Method for mfg. fluorescent tubes

A technology for fluorescent tubes and manufacturing methods, which is applied in the direction of discharge tube/lamp manufacturing, tube/lamp screen manufacturing, cold cathode manufacturing, etc., and can solve the problem that the powder coating process cannot be completed with high quality, the powder slurry cannot be evenly coated, and the Realize problems such as powder coating of lamp tubes, and achieve the effect of satisfying the structure, good color temperature and improving light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

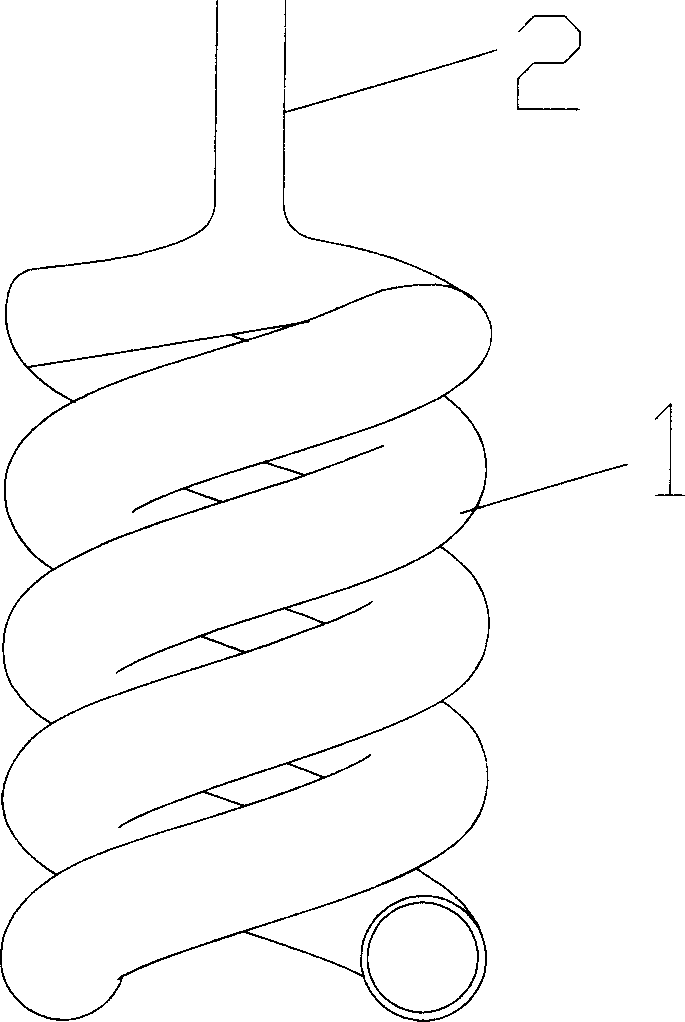

[0018] Present embodiment adopts the fluorescent lamp tube of diameter of φ7mm, 4 spirals, as figure 1 As shown, a glass tube 2 is connected to the top of the spiral fluorescent tube 1, the diameter of the glass tube 2 is 3.5 mm, and the inside of the glass tube 2 communicates with the inside of the fluorescent tube 1. When applying powder, the fluorescent powder slurry is sucked from a nozzle of the spiral fluorescent tube 1. At this time, press the top of the connected glass tube 2 with your fingers to make it sealed until the process of sucking the slurry is completed. Remove the finger that seals the top of the exhaust pipe, and the phosphor powder slurry can smoothly flow out from the nozzle of the spiral fluorescent tube 1 under its own gravity and the atmospheric pressure on it, thereby completing the powder coating process.

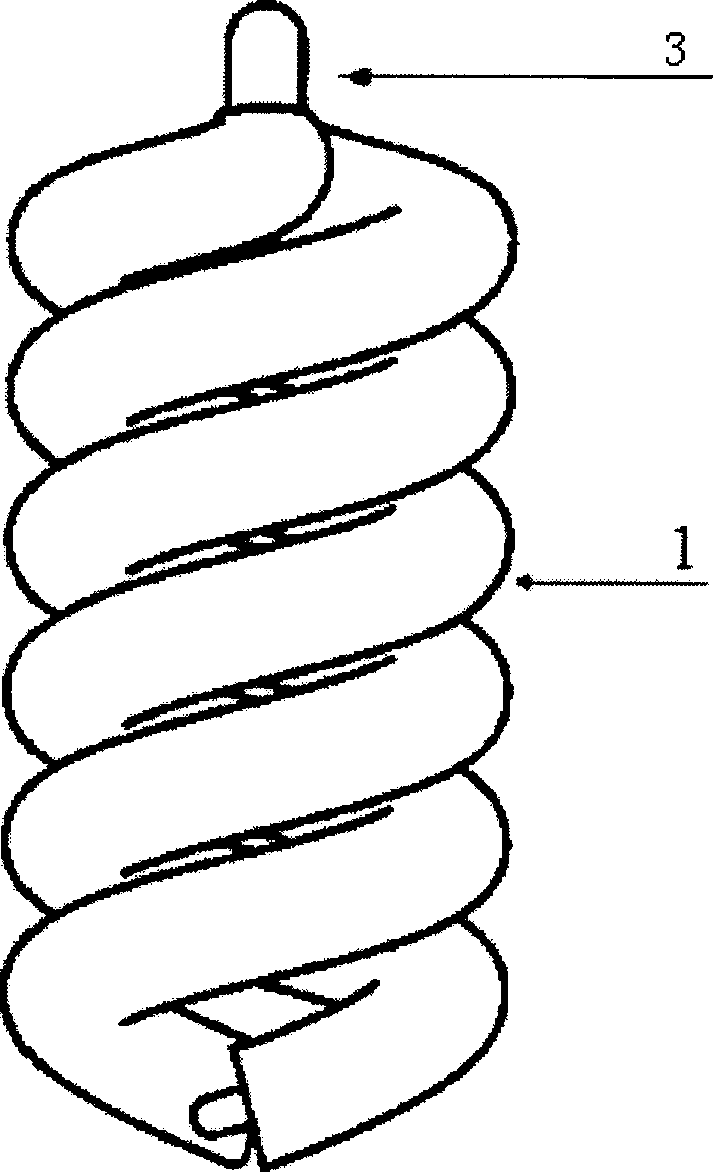

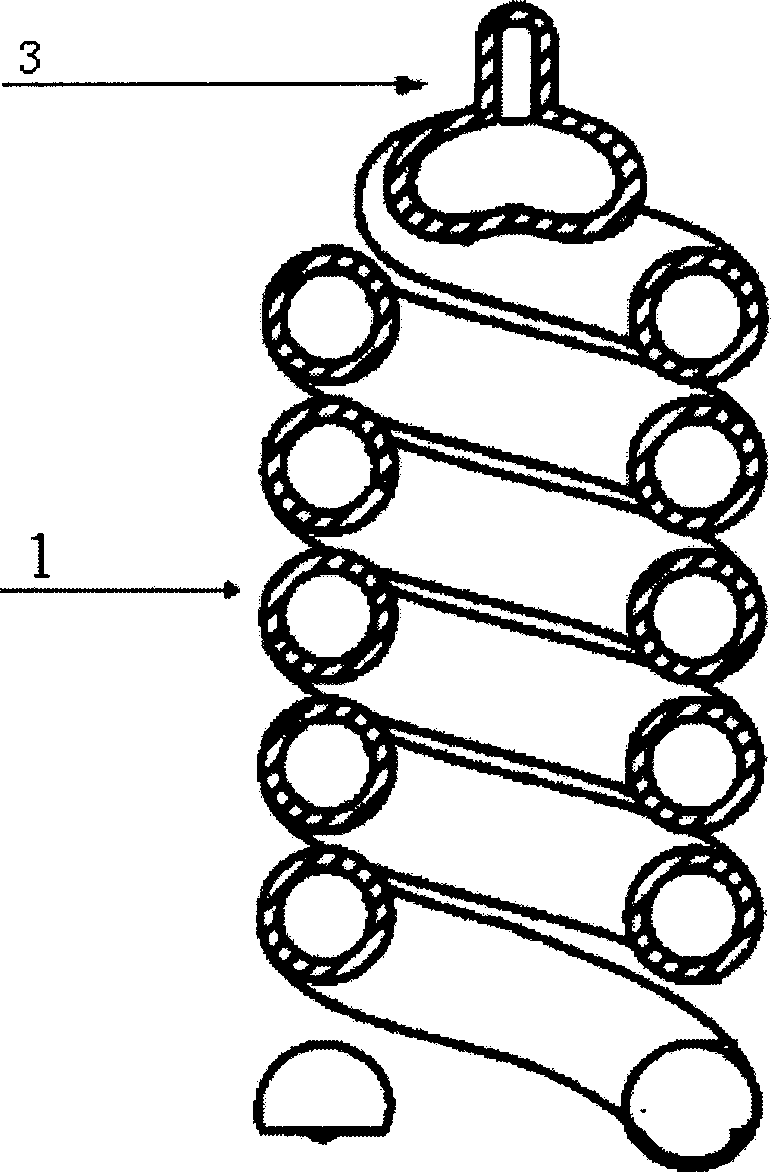

[0019] After the exhaust process, when the mercury is roasted, the top of the fluorescent tube 1 can retain a top bubble 3 with a height of 2.5mm...

Embodiment 2

[0021] Present embodiment adopts the fluorescent lamp tube of diameter of φ 7mm, 5 spirals, and the diameter of glass tube 2 is 1.5mm, and the method of powder coating is the same as that of embodiment 1, after the exhaust process, when roasting mercury and burning the tip, the top of fluorescent lamp tube 1 A top bubble 3 with a height of 3 mm can be reserved (see figure 2 , 3 ), the top bubble 3 can be used as a cold end of the spiral lamp tube, which is beneficial to the improvement of light efficiency.

Embodiment 3

[0023] Present embodiment adopts the fluorescent tube of φ 9mm tube diameter, more than 5 helixes, and the tube diameter of glass tube 2 is 5.5mm, and the powder coating method is the same as embodiment 1, and after the exhaust process, when roasting mercury, the fluorescent tube 1 A top bubble 3 with a height of 3mm can be reserved at the top (see figure 2 , 3 ), this bubble 3 can be used as a cold end of the spiral lamp tube, which is beneficial to the improvement of light efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com