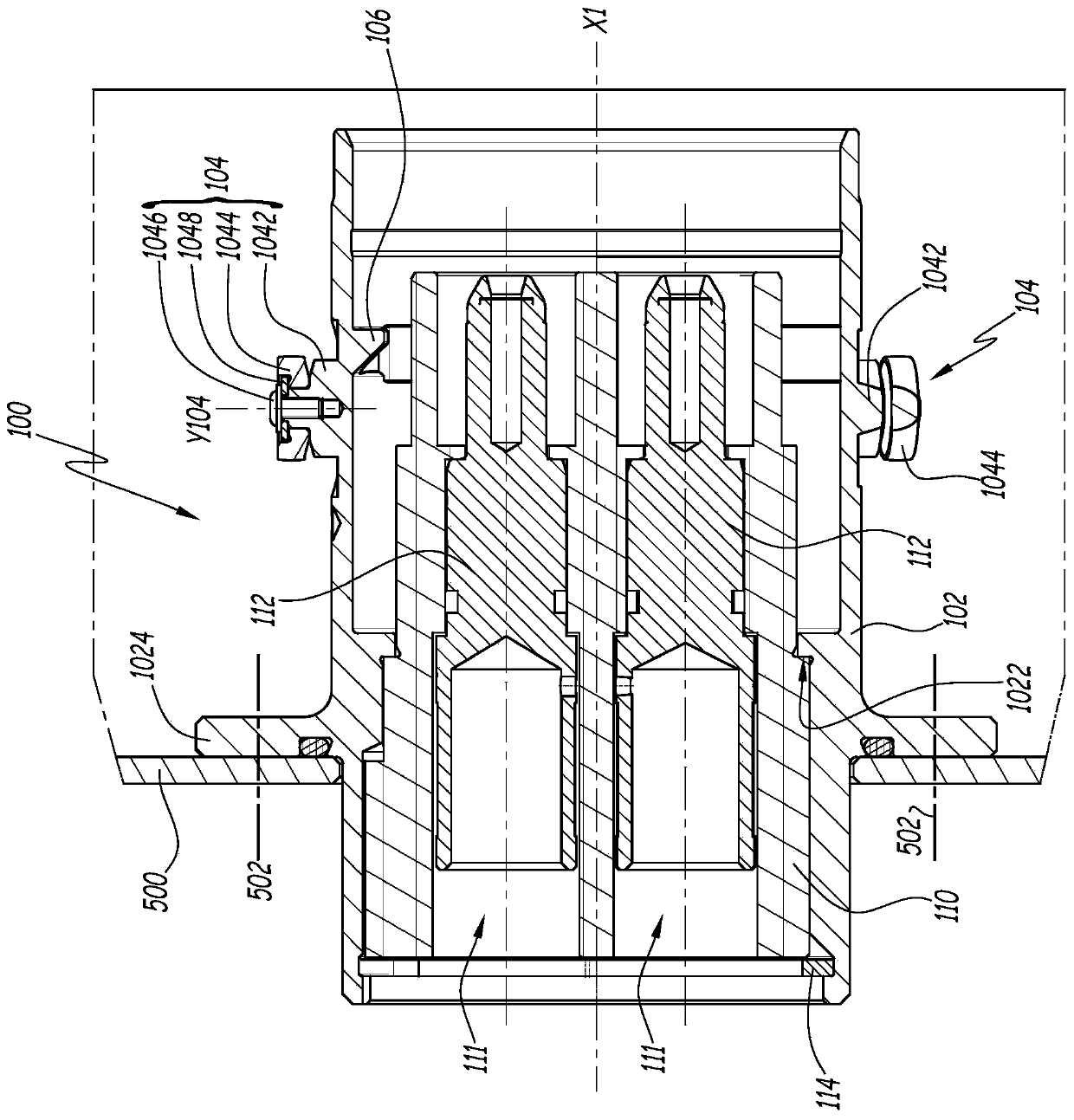

[0038] like figure 1 The female element 100 shown in the decoupled state belongs to Figure 5 The electrical connector R shown in, and hereinafter the electrical connector R is also included in the Figure 2 to Figure 4 The male element 200 is shown in a decoupled state.

[0039] The female element 100 has an overall cylindrical structure centered on the axis X1. The female element 100 comprises an outer body 102 on which three locking pins 104 are fixedly positioned and directed radially outwards. Each locking pin 104 extends along an axis Y104 radial to the axis X1 and comprises a hub 1042 formed in one piece with a main body 102, a rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com