Prestressed reinforced membrane structural body and combined type prestressed reinforced membrane structural body

A technology of prestressed and reinforced membranes, which is applied in the direction of load-bearing elongated structural members, structural elements, building components, etc., and can solve the problem of limited bearing capacity, rigid pipes that are difficult to apply prestressed steel, and situations where stress cannot be applied, etc. problems, achieve the effect of reducing load, avoiding instability problems, and convenient and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

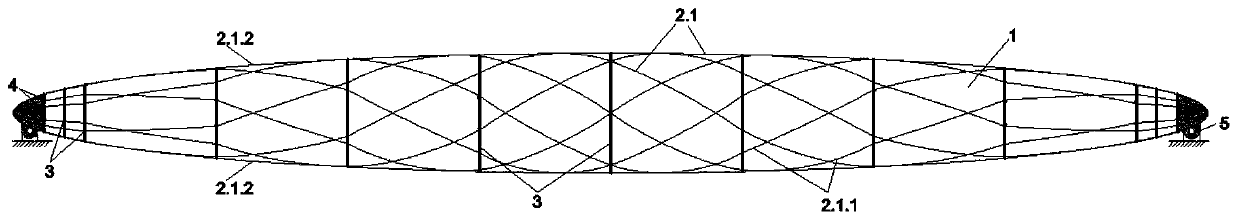

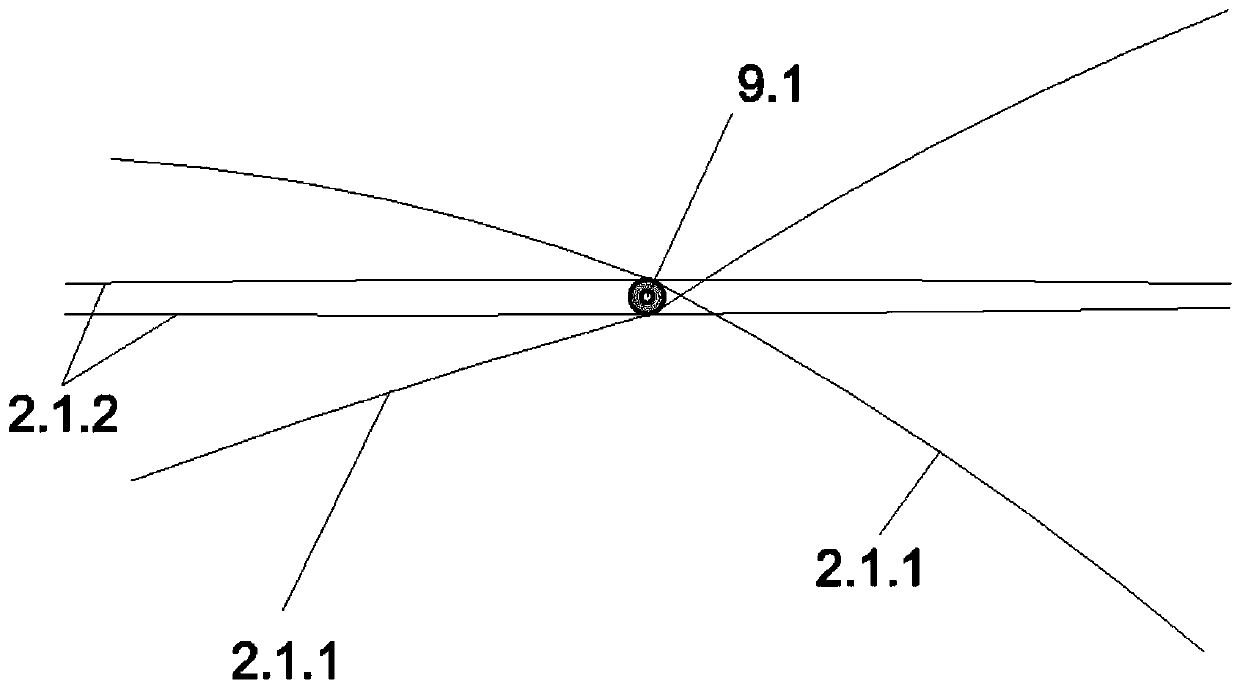

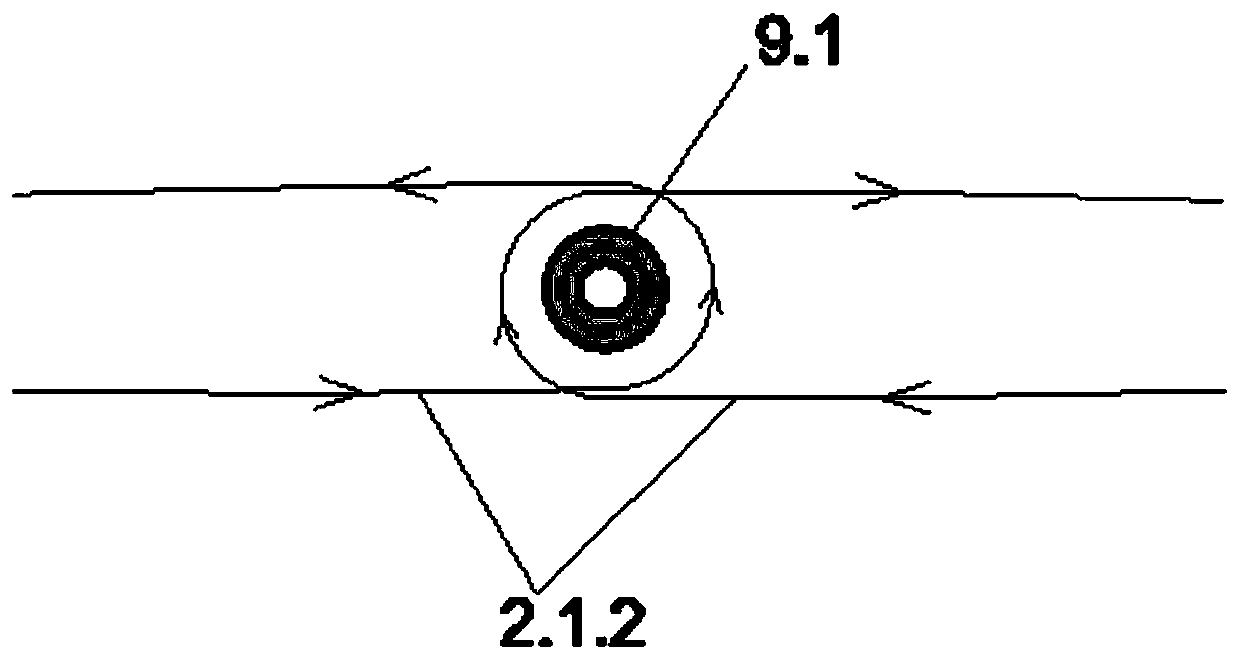

[0065] Such as figure 1 As shown, the prestressed reinforced membrane structure in this embodiment consists of a capsule 1 , a flexible reinforced skeleton 2 , an annular rigid member 3 , and a connector 5 . The capsule body 1 is an ellipsoid, or a curved surface of revolution whose generatrix is a parabola. The capsule body is a membrane structure with more than one layer, and the annular rigid member can be made of steel or other high-strength materials. The inner side of the annular rigid member 3 is circular so as to match the outer wall of the capsule 1 . The flexible reinforced skeleton 2 adopts high-strength cable materials such as prestressed steel strands or FRP; The principal stress line of the capsule changes, and ring-shaped rigid members are arranged at both ends of the capsule from the point where the included angle changes to zero, and the included angle does not change anymore; an annular rigid member can also be installed in the middle of the capsule to fa...

Embodiment 2

[0070] Such as Figure 10 As shown, the difference between this embodiment and the first embodiment is that the structure body in this embodiment adopts a cylindrical capsule with a cylindrical middle part and hemispherical ends. A pulley 3.1 is welded on the ring-shaped rigid member 3, and the helically wound flexible cable bypasses the pulley and changes its direction to be arranged along the plain lines at both ends of the capsule body; beam structure such as Figure 10 , continuous beam such as Figure 11 or a cantilever beam structure such as Figure 12 .

[0071]The flexible cable in this embodiment can be replaced by fiber cloth, and the fiber cloth is densely spread on the surface of the capsule body, and the laying direction is the same as that of the above-mentioned flexible cable. The fiber cloth is firmly glued at the joints and the spherical areas at both ends, and the contact surface between the fiber cloth arranged along the capsule element line and the spir...

Embodiment 3

[0073] Such as Figure 13 As shown, the difference between this embodiment and the second embodiment is that the capsule 1 used in the structure in this embodiment is an annular capsule, and the anchor 4 is arranged on a ring-shaped rigid member sleeved outside the capsule. , the connector 5 is welded with the annular rigid member 3, the angle between the interlaced winding cable 2.1.1 and the plain line of the formed capsule is constant, refer to the angle of the principal stress line after the capsule is formed; complete the arrangement of the flexible reinforced skeleton 2 Finally, the capsule is inflated, and the prestress of the flexible cable or fiber cloth is established. The structure shown in the figure can be used as a bicycle rim, which can reduce the weight of the vehicle.

[0074] The capsule in this embodiment can also be replaced by a semi-annular capsule or a curved capsule with varying curvature, and the flexible reinforced skeleton at both ends is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com