Full-state air-to-air missile front cabin air pressure test device

An air-to-air missile, all-state technology, applied in the direction of ammunition testing, ammunition, weapon accessories, etc., to meet the structural and economical effects

Inactive Publication Date: 2009-11-18

CHINA AIR TO AIR MISSILE INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are no reports of similar experiments at home and abroad

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

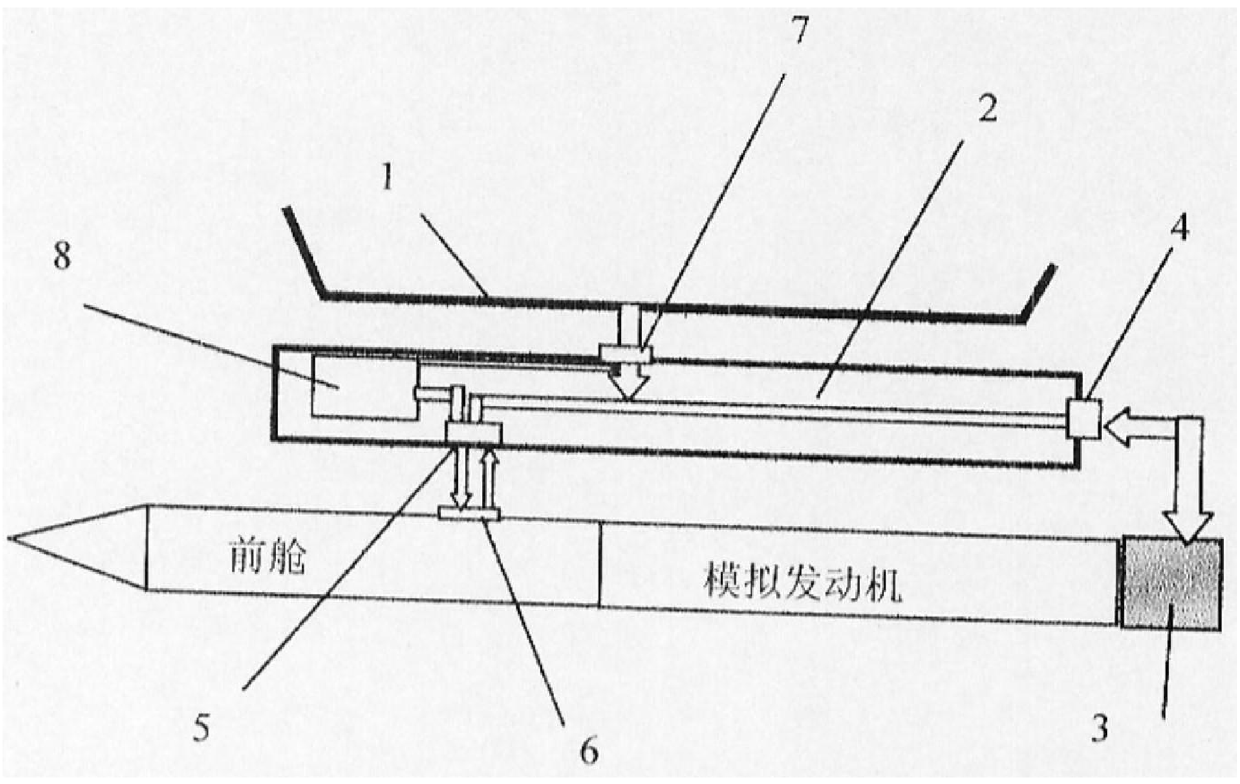

[0007] The present invention will be described in further detail below. Referring to Fig. 1, the high voltage test device of the present invention includes carrier 1 and

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the air-to-air missile system test technology, and relates to a device for air testing the front cabin of the full-state air-to-air missile, in particular to a high-pressure test device for the front cabin of the full-state air-to-air missile. Cable connectors and cables were installed on the original launching device, and a 57-volt power supply was installed on the simulated rear missile body, so that the aircraft, the front cabin of the missile and the 57-volt power supply established a second-level functional connection except for the launch control function. The invention can carry out the interception and tracking test of the real target by the front cabin of the air missile without changing the composition and technical state of the front cabin of the active radar guided air-to-air missile before launch.

Description

Technical Field The invention belongs to air-to-air missile system test technique, relate to a kind of air-to-air missile front cabin to full state air-to-air missile A device for testing, in particular to a device for applying high pressure in the air to the front cabin of a full-state air-to-air missile. Background technique Active radar type air-to-air missile in the development process is before target test, whether it still has quality through static test In particular, there are still many uncertainties about whether the real target can be reliably guided after launch. Step by step according to the test The principle of advancement, puts forward the state in the air before launch, without changing the composition and technology of the front cabin of the active radar-guided air-to-air missile State (including hot battery), the need to conduct interception and tracking experiments on real targets. While carrying out the above test, it is necessary to solve the pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F42B35/00F41G7/00

Inventor 刘未学徐和仁

Owner CHINA AIR TO AIR MISSILE INST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com