In-plane modal circumferential traveling wave rotary type ultrasonic motor

An ultrasonic motor, rotary technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. Difficult to achieve high torque, low working reliability and other problems, to achieve the effect of simple structure, easy to realize and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

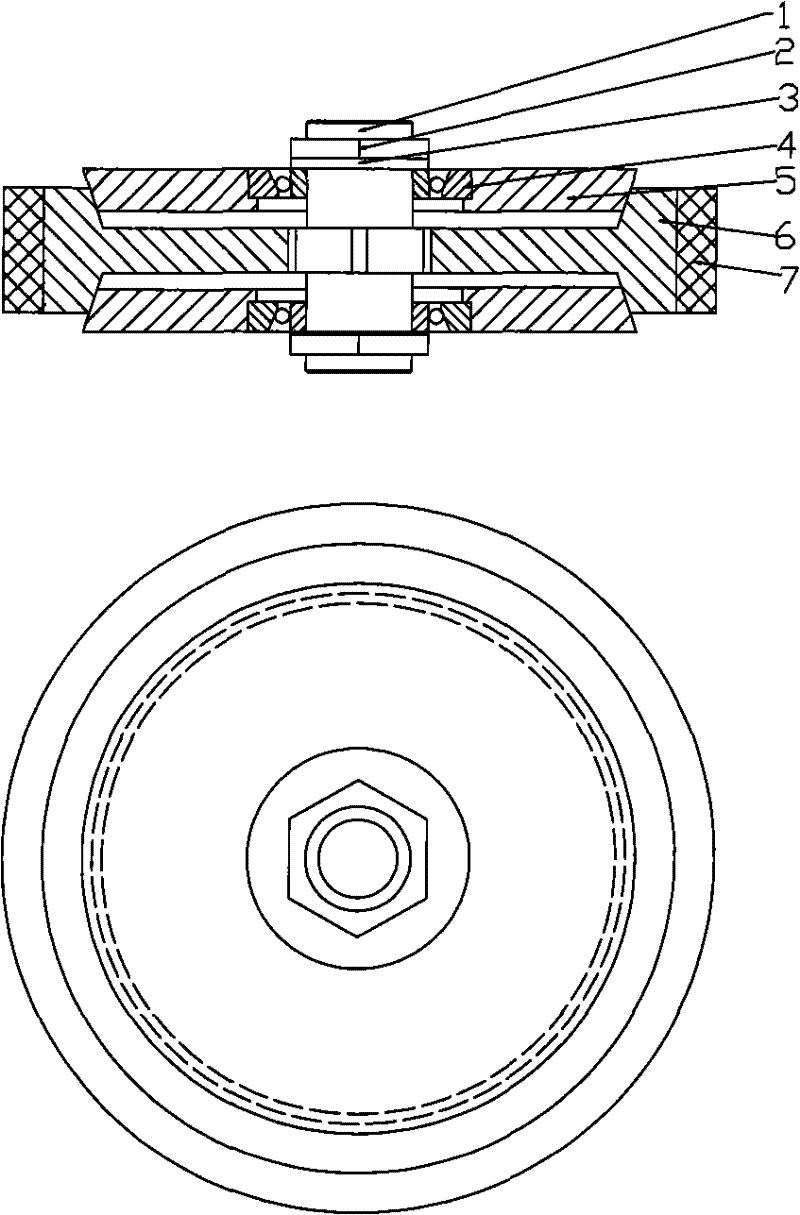

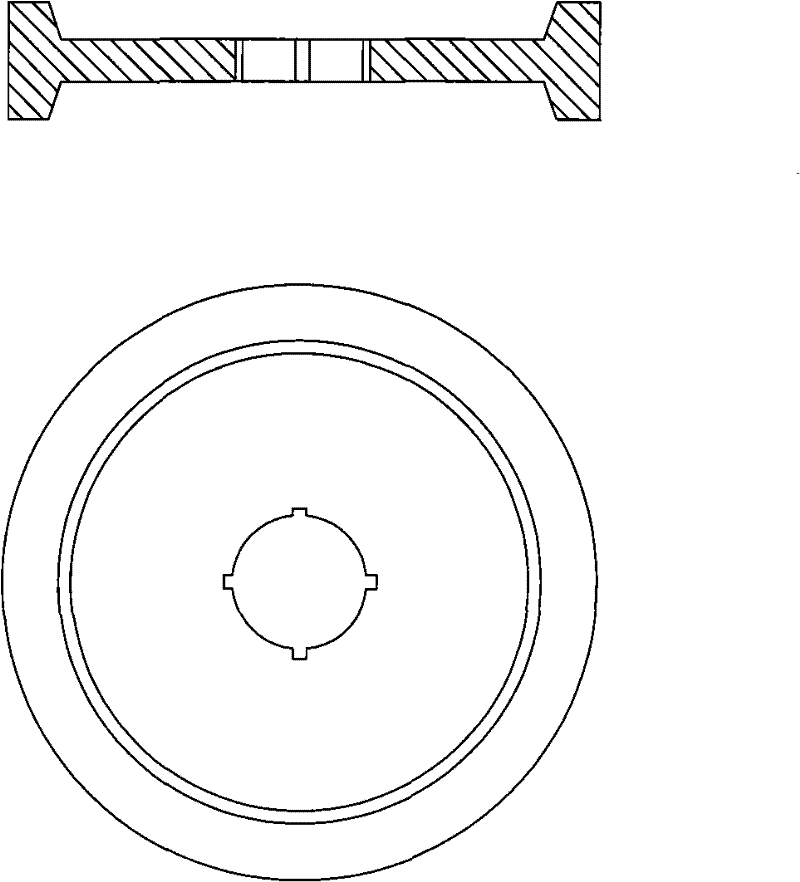

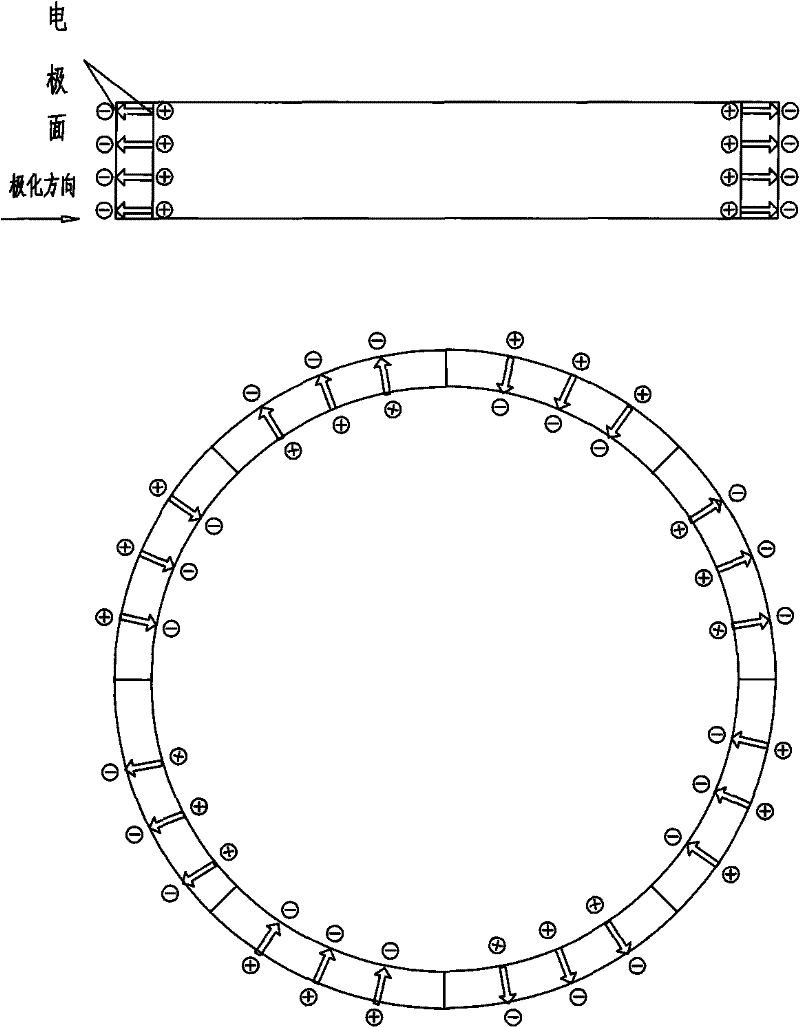

[0020] Such as Figure 1 to Figure 5 As shown, an in-plane mode circumferential traveling wave rotary ultrasonic motor includes a vibrator and a rotor 5 arranged on the inner surface of the vibrator. A preload mechanism capable of adjusting the preload is arranged between the vibrator and the rotor 5. The vibrator includes The piezoelectric ceramic ring 7 and the metal elastic body 6 arranged inside the piezoelectric ceramic ring 7, the metal elastic body of the vibrator is in the shape of a thin truncated cone, and the contact area between it and the rotor 5 is in the shape of a truncated cone. The inner ring surface of the piezoelectric ceramic ring 7 is bonded to the outer ring surface of the metal elastic body 6 by an adhesive. The pre-tightening mechanism includes a fastening bolt 1 inserted at the rotating shaft of the vibrator and the rotor 5 , a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com