Quark base mix having enhanced taste properties

A matrix composition and composition technology, applied in the field of quark cheese, can solve the problems of affecting edible characteristics, unfavorable, unsatisfactory sensory evaluation of quark cheese, etc., and achieve the effect of delaying penetration and enhancing creaminess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4

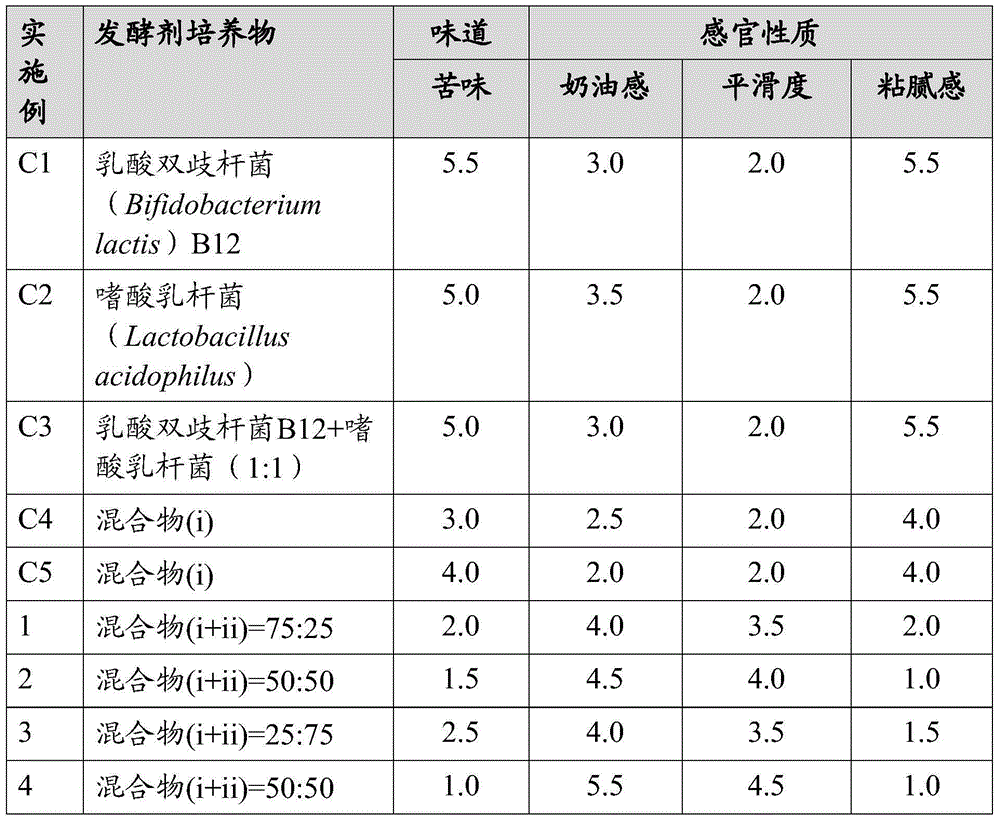

[0064] Examples 1 to 4, Comparative Examples C1 to C5

[0065] 4 kg of skim milk were treated at 88° C. for 6 minutes and the resulting protein was denatured. The mixture was mixed with lactic acid bacteria and rennet and aged at about 30°C for about 18 hours, then stirred. The fermentation product was then placed in a centrifuge and about 3.2 kg of acid whey were separated as a liquid fraction. The remaining quark cheese mix (approximately 800 g) was adjusted to a dry matter content of 18% by weight and a protein content of 12% by weight by adding cream. Example 4 differs from Example 2 in that the matrix mix is remixed ("stretched") after fermentation in a rotor-stator mixer from YTRON. The taste and organoleptic properties of the prepared product were then evaluated by a panel of 5 experienced testers on a scale from 1 (=not applicable) to 6 (=perfectly applicable). The results are summarized in Table 1. Examples 1 to 4 are according to the invention and examples C1 t...

Embodiment 5 to 7

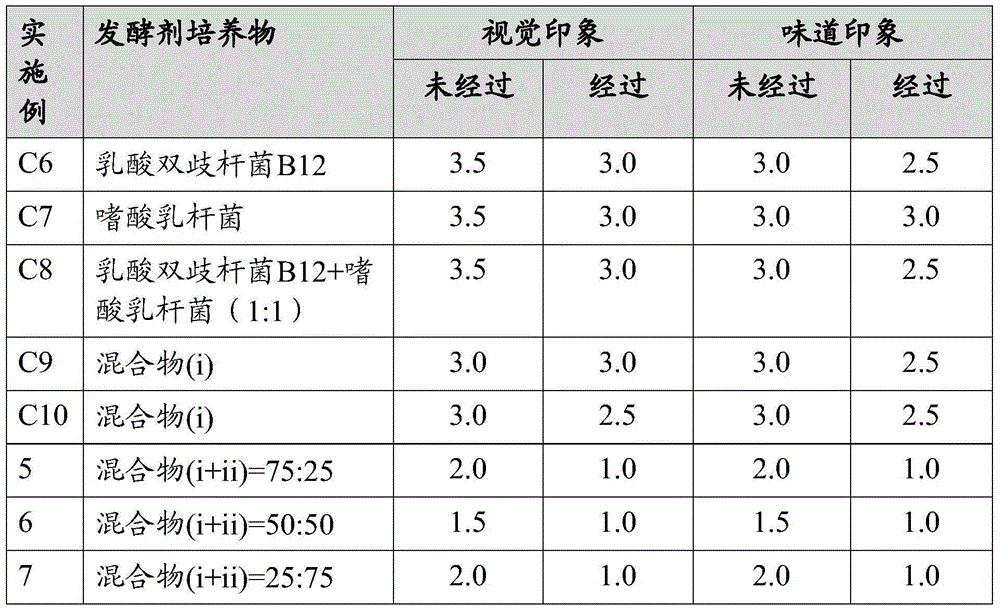

[0070] Examples 5 to 7, Comparative Examples C6 to C10

[0071] The following examples show the effect of targeted introduction of agitation energy into a fermented quark cheese base composition on its physicochemical properties. The treatment was evaluated for its effect on the tendency of the quark cheese base composition to absorb water when the fruit preparation was added and thus dull the taste. For this purpose, quark cheese base compositions prepared according to the invention based on different starter cultures were prepared in each case using 25% by weight of fruit pieces of strawberries and pineapples in sweetened preparations using a rotor from YTRON - The stator mixer is covered once before and after treatment (20°C, 15 minutes, 2500rpm) and visual inspection by a panel of 5 experienced testers after the preparations have been stored at 7°C for a period of 5 hours Both impression and taste impression were evaluated.

[0072] Visual assessment was based on a scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com