Spread flavored fermented milk and preparation method thereof

A fermented milk and smear-type technology, which is applied to bacteria and lactobacilli used in dairy products and food preparation, can solve the problems of inconvenient storage and transportation of fermented milk, increase transportation and storage costs, and reduce the precipitation of whey , enhance the creaminess and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

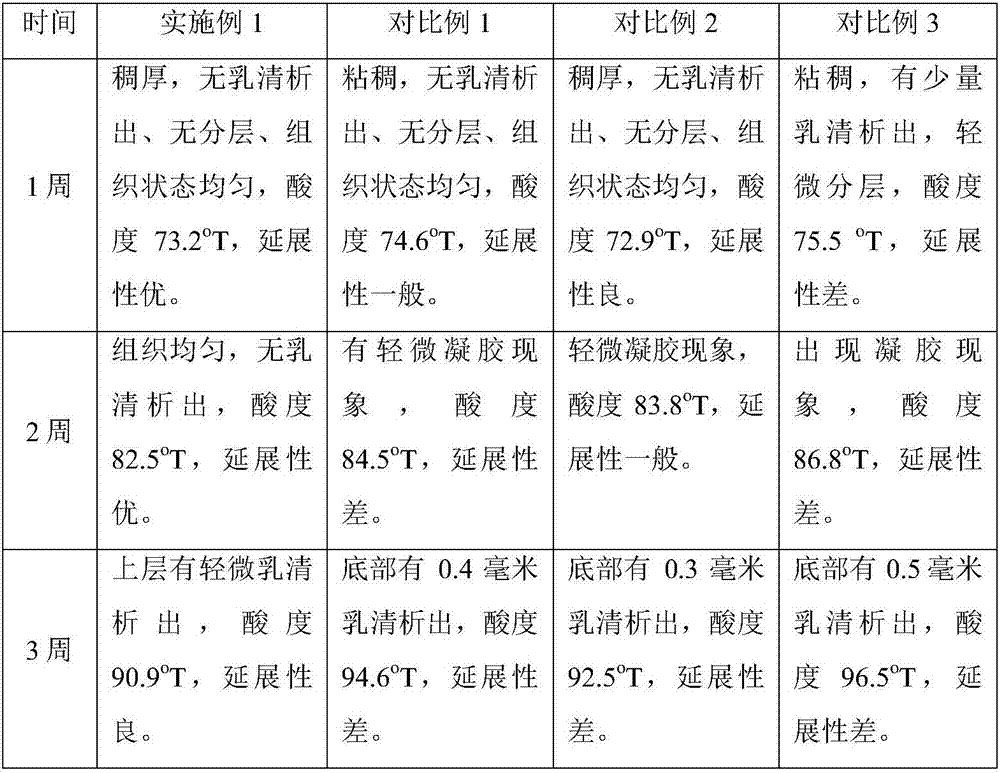

Examples

Embodiment 1

[0025] A smear-type flavored fermented milk, including the following raw materials in percentage by weight: raw milk 60%, fermented bacteria 0.005%, white sugar 8%, skimmed milk powder 2%, concentrated milk protein 3%, cooked cheese powder 0.1% , 25% cream, 0.2% condensed milk, 0.1% agar, 0.2% starch, and the balance is purified water.

[0026] The fermentation strains are Streptococcus thermophilus and Lactobacillus bulgaricus.

[0027] The preparation method of the smear-type flavored fermented milk comprises the following steps:

[0028] 1) Ingredients: Take the raw milk and heat it up to 40-50°C, add skimmed milk powder, concentrated milk protein powder, cooked cheese powder, cream, and condensed milk into the heated raw milk, mix well, let stand for 40 minutes, and then Mix white granulated sugar, agar, and starch evenly and add them to the heated raw milk, stir for 15 minutes to fully dissolve, after mixing evenly, let stand for 30 minutes, then add purified water to ma...

Embodiment 2

[0032] A smear-type flavored fermented milk, including the following raw materials in percentage by weight: 70% raw milk, 0.005% fermented bacteria, 10% white sugar, 4% skimmed milk powder, 5% concentrated milk protein, and 0.3% cooked cheese powder , 8% cream, 0.7% condensed milk, 0.5% agar, 1.0% starch, and the balance is purified water.

[0033] The fermentation strains are Streptococcus thermophilus and Lactobacillus bulgaricus.

[0034] The preparation method of the smear-type flavored fermented milk is the same as that in Example 1.

Embodiment 3

[0036] A smear-type flavored fermented milk, comprising the following raw materials in percentage by weight: raw milk 65%, fermented bacteria 0.005%, white sugar 9%, skimmed milk powder 3%, concentrated milk protein 4%, cooked cheese powder 0.2%, 15% of cream, 0.5% of condensed milk, 0.3% of agar, 0.6% of starch, and the balance is purified water.

[0037] The fermentation strains are Streptococcus thermophilus and Lactobacillus bulgaricus.

[0038] The preparation method of the smear-type flavored fermented milk is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com