Patents

Literature

84results about "Leuconostoc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functional composition

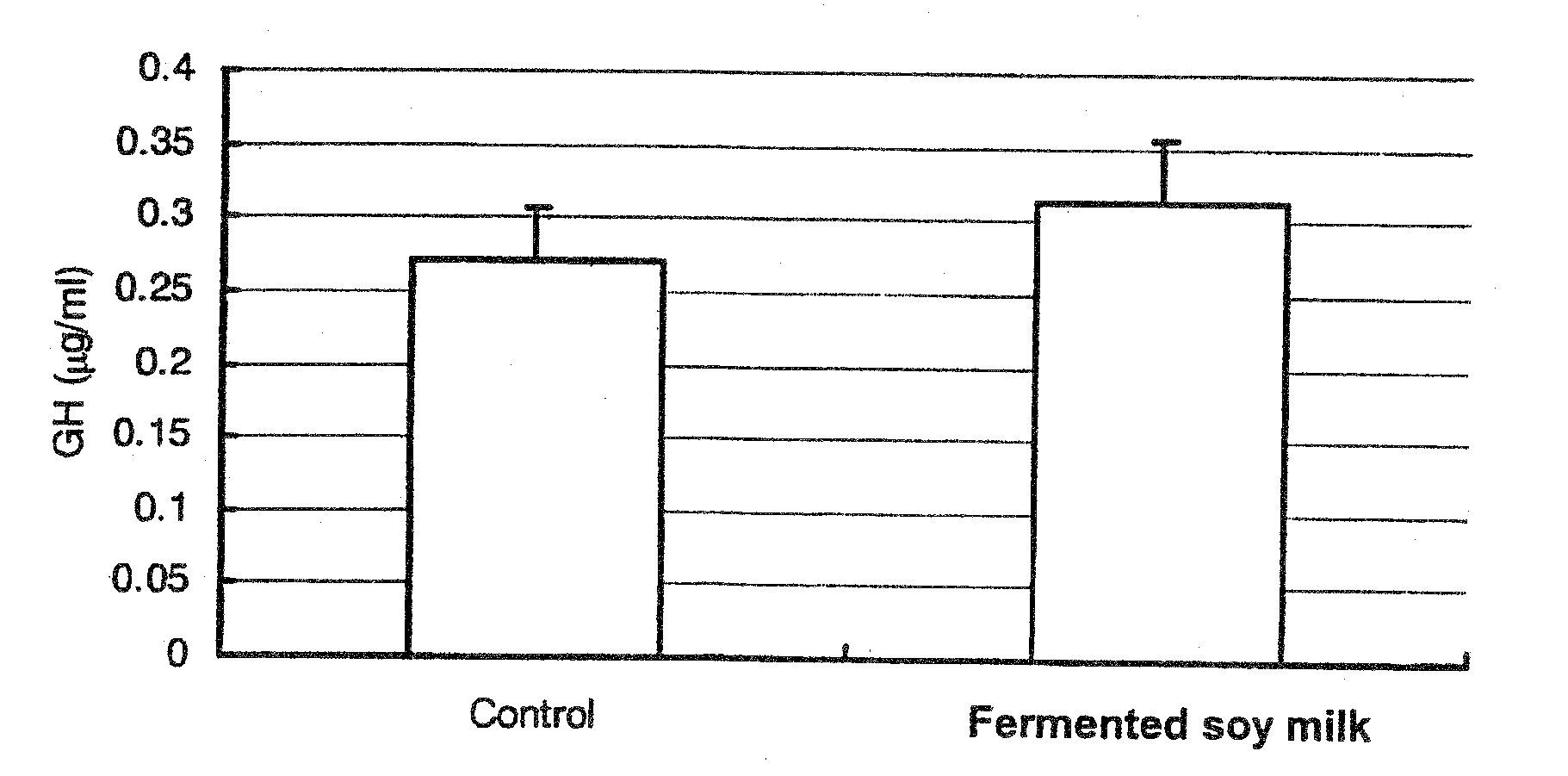

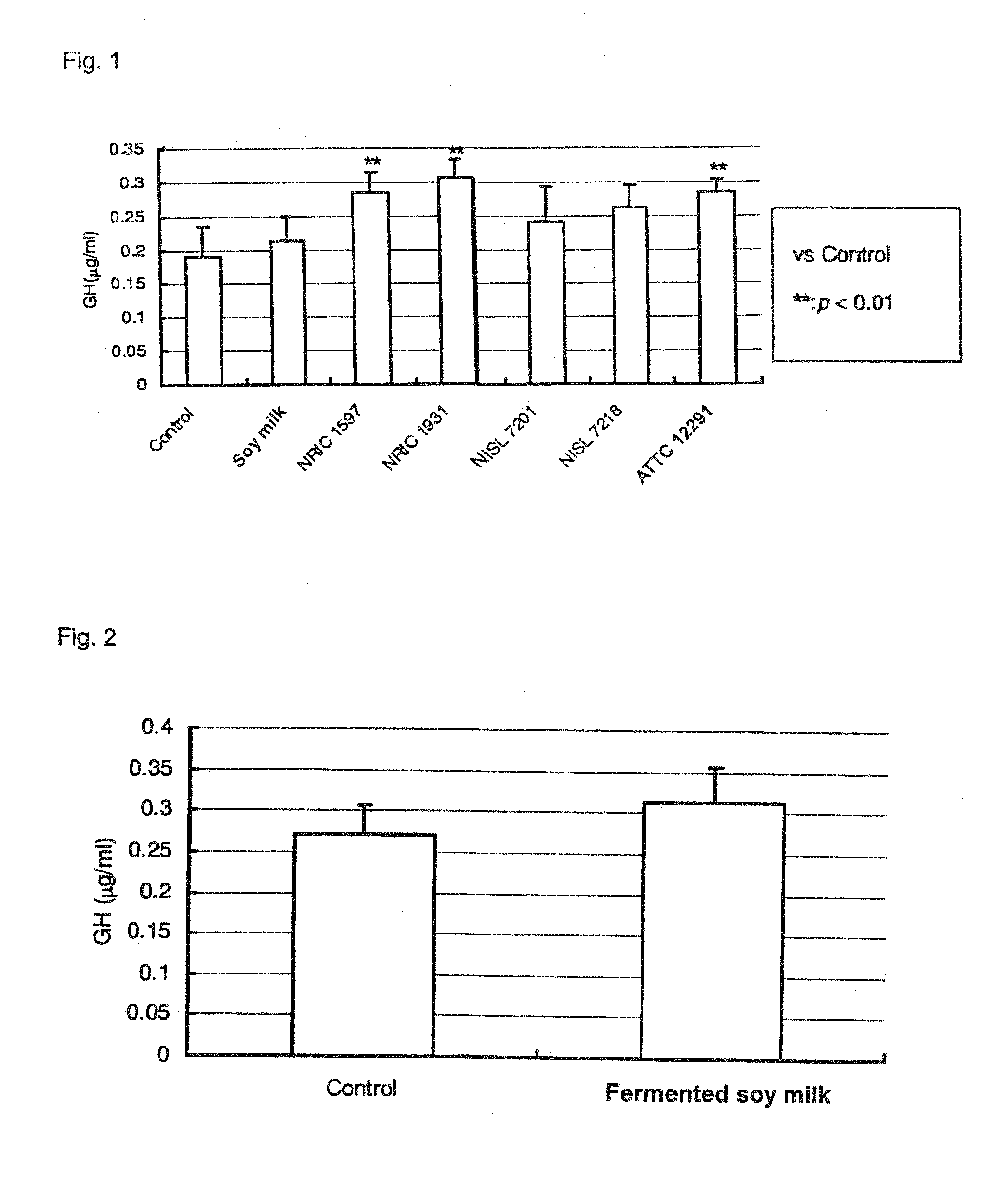

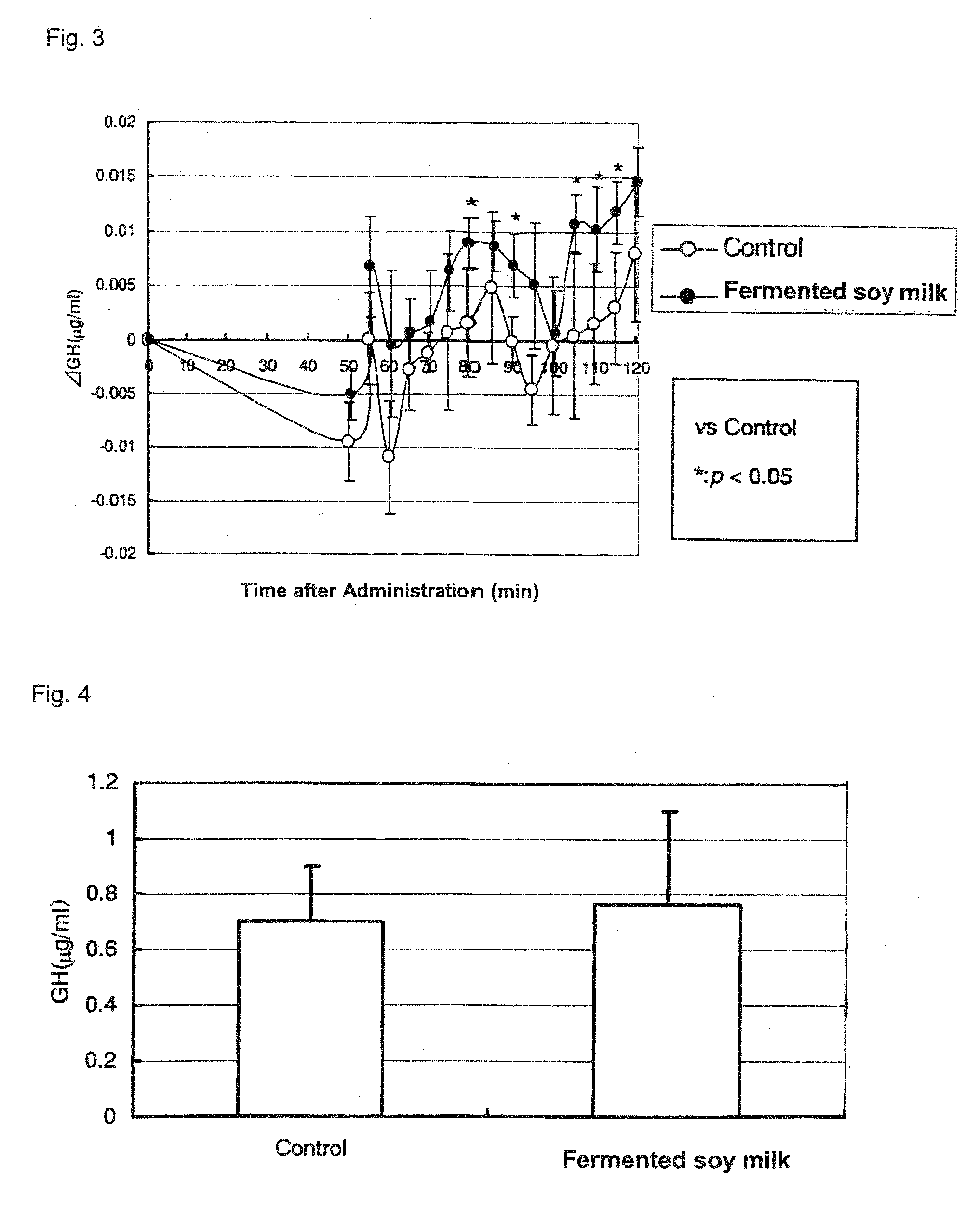

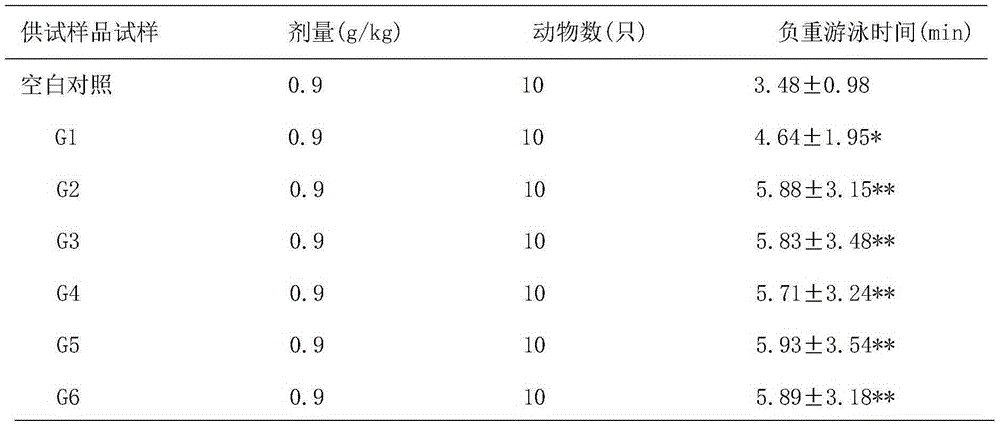

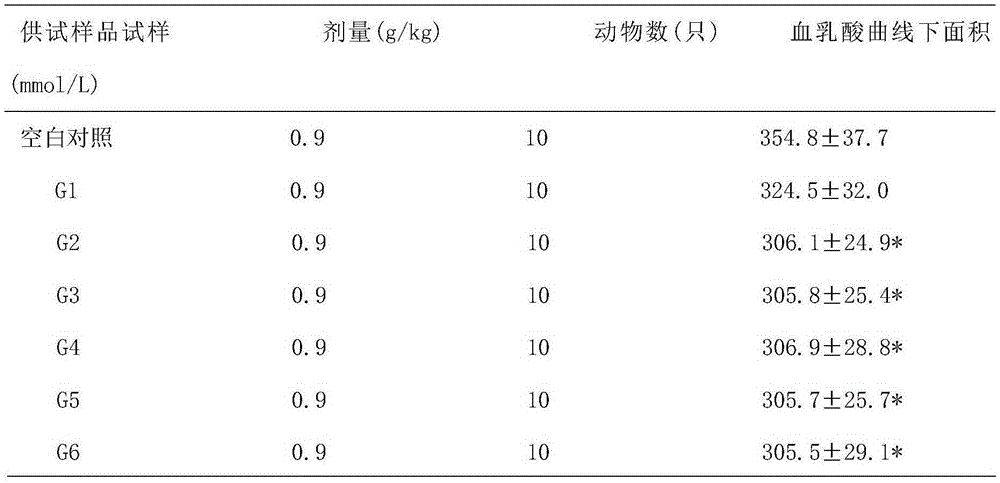

InactiveUS20080176305A1Highly safe and inexpensive and easy to ingestGood effect heath maintenanceLactobacillusAlgae medical ingredientsGrowth hormoneSecretin activity

A functional composition containing as an active ingredient a lactic acid fermented product obtained by fermenting a component of soybean origin using a lactic acid bacterium belonging to the genera Lactobacillus, Leuconostoc, or Pediococcus. It has various activities such as growth hormone secretagogue activity, fatigue accumulation preventing activity, circadian rhythm regulatory activity, reproductive behavior inducing activity, and so forth and is useful as a growth hormone secretagogue, a fatigue accumulation preventing composition, a circadian rhythm regulator, or a reproductive behavior-inducing composition.

Owner:KIKKOMAN CORP

Cheese Products

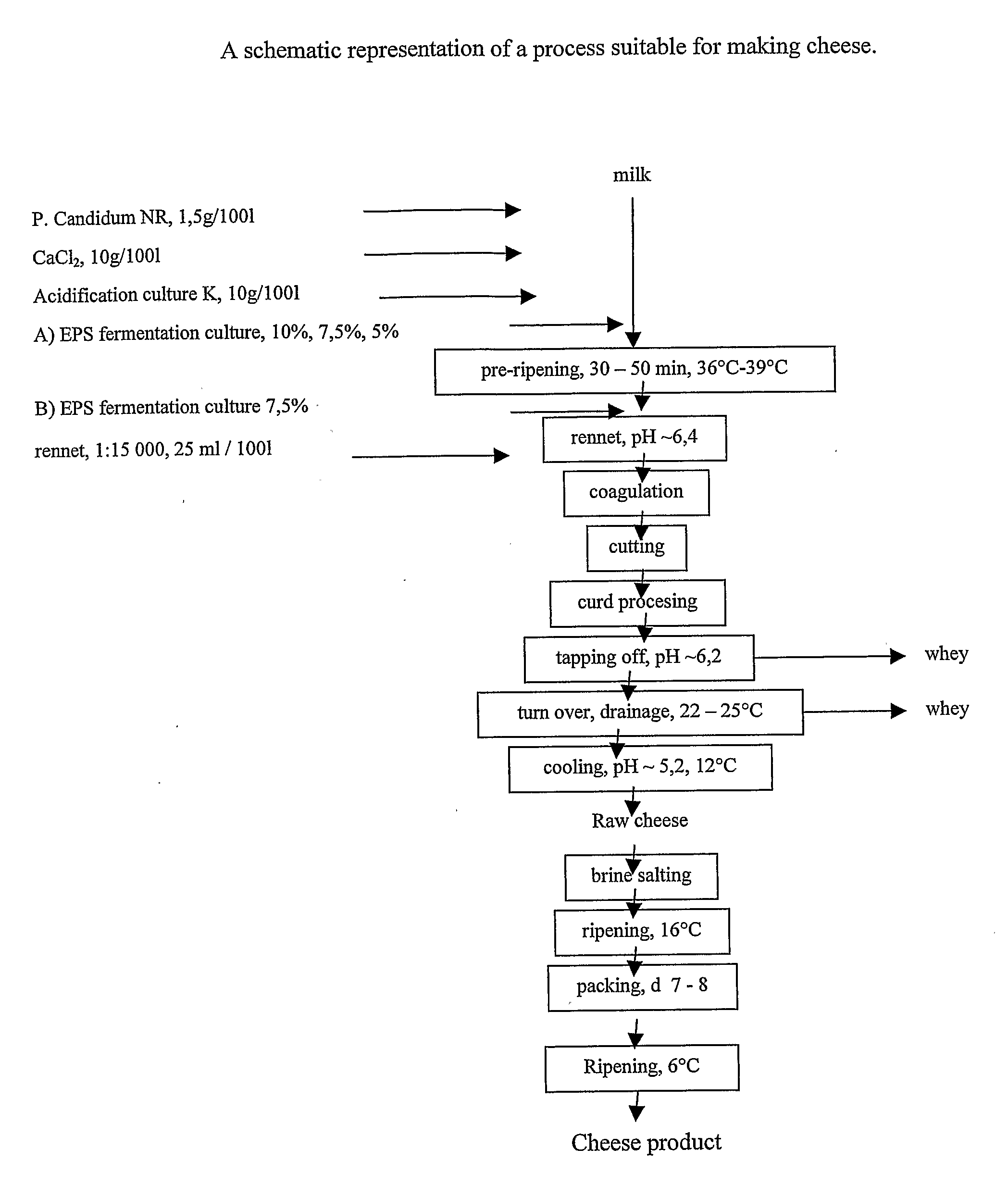

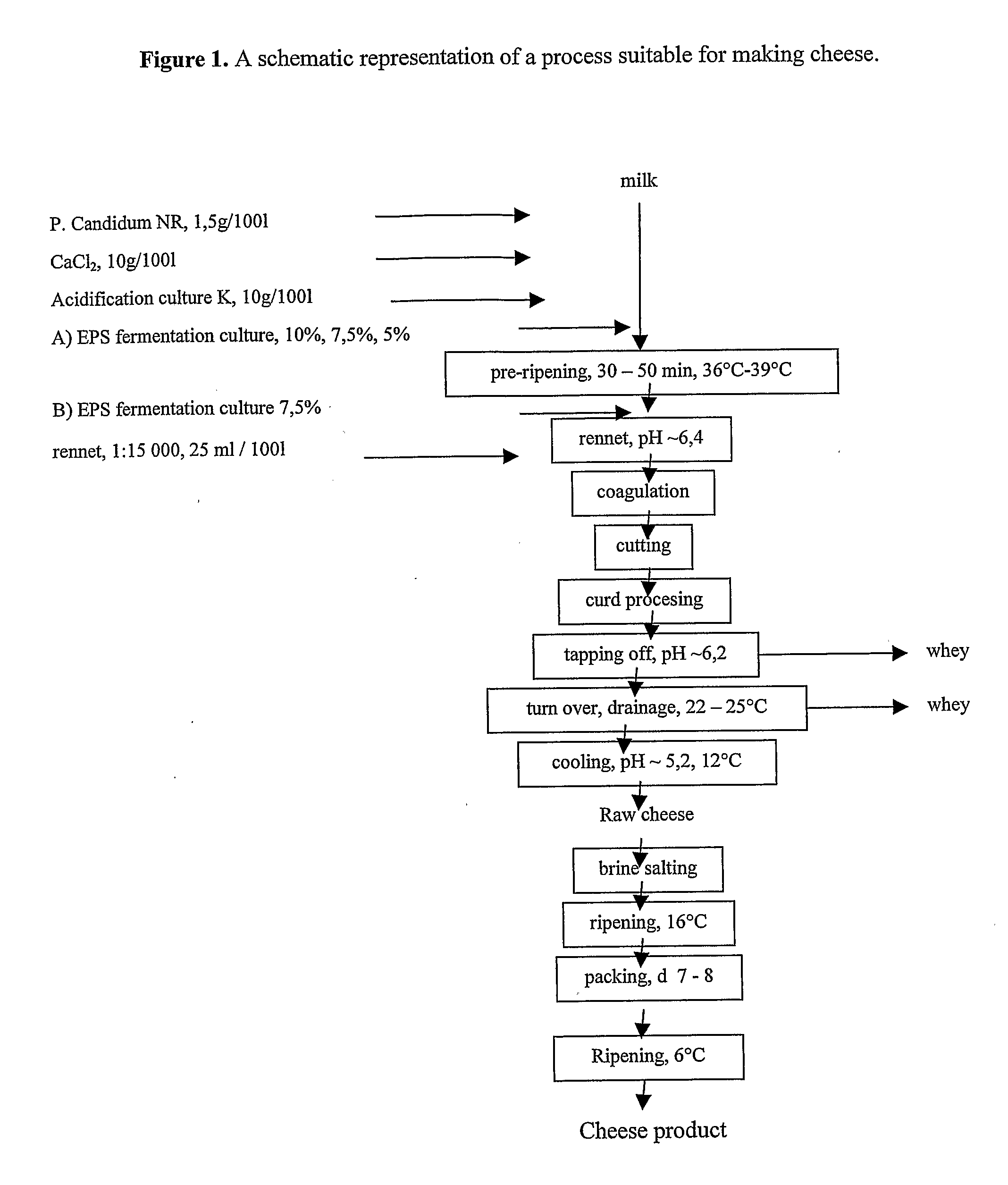

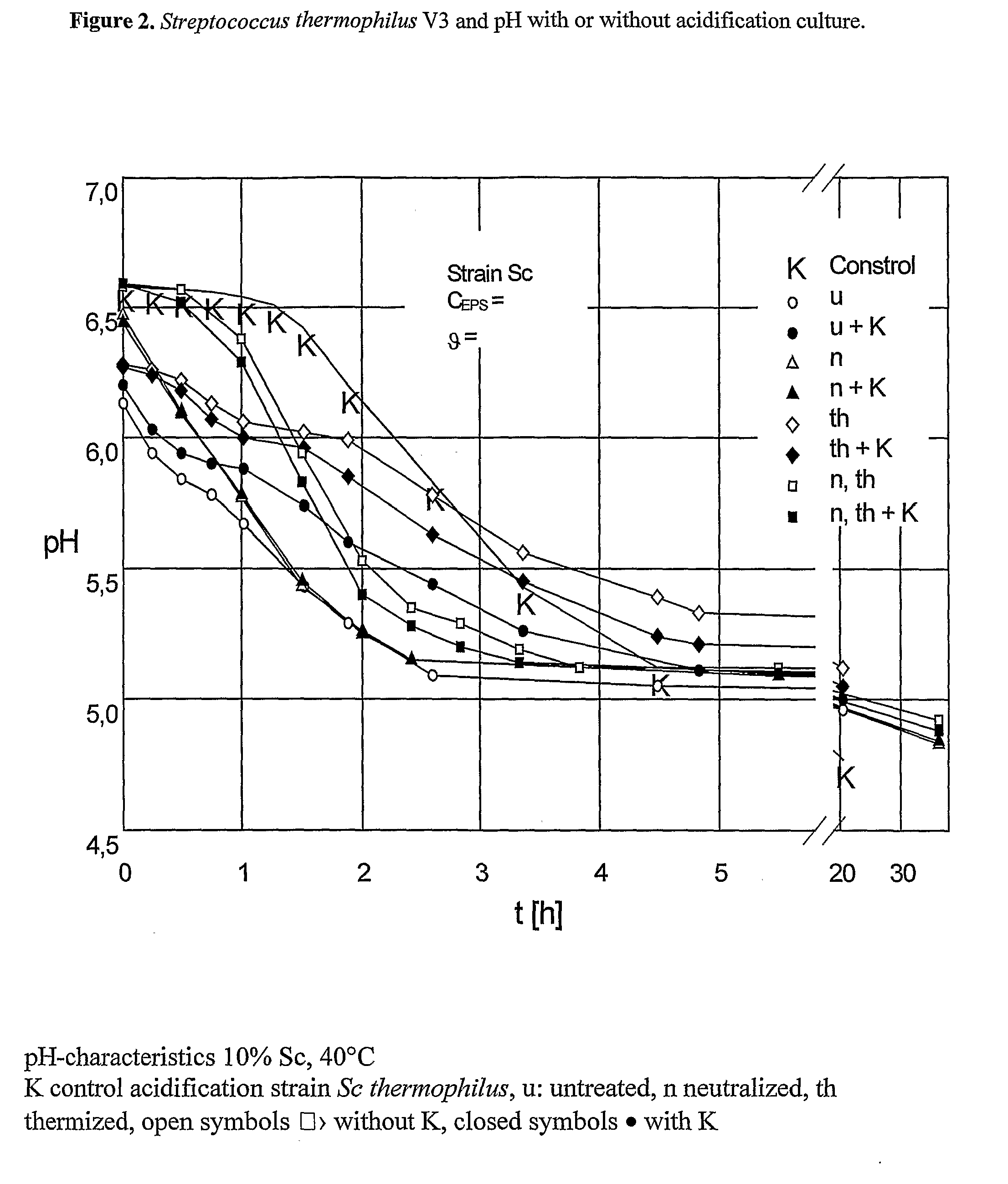

InactiveUS20080050467A1Suitable flavour and textureGood moisturizing effectMilk preparationBacteriaHealth benefitsOrganism

The present invention relates to a composition and a method of preparing cheese products with a suitable moisture level. The cheese products that have been formed using the composition are characterised with an improve at least one of aroma, flavour, mildness, consistency, texture, syneresis, body, mouth feel, firmness, viscosity, gel fracture, wheying off, structure and / or organoleptic properties, nutrition and / or health benefits. In particular, the present invention provides a composition comprising a starter acidification micro-organism and an EPS fermentation culture comprising a viable micro-organism an enzyme produced by said micro-organism and an exopolysaccharide (EPS) produced by the activity of said enzyme.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Pure grape essence ferment and production method thereof

InactiveCN105286006ARealize comprehensive utilizationPromote value-addedYeast food ingredientsLactobacillusPectinaseNeutral protease

The invention discloses pure grape essence ferment and a production method thereof. The pure grape essence ferment consists of the following raw materials in parts by weight: 50-90 parts of fresh grapes, 0-5 parts of nonfat grape skin residue powder, 0-2 parts of grape wine, 0-5 parts of high fructose corn syrup, 0-100 parts of white granulated sugar, 0-2 parts of xylooligosaccharide, 0-35 parts of L-arabinose, 0-10 parts of sugar alcohol, and an appropriate quantity of probiotics. The production method comprises the following steps of: cleaning the fresh grapes, removing stems of the cleaned fresh grapes, crushing the fresh grapes without stems, squeezing juice from the crushed grapes, adding water to grape skin residues, grinding the grape skin residues, adding pectinase, cellulase, and neutral protease, and performing enzymolysis; and enabling the probiotics to be fermented when being subjected to heat preservation, after fermenting the fermented probiotics, and performing centrifugation to remove residues so as to obtain raw pure grape essence ferment liquid. The pure grape essence ferment disclosed by the invention has the efficacies of reducing blood lipid, reducing weight, improving the antioxidant ability of organisms, regulating and balancing intestinal flora, improving immunity, resisting oxidation, promoting the beautifying of the features, promoting sleep, and delaying senescence.

Owner:周学义

Lactic acid bacteria for the treatment of food

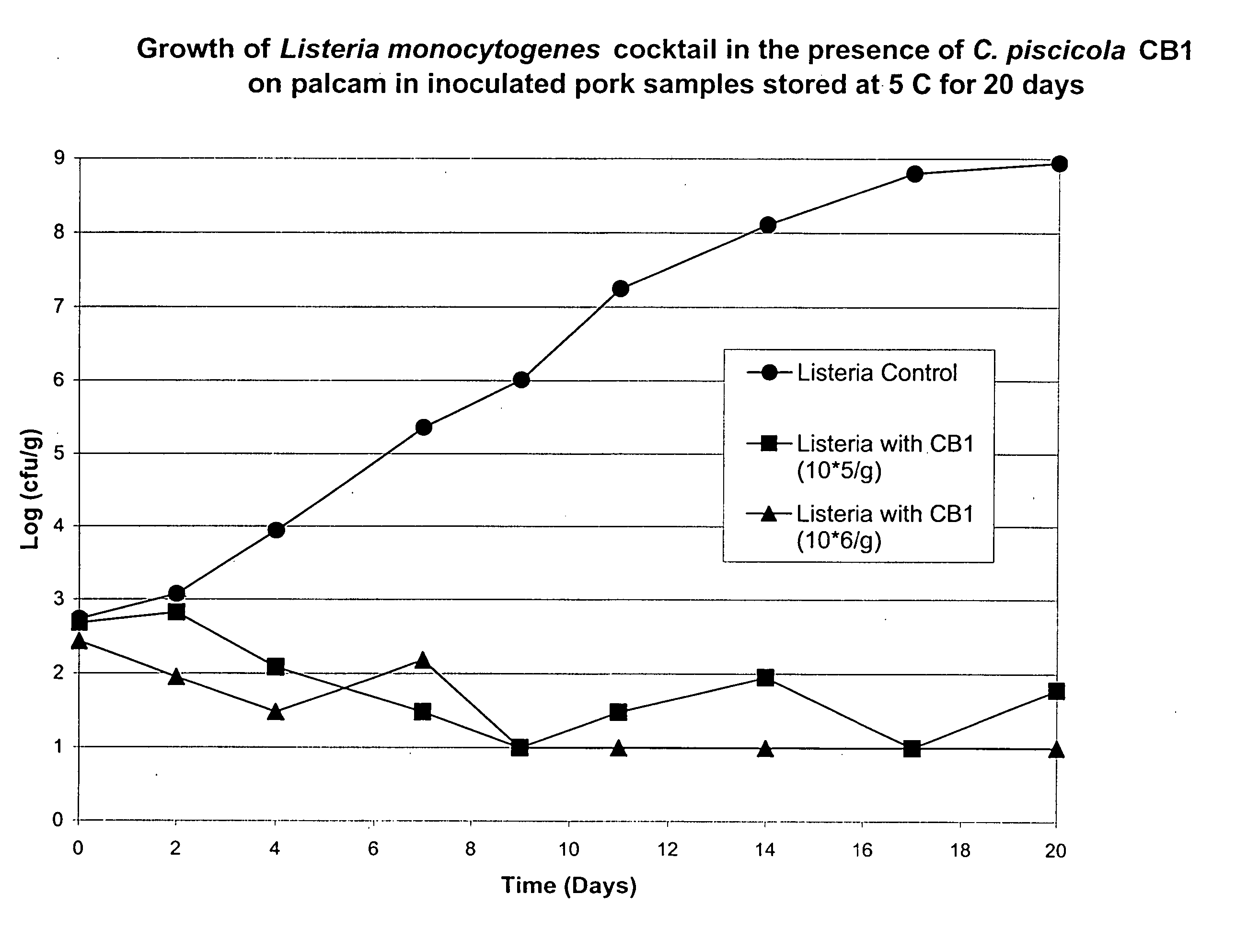

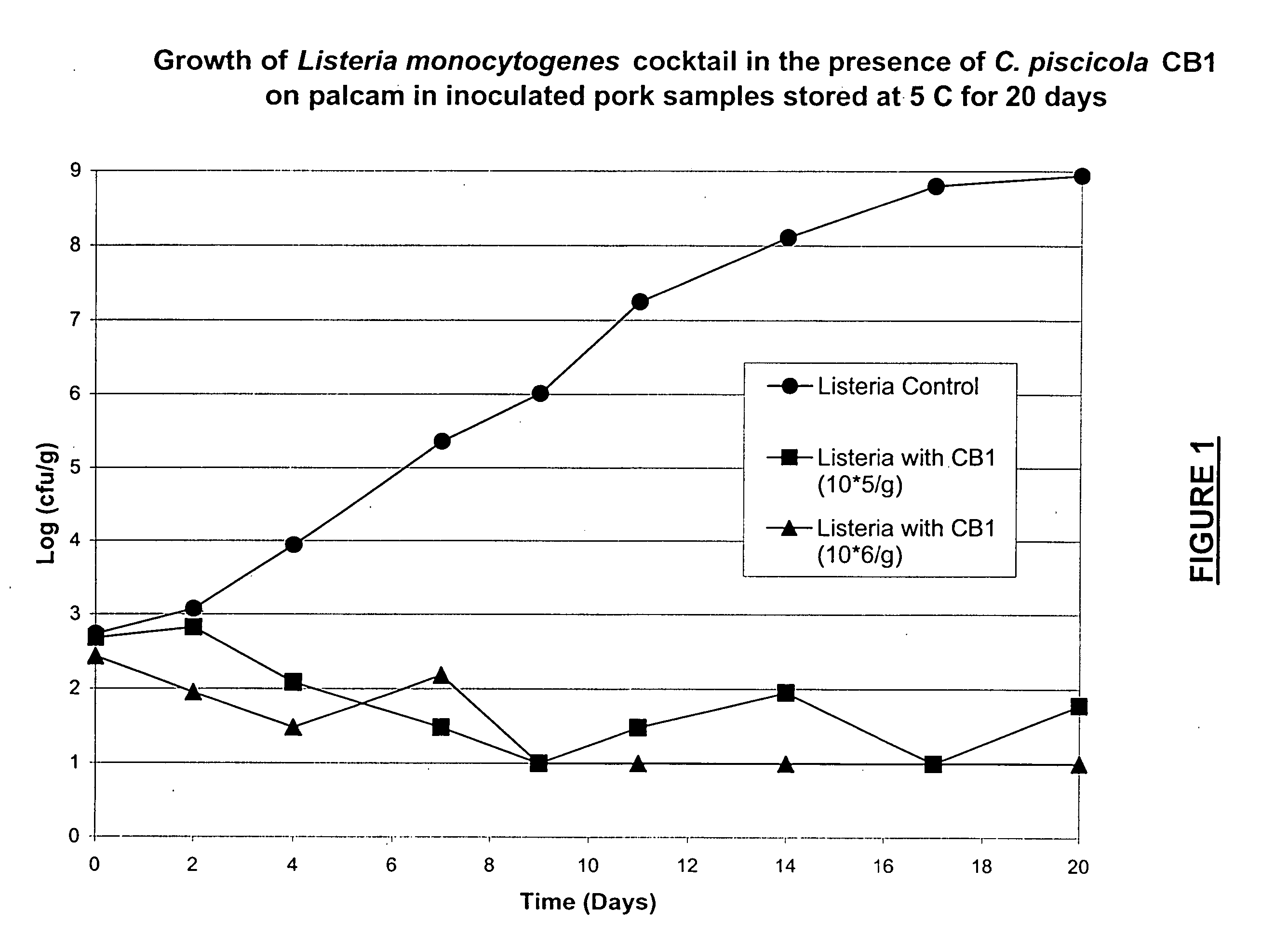

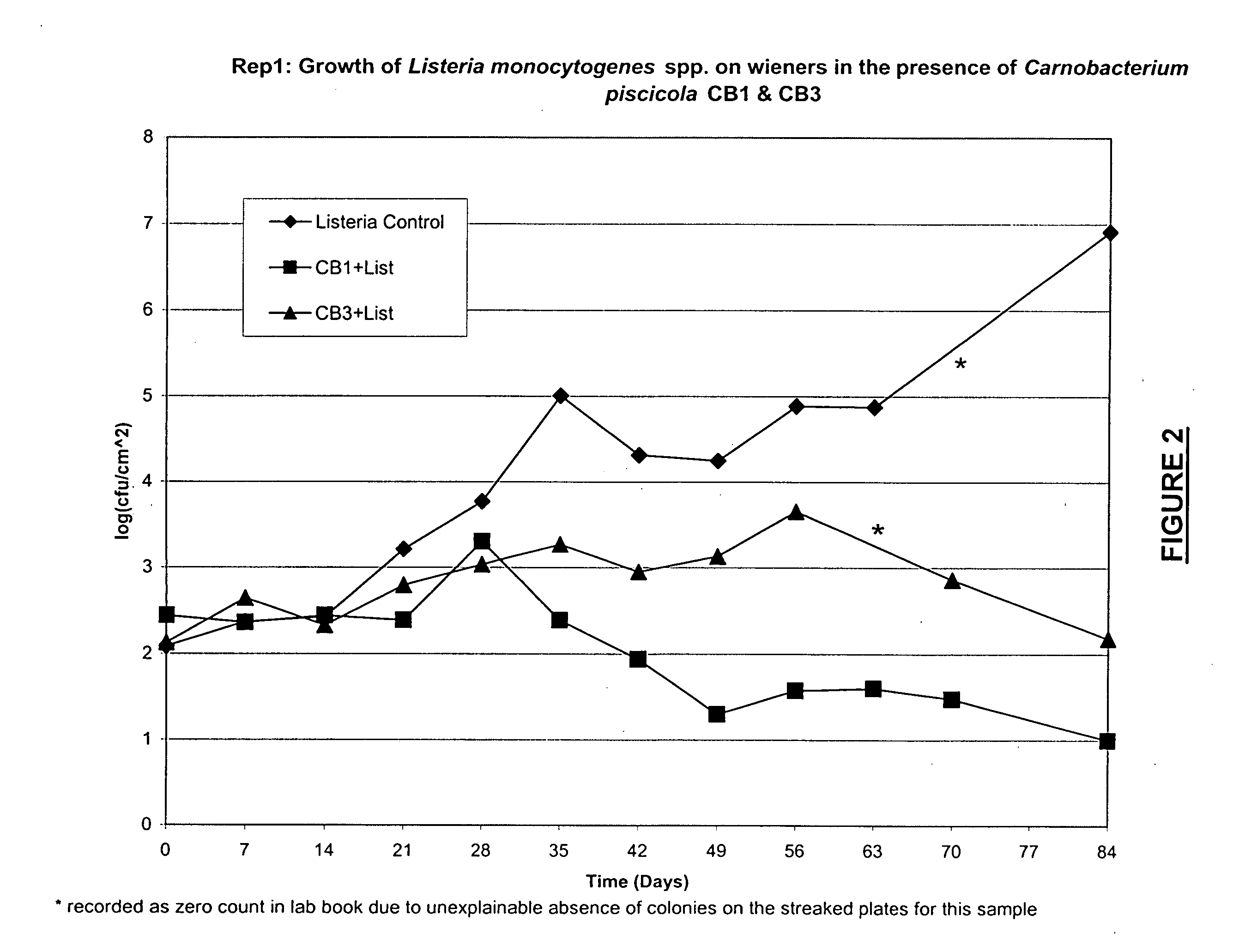

InactiveUS20050153033A1Unprecedented anti-listerial activityNot significant spoilageAnimal feeding stuffLeuconostocLactobacillusProcessed meat

The compositions and methods of the present invention involve the use of bacteria and / or their fermentate products to treat foods, such as fresh and processed meat products.

Owner:STILES MICHAEL E +2

Additive composition for shrimp feed and a method for producing the same

InactiveUS20150132436A1Increase survival and growth rateAvoid pollutionClimate change adaptationLactobacillusPuerariae radixDigestion

The present invention relates to an additive composition for shrimp feed and a method for producing the same, and more particularly to an additive composition for shrimp feed and a method for producing the same which both increases the survival and the growth rate of aquacultural shrimp and prevents seawater pollution. The present invention discloses a method for producing an additive composition for shrimp feed, which includes the steps of: mixing microorganisms such as saccharomyces, bacillus subtilis and lactobacillus, natural products such as red ginseng, tangle, agar, salicornia herbacea L, peucedanum japonicum thunberg, sea lettuce, dandelion, atractylodes chinensis, dropwort and Puerariae Radix, and fermented fruits such as apple, orange, mandarin, pineapple and melon; and extracting the ferment from the mixture, which provides an antiviral effect, increases immunity, improves digestion, promotes growth, decomposes remnant feed, etc.

Owner:J&B BIO

Seaweed ferment probiotic microcapsule and preparation method thereof

PendingCN111588038AImprove efficacyEnhance biological efficacyLactobacillusFood preservationBiotechnologyEcological environment

The invention provides a seaweed ferment probiotic microcapsule and a preparation method thereof. The microcapsule comprises a microcapsule wall, a microcapsule core material and a core material carrier, wherein the microcapsule wall is prepared from sodium alginate, chitosan and calcium chloride, the microcapsule core material is prepared from seaweed ferment and probiotic, and the core materialcarrier is corn starch. The seaweed ferment probiotic microcapsule of the invention can effectively block the influence of gastric acid and the like on the viable bacteria number and activity of the probiotic, so that the seaweed ferment and probiotic act on the intestinal micro-ecological environment together, and the unique biological effect is achieved. The preparation method is simple in process, is relatively low in cost, and is easy to store and transport. Compared with other probiotic products, the microcapsule has the advantages of good film-forming property, strong stability, high probiotic survival rate, good slow release efficiency and the like, is suitable for embedding and controllable release of various probiotics, and has good application prospects.

Owner:QINGDAO BRIGHT MOON SEAWEED BIO HEALTH TECH GRP CO LTD

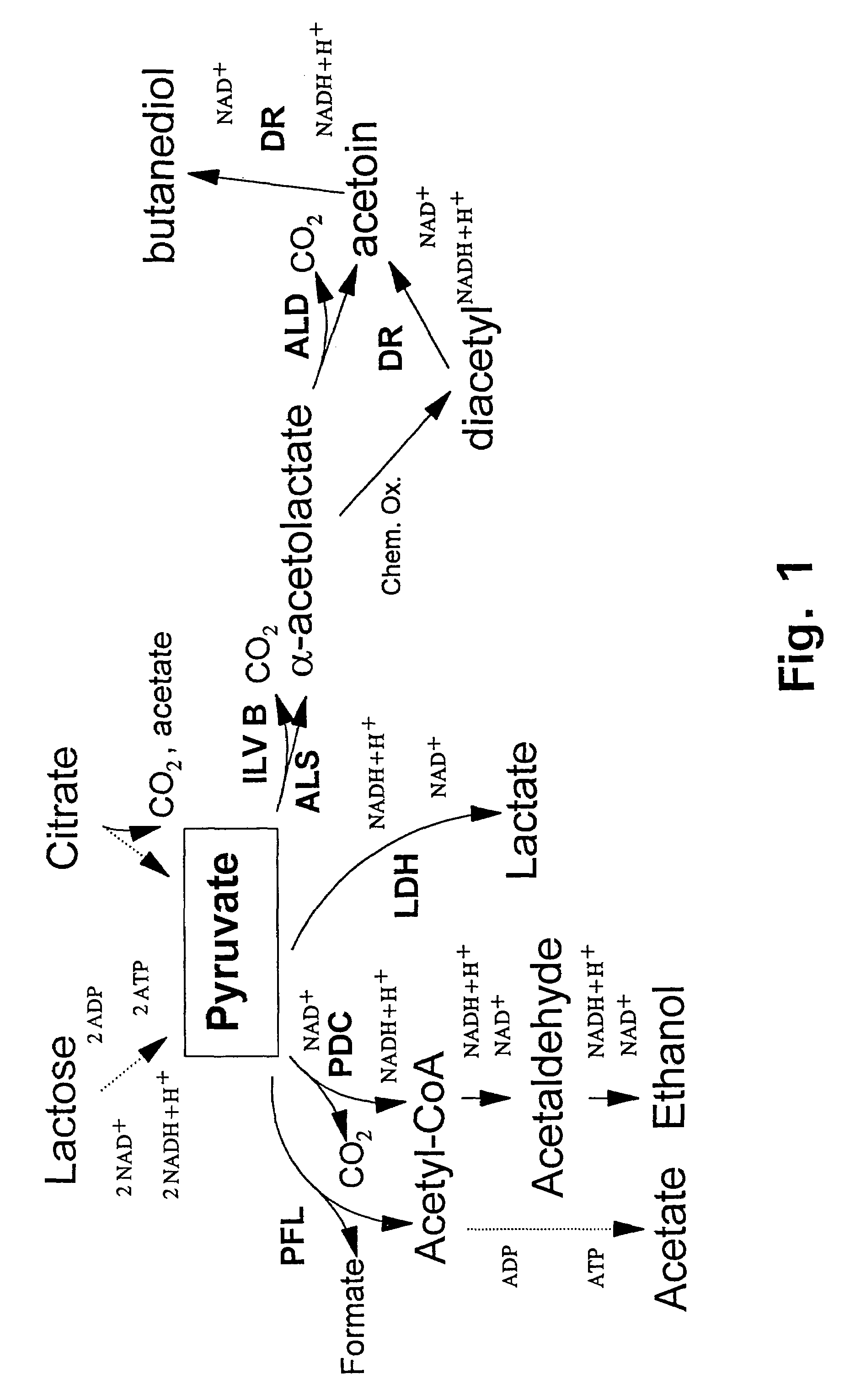

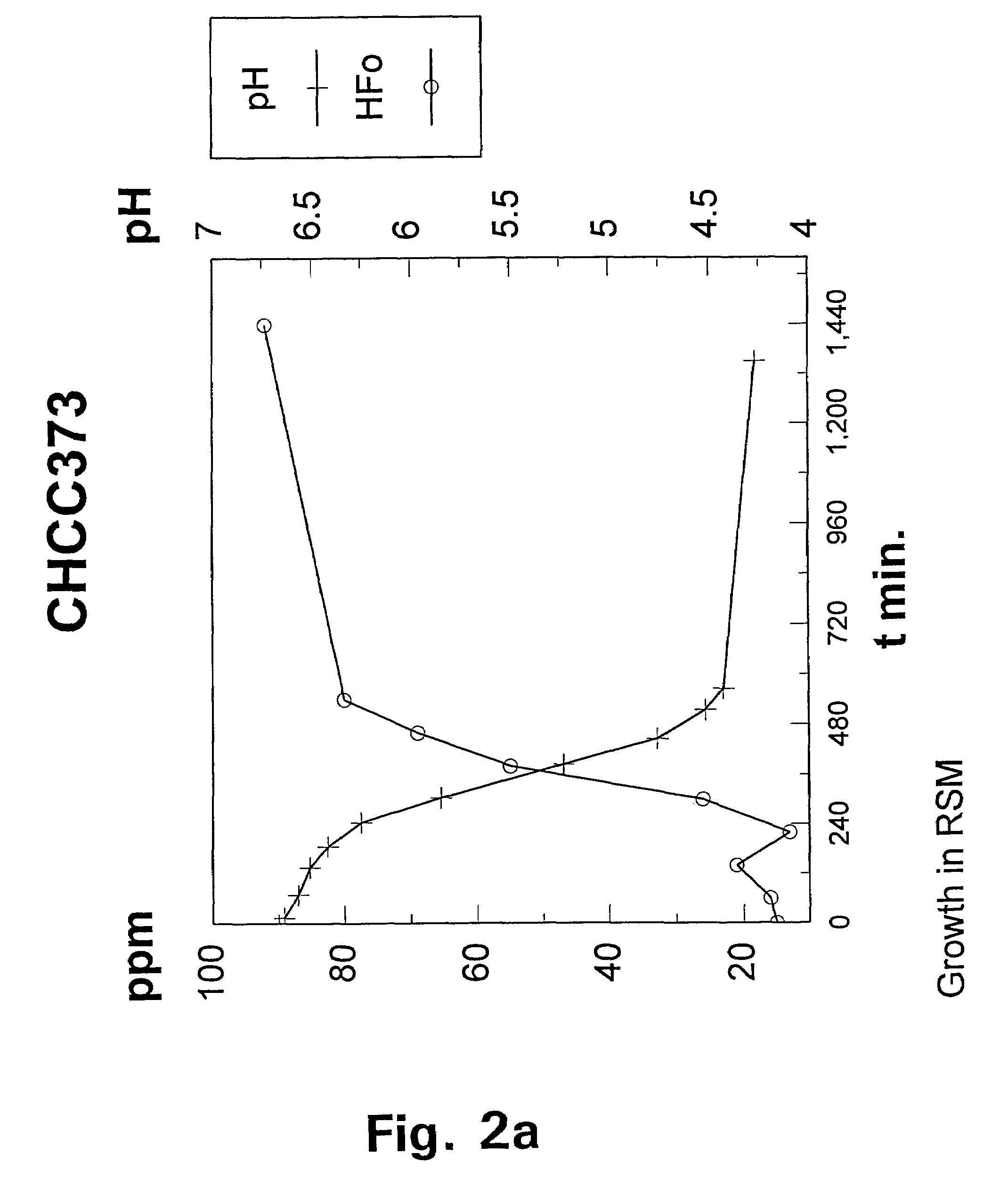

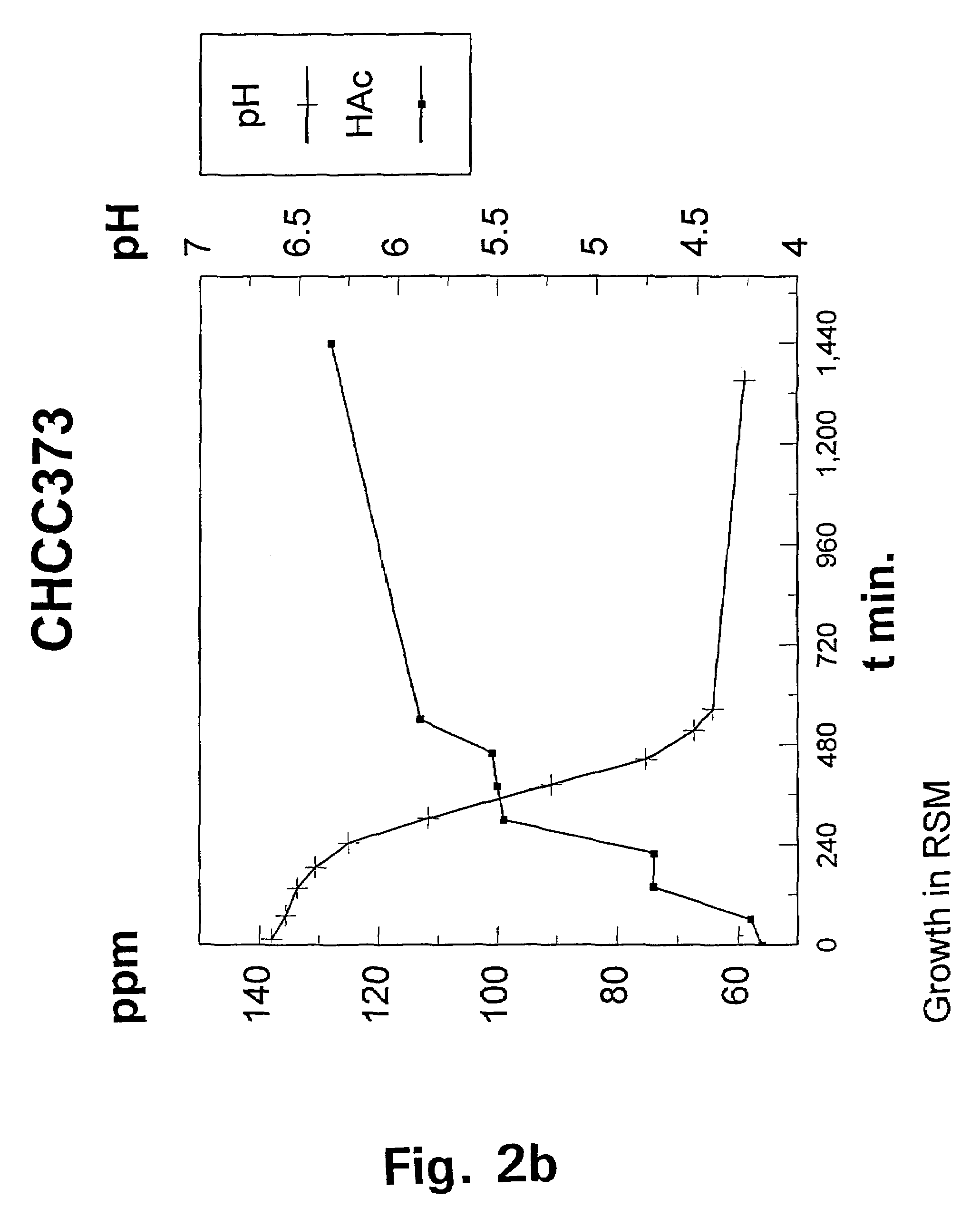

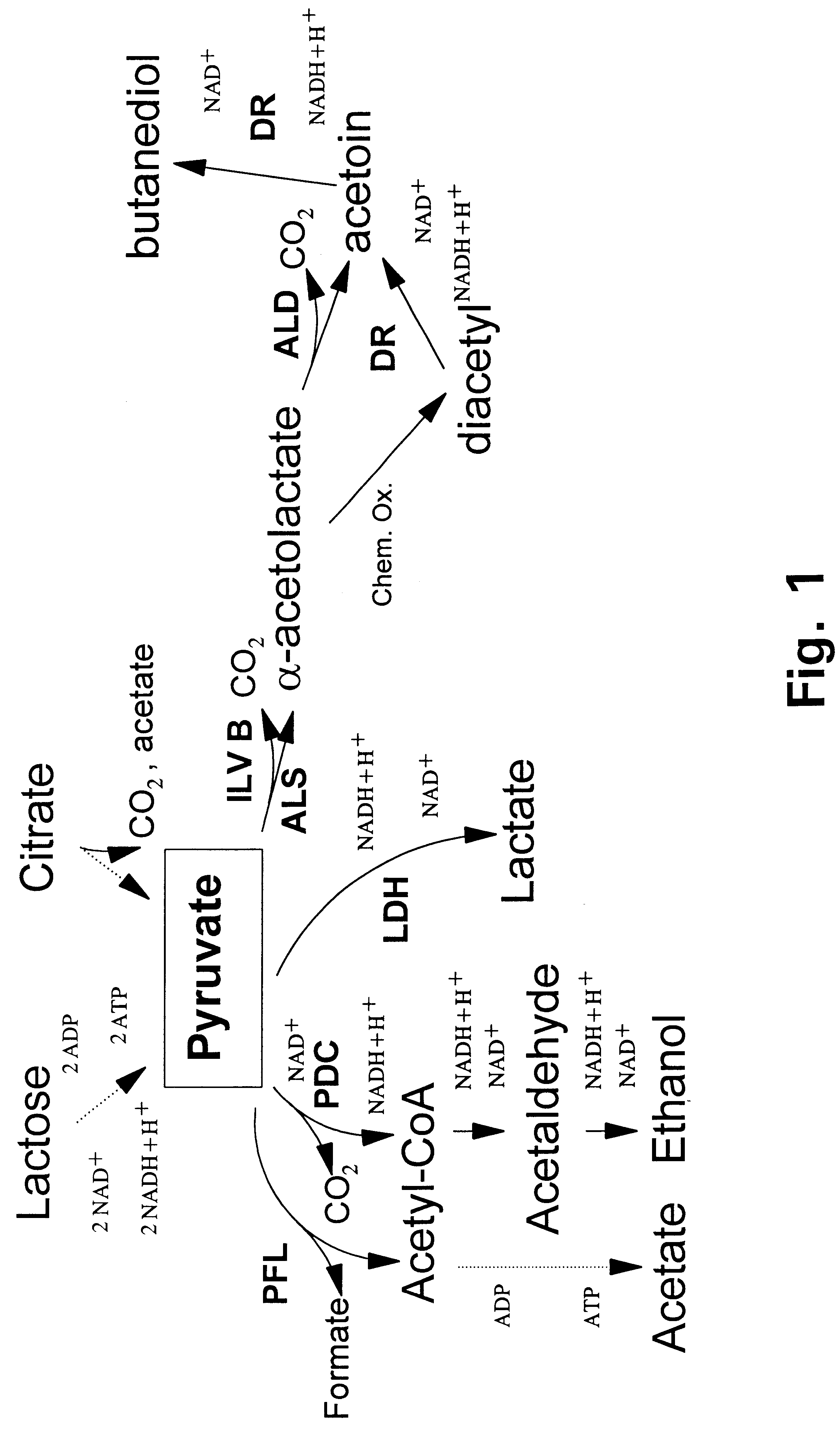

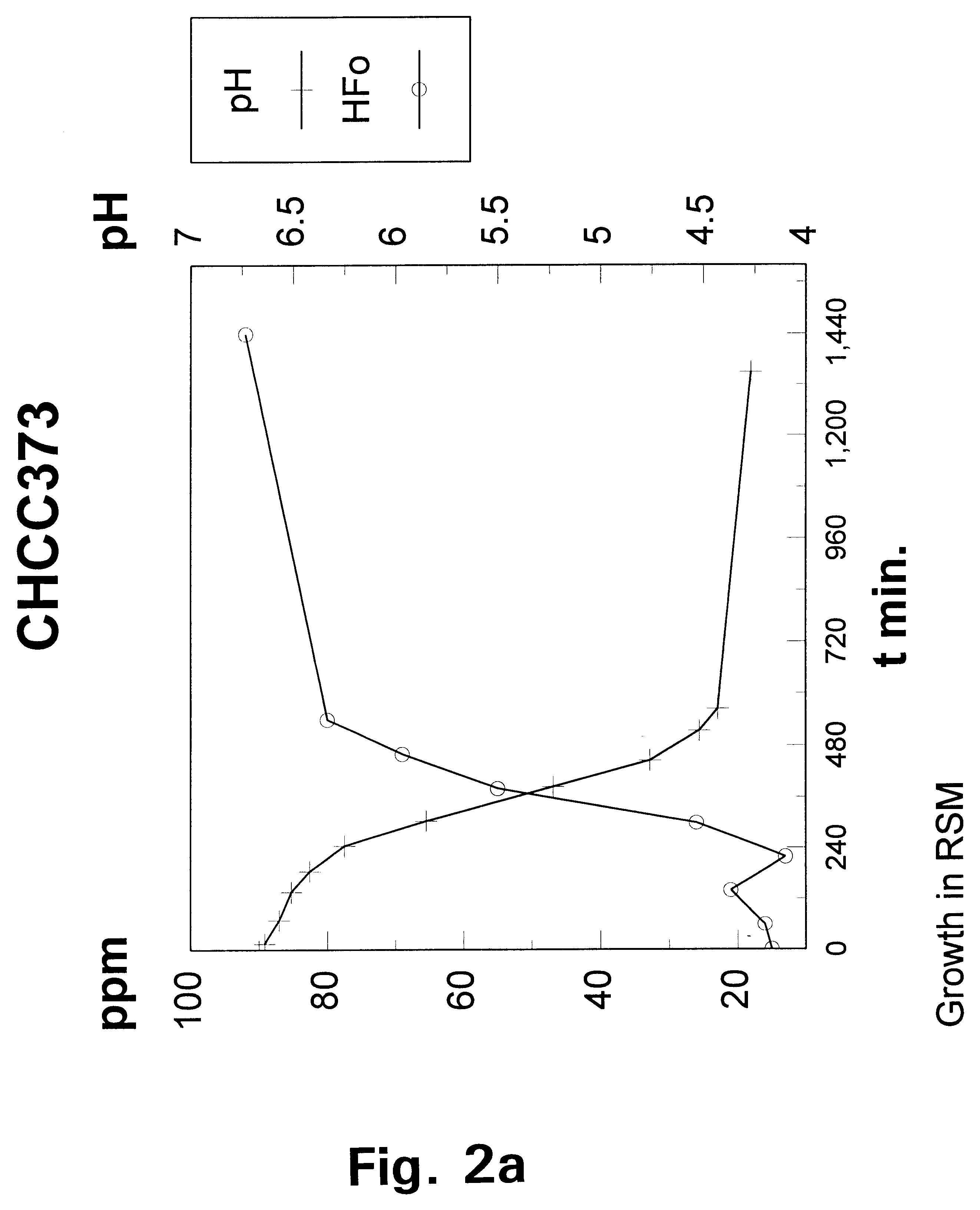

Metabolically engineered lactic acid bacteria and their use

InactiveUS7465575B2Reduced growth rateReduce probabilityBiocideBacteriaLactate dehydrogenaseLactic bacteria

Mutants of lactic acid bacteria including Lactococcus lactis which are defective in pyruvate formate-lyase production and / or in their lactate dehydrogenase (Ldh) production and methods of isolating such mutants or variants are provided. The mutants are useful in the production of food products or in the manufacturing of compounds such as diacetyl, acetoin and acetaldehyde and as components of food starter cultures.

Owner:NILSSON DAN

Coffee beans and fermentation method thereof

InactiveCN113439793AIncrease contact areaSpeed up the fermentation processLactobacillusLeuconostocBiotechnologySaccharomyces

The invention discloses coffee beans and a fermentation method thereof. The method comprises the following steps of: soaking peeled coffee berries in water, inoculating lactic acid bacteria, sealing with gauze, and performing anaerobic fermentation for 36-72 hours, wherein the pH value of the fermentation liquor at the fermentation end point is 3.35-4.00, thereby obtaining the coffee beans without a viscous liquid layer; and washing the obtained coffee beans with water, drying, shelling, and baking, thereby obtaining the finished product coffee beans, wherein the lactic acid bacteria consist of more than one of lactobacillus plantarum, leuconostoc mesenteroides or lactobacillus casei. According to the method disclosed by the invention, the lactic acid bacteria are inoculated for fermentation, the metabolic characteristics of the lactic acid bacteria are fully utilized, the coffee viscous liquid layer and nutrients of the bean bodies are utilized, the fermentation is performed in the liquid, anaerobic and acidic conditions suitable for growth of the lactic acid bacteria and saccharomycetes are created, the contact area between the strains and the bean bodies is increased, the fermentation process is accelerated, the coffee bean viscous liquid layer is effectively removed, the flavor precursor substance composition of the obtained raw beans is changed, and the final flavor quality of the coffee beans is improved.

Owner:SOUTH CHINA UNIV OF TECH

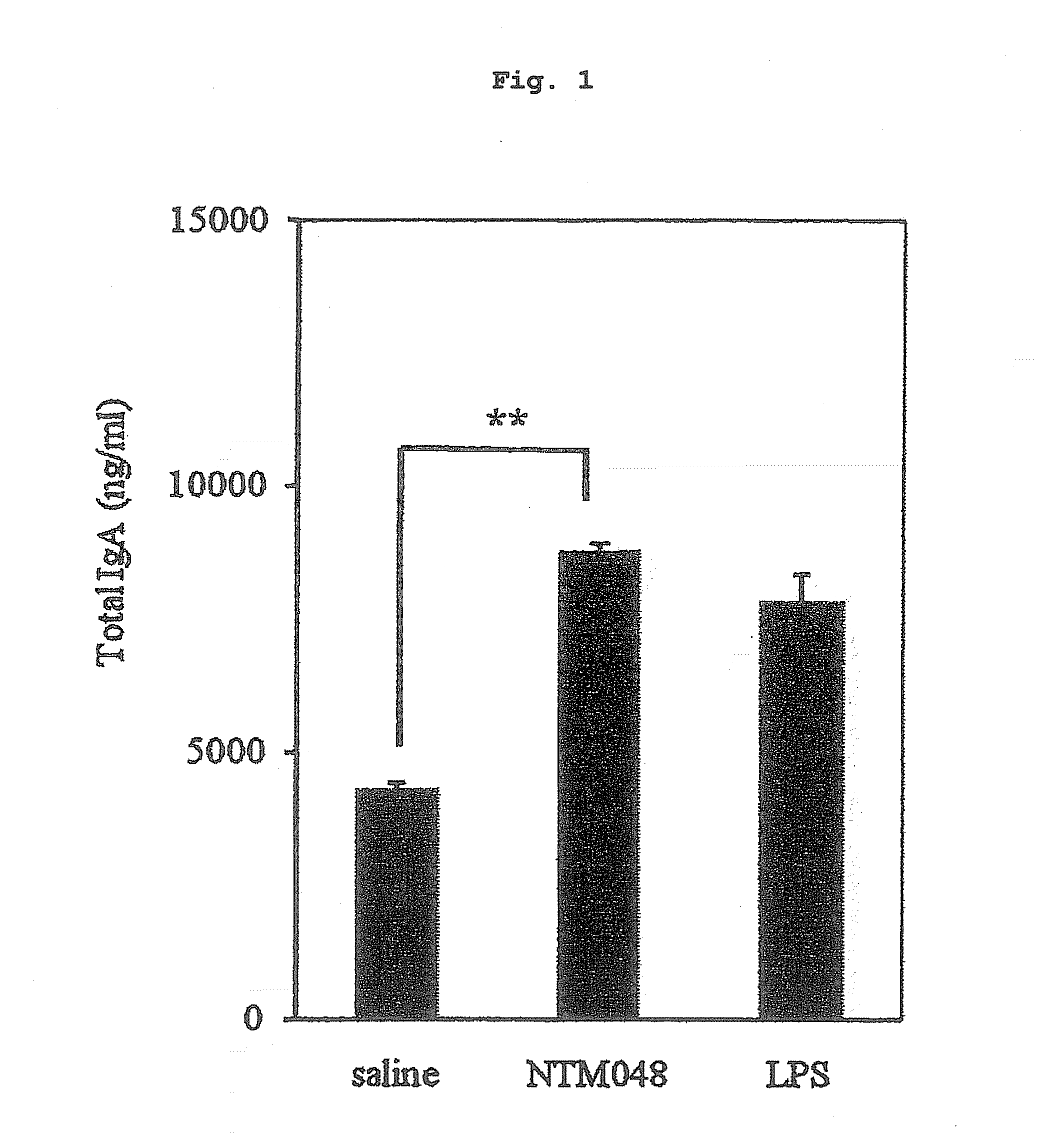

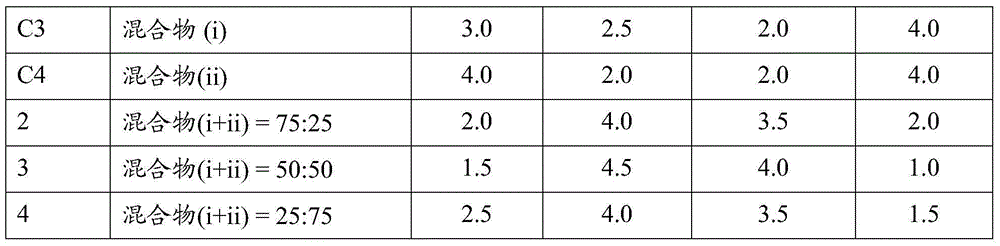

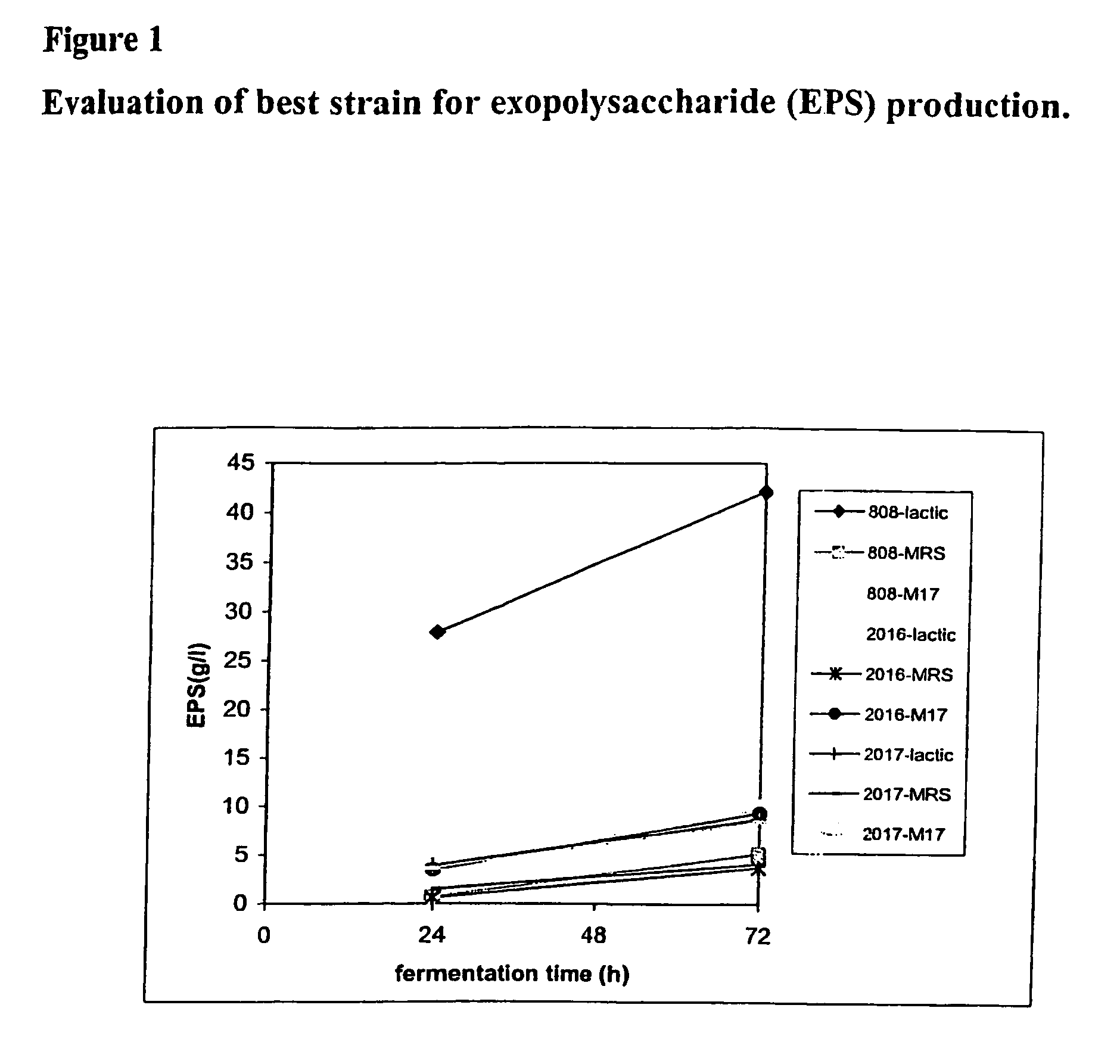

Exopolysaccharide produced by lactic acid bacterium

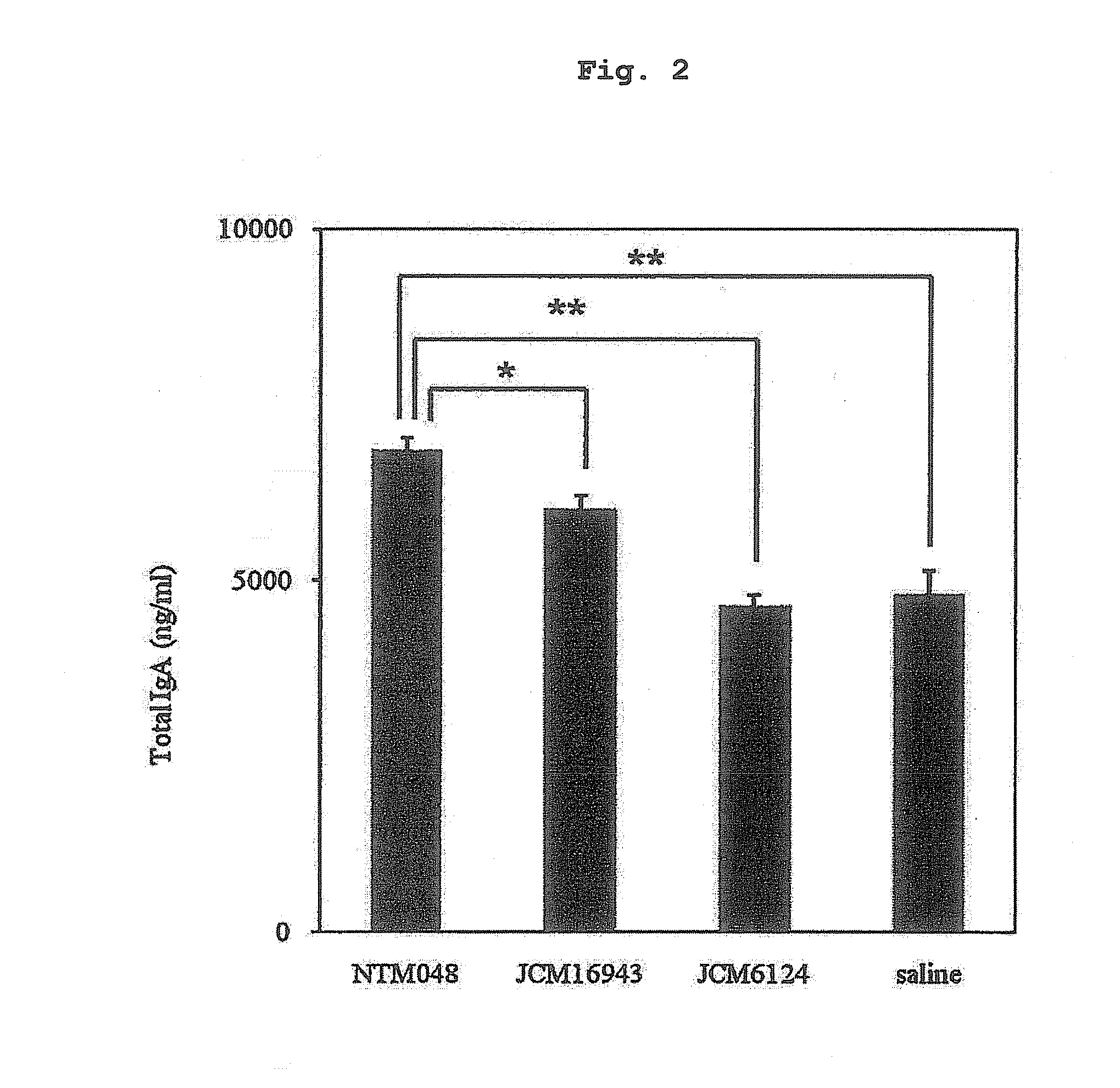

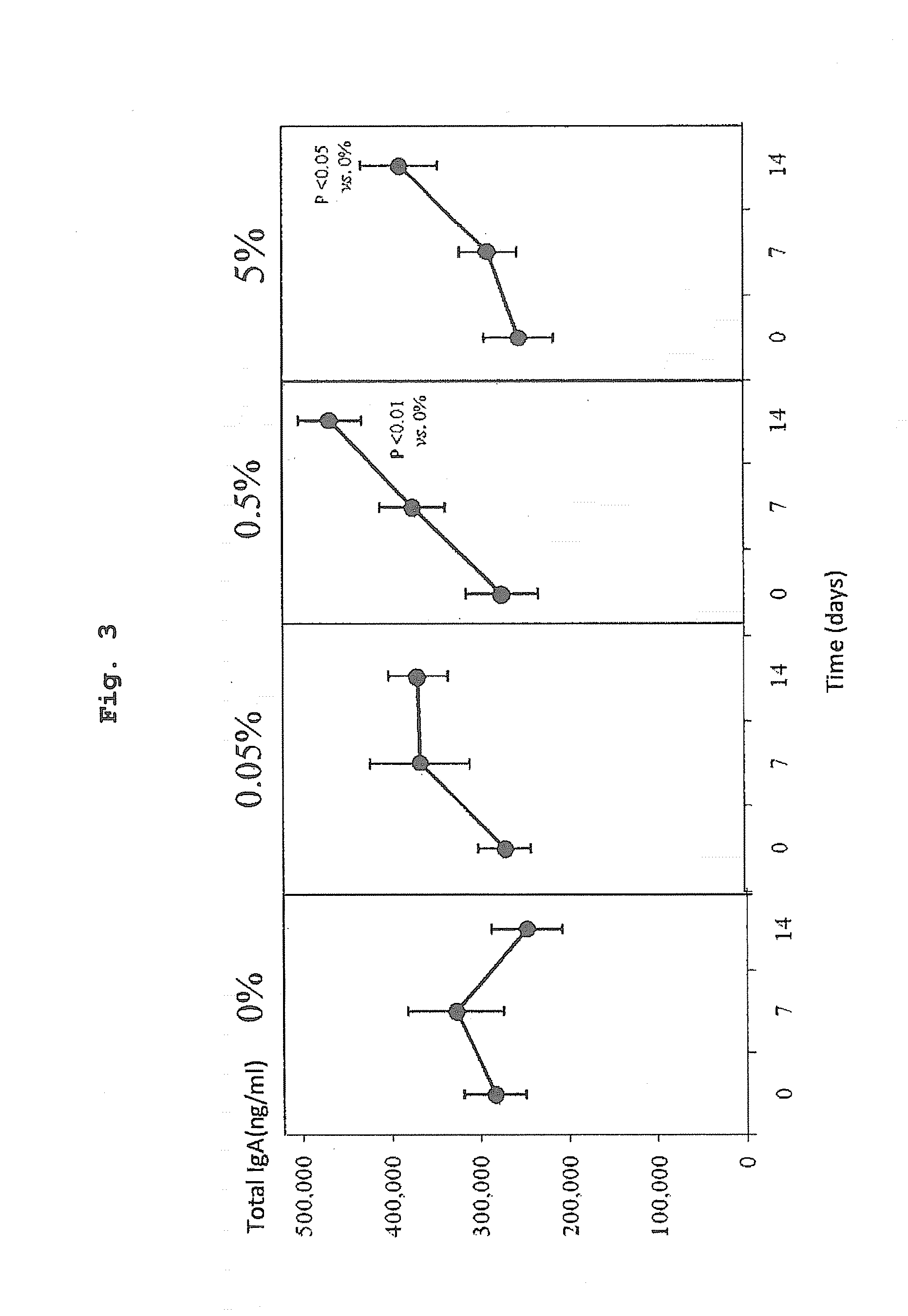

ActiveUS20160229925A1High IgA production promoting activityCosmetic preparationsOrganic active ingredientsLactic acid bacteriumPolysaccharide

Provided are exopolysaccharide produced by novel lactic acid bacteria having an IgA production promoting ability, a production method of the exopolysaccharide, a composition containing the exopolysaccharide, and the like.

Owner:NOSTER INC

Functional Fruits and Vegetables Bean Curd without Salt Water and Method for Preparing the Same

InactiveUS20120045547A1Lower digestibilityIncreased nutrient component componentLeuconostocOther dairy technologySaline waterMetabolite

Owner:KIM CHANG WHAN

Preparation method of selenium-enriched fermentation osmunda japonica thunb

ActiveCN103783421AGreat tasteKeep the colorLactobacillusLeuconostocNutritive valuesLactic acid fermentation

The invention discloses a preparation method of selenium-enriched fermentation osmunda japonica thunb. The preparation method is characterized in that fresh osmunda japonica thumb is used as the raw material and grafted with compound lactobacillus to ferment, wherein protease enhances the capacity of lactic acid bacteria on decomposing protein during the fermentation, and thus various amino acids which are easily combined with inorganic selenium can be produced, the inorganic selenium can be transformed into organic selenium, and as a result, the osmunda japonica thumb is rich in organic selenium. The selenium-enriched fermentation osmunda japonica thumb prepared by the method contains 34mg / kg of selenium to the maximum; the toxicity test shows that the selenium-enriched fermentation osmunda japonica thumb is safe and nontoxic, and the content is controllable; the added lactic acid bacteria improves the taste of fermented vegetable and removes the bitter taste of osmunda japonica thunb; in addition, the cold processing method of lactic acid fermentation is carried out, and sodium selenite having certain effect on resisting oxidation is added, so that the color, crispness and nutritional value of osmunda japonica thunb can be remained.

Owner:恩施硒圣植物科技有限公司

Method for Preparing Spoilage Resistant Raw Meat or Raw Seafood

InactiveUS20150272145A1Prevent spoilageSuppresses the outbreak of spoilageBacteriaUnicellular algaeBiotechnologyRaw meat

A method for preparing raw meat or raw seafood that is resistant to spoilage, comprising: a) incubating a solution comprising a population of non-pathogenic psychrotrophic lactic acid bacteria under conditions and for a period of time sufficient to enable growth of the bacterial population to form a bacterial culture capable of preventing spoilage; b) adding a saccharide to the bacterial culture and incubating the bacterial culture at a temperature of from 1 to 4° C., wherein the saccharide is present in an amount sufficient to achieve bacteriostasis of the bacterial culture; admixing the bacterial culture formed in step b) with the raw meat or raw seafood, wherein the bacteriostatic bacterial culture is present in an amount of from 1 to 20 weight % based on the total weight of the composition.

Owner:HILLS PET NUTRITION INC

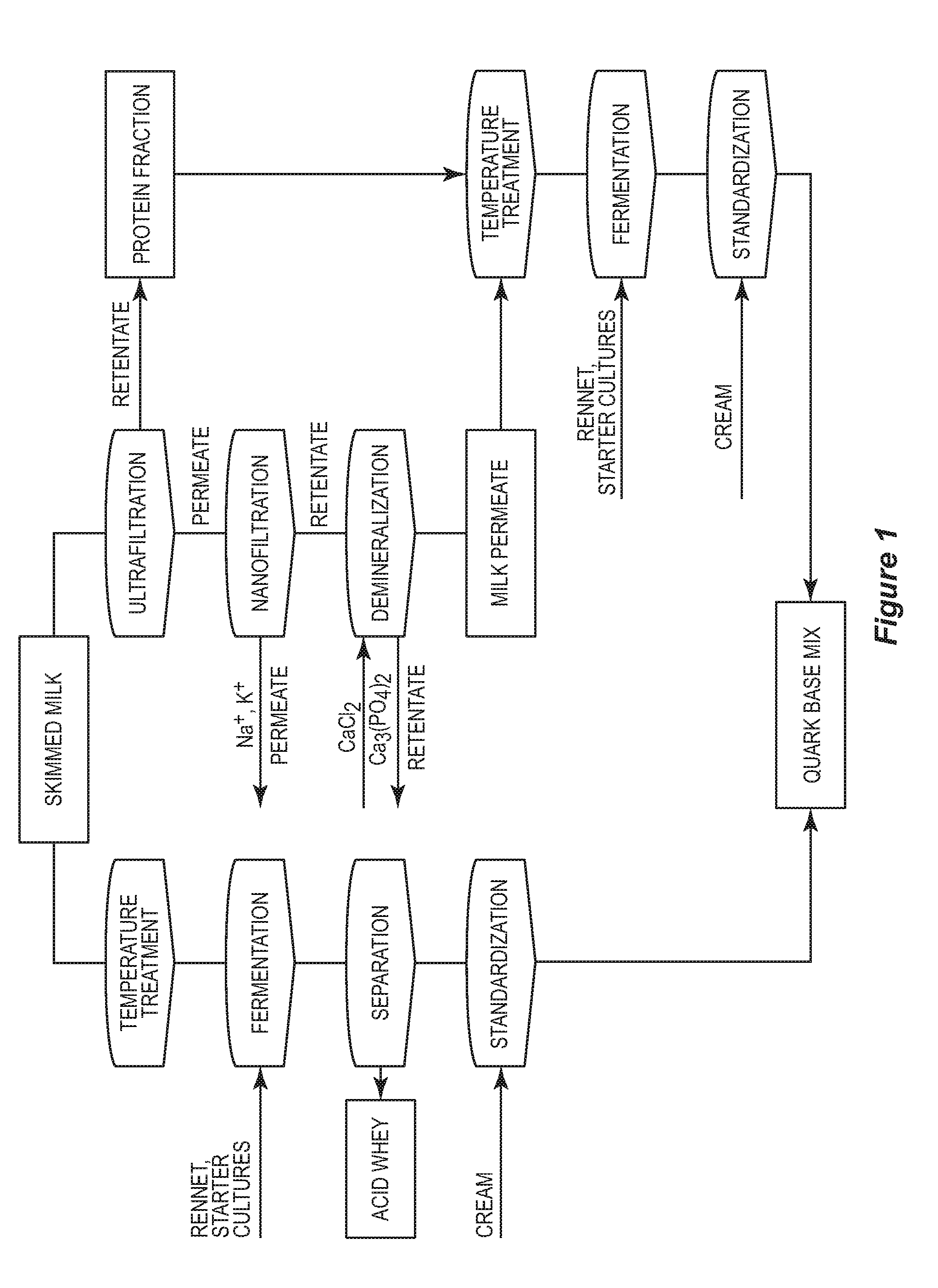

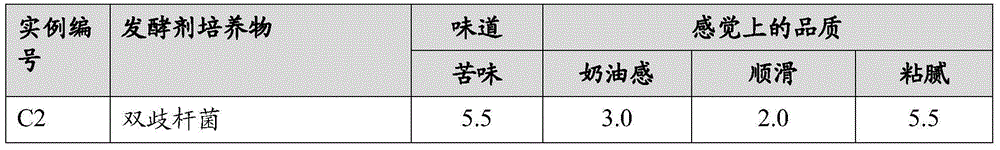

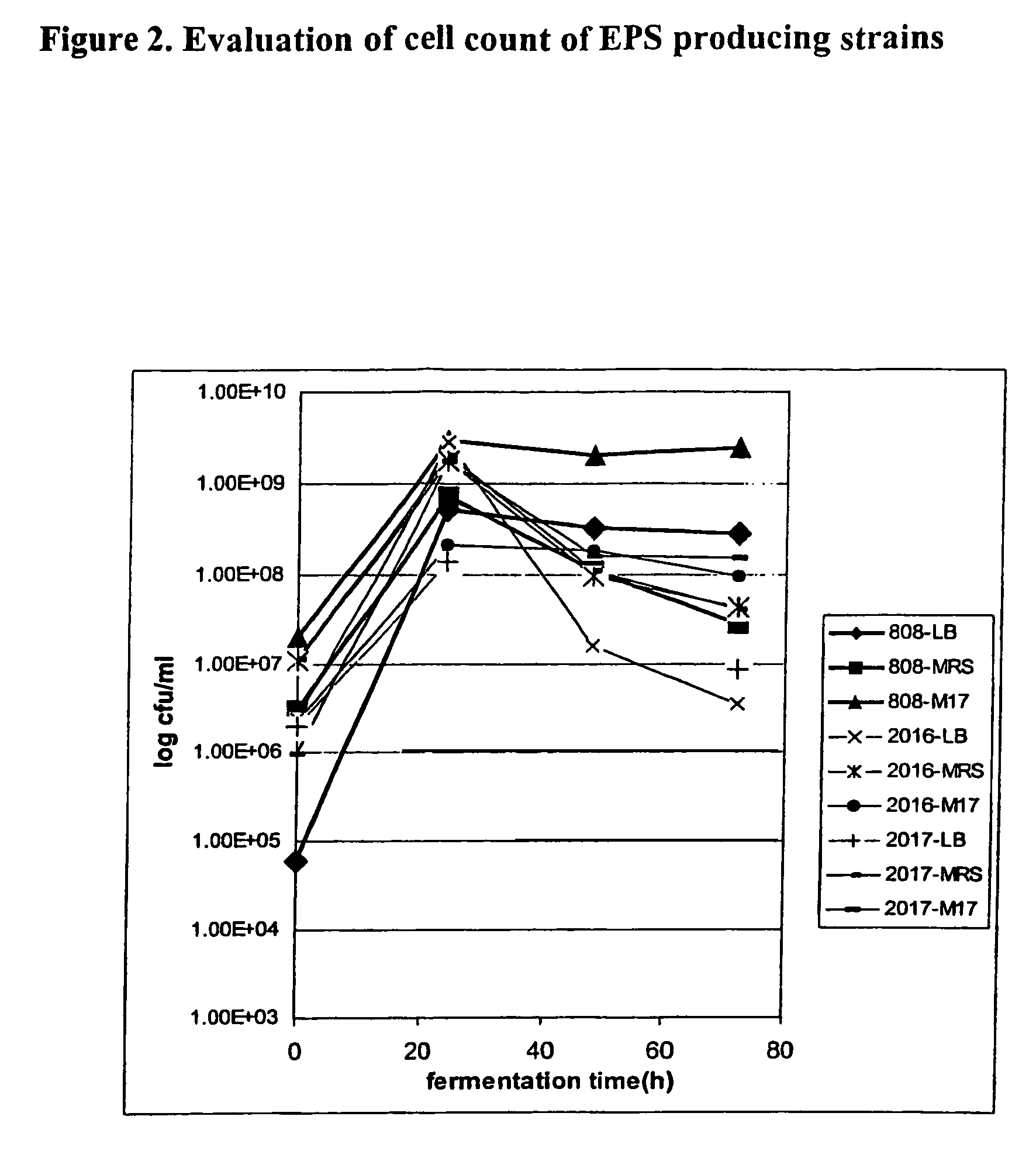

Quark base mix having enhanced taste properties iii

InactiveUS20150050386A1Great tasteUndesirable productMilk preparationStrepto/lacto-coccusStaphylococcus lactisPhosphate

A quark base mix is proposed having enhanced taste properties which is obtainable in that(a) raw milk is subjected to a temperature treatment and the cream is separated off,(b) the resultant skimmed milk is subjected to an ultrafiltration and in this case a first retentate R1 which contains a milk protein concentrate is produced, and a first permeate P1 is produced,(c) the first permeate P1 is subjected to a nanofiltration and / or reverse osmosis and in this case a second retentate R2 which contains alkali metal salts is produced, and a second permeate P2 is produced,(d) optionally the second retentate R2 is subjected to an alkaline demineralization and in this case a third retentate R3 which contains phosphate salts is produced and a third permeate P3 is produced,(e) the third permeate P3 is combined with the retentate R1 in such a manner that a non-acidified quark base mix is formed, and(f) the resultant mixture is subjected to a temperature treatment until denaturation occurs, and finally(g) the denatured product is admixed with starter cultures and rennet and optionally(h) the quark base mix thus obtained after completion of fermentation is adjusted to a defined dry matter content and protein content,and in step (g), as starter culture(i) a first mixture of five microorganisms comprising (i-1) Streptococcus thermophilus, (i-2) Leuconostoc species, (i-3) Lactococcus lactis subsp. lactis biovar diacetylactis, (i-4) Lactococcus lactis subsp. lactis and (i-5) Lactococcus lactis subsp. cremoris, and(ii) a second mixture of three microorganisms comprising (ii-1) Streptococcus thermophilus, (ii-2) Lactococcus lactis subsp. lactis and (ii-3) Lactococcus lactis subsp. cremoris is used.

Owner:DMK DEUT MILCHKONTOR

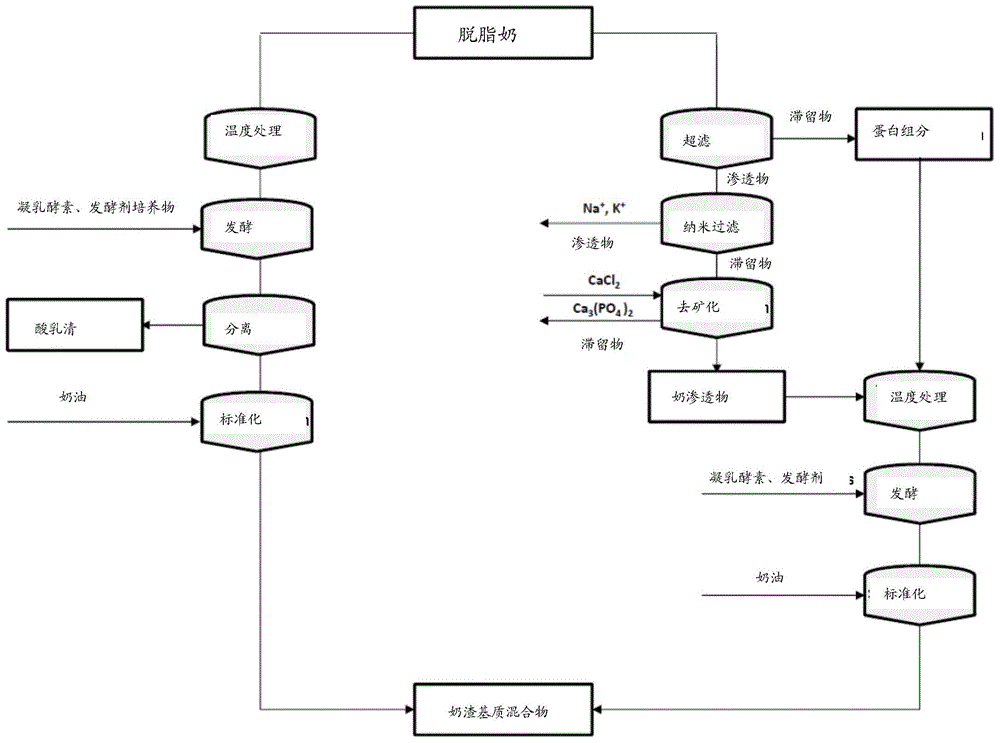

Quark base mix having enhanced taste properties

InactiveCN104365865AReduce generationMilk preparationStrepto/lacto-coccusStaphylococcus lactisUltrafiltration

A quark base mix is proposed having enhanced taste properties which is obtainable in that (a) raw milk is subjected to a temperature treatment and the cream is separated off, (b) the resultant skimmed milk is subjected to an ultrafiltration and in this case a first retentate R1 which contains a milk protein concentrate is produced, and a first permeate P1 is produced, (c) the first permeate P1 is subjected to a nanofiltration and / or reverse osmosis and in this case a second retentate R2 which contains alkali metal salts is produced, and a second permeate P2 is produced, (d) optionally the second retentate R2 is subjected to an alkaline demineralization and in this case a third retentate R3 which contains phosphate salts is produced and a third permeate P3 is produced, (e) the third permeate P3 is combined with the retentate R1 in such a manner that a non-acidified quark base mix is formed, and (f) the resultant mixture is subjected to a temperature treatment until denaturation occurs, and finally (g) the denatured product is admixed with starter cultures and rennet and optionally (h) the quark base mix thus obtained after completion of fermentation is adjusted to a defined dry matter content and protein content, and in step (g), as starter culture (i) a first mixture of five microorganisms comprising (i-1) Streptococcus thermophilus, (i-2) Leuconostoc species, (i-3) Lactococcus lactis subsp. lactis biovar diacetylactis, (i-4) Lactococcus lactis subsp. lactis and (i-5) Lactococcus lactis subsp. cremoris, and (ii) a second mixture of three microorganisms comprising (ii-1) Streptococcus thermophilus, (ii-2) Lactococcus lactis subsp. lactis and (ii-3) Lactococcus lactis subsp. cremoris is used.

Owner:DMK DEUT MILCHKONTOR

Composition

The present invention relates to a composition and a method of preparing or treating food products so as to improve their aroma, flavor, mildness, sweetness, consistency, texture, body, mouth feel, firmness, viscosity, gel fracture, wheying off, structure and / or organoleptic properties, nutrition and / or health benefits. In particular, the present invention provides a composition comprising a live micro-organism, an enzyme produced by said micro-organism and an exopolysaccharide (EPS) produced by the activity of said enzyme.

Owner:DUPONT NUTRITION BIOSCIENCES APS

A probiotic composition comprising at least two lactic acid bacterial strains which are able to colonise the gastrointestinal tracts in combination with having intestinal survival property, intestinal

In a probiotic composition comprising at least two specific lactic acid bacterial strains, the strains are able to colonize the gastrointestinal tract of humans and animals and have in combination at least two beneficial properties. The properties include an intestinal survival property, an intestinal binding property, an infection protecting property, and a fiber fermenting property.

Owner:生物合成公司

Greek-flavored fermented milk made through MPC liquid and preparation method of Greek-flavored fermented milk

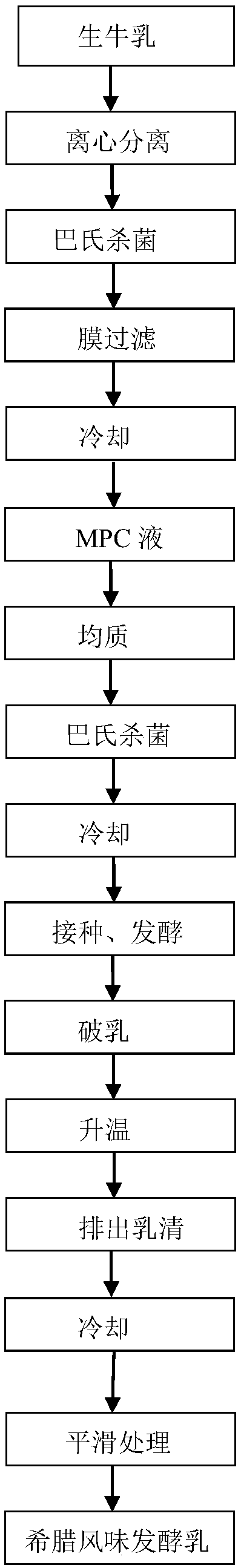

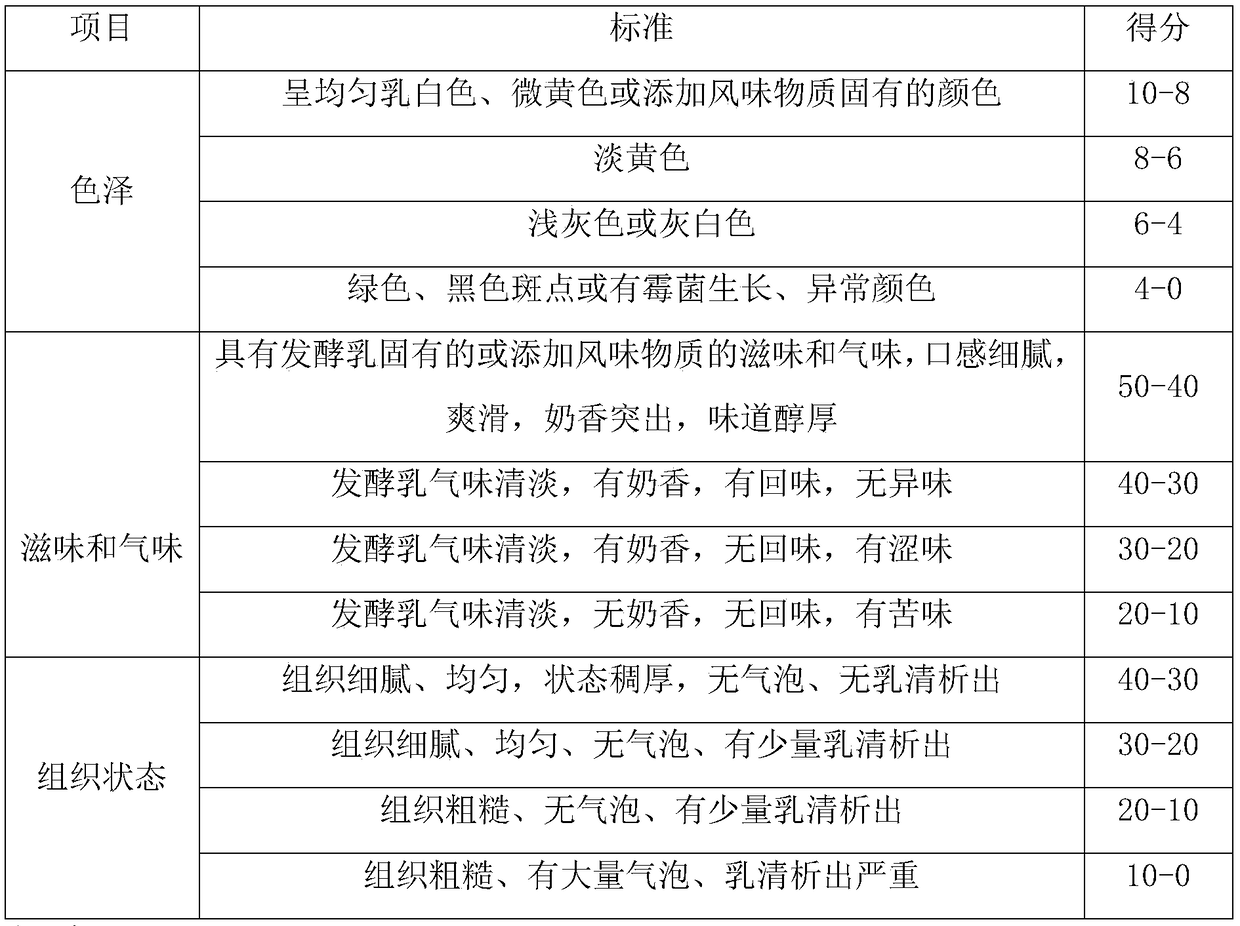

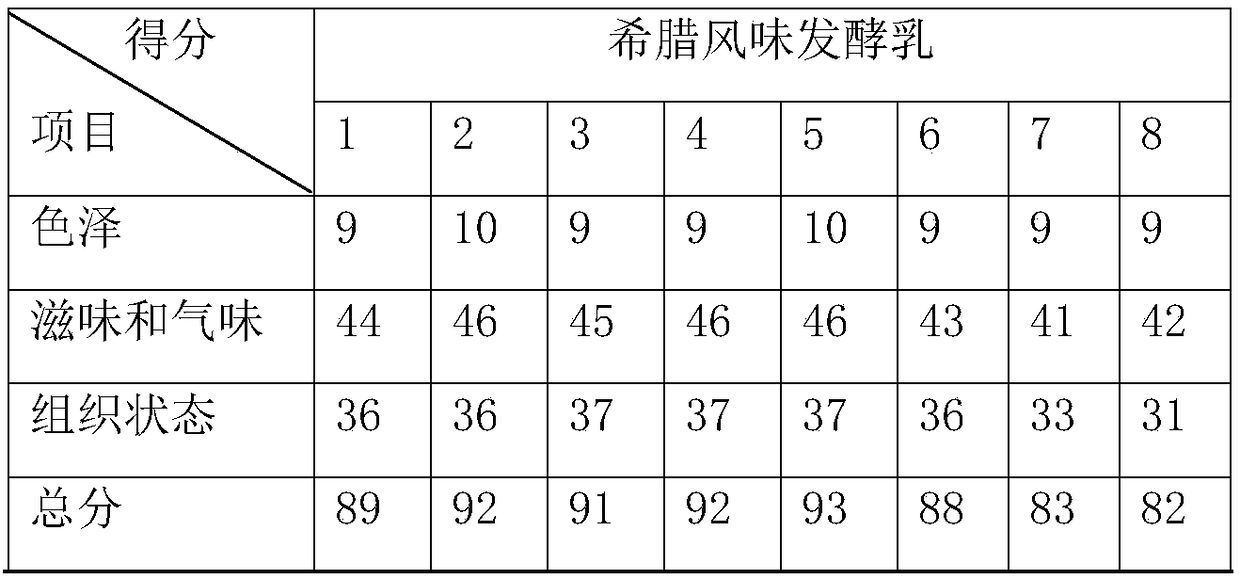

InactiveCN108606063AFat content controlEmission reductionMilk preparationLactobacillusTotal solid contentFiltration membrane

The invention belongs to the field of deep processing of dairy products, and particularly relates to a method for making Greek-flavored fermented milk through concentrated milk protein liquid and theGreek-flavored fermented milk. The making method comprises the main steps of preheating raw milk to 55-65 DEG C, performing centrifugal separation to enable the fat content in skimmed milk to be smaller than or equal to 0.1%, or performing standardization to enable the fat content of standardized milk to be smaller than or equal to 1.4%; then performing pasteurization at 72-95 DEG C for 15-30 seconds; then performing filtration through an ultra filtration membrane to obtain trapped fluid namely MPC liquid, wherein the protein content is 5.0-7.0%, the fat content is smaller than or equal to 3.5%, and the total solid content is greater than or equal to 11.0%; performing homogenizing on the MPC liquid, performing pasteurization, performing temperature reduction, performing inoculation with strains, performing fermentation until pH value is 4.4-4.7 to obtain a fermented milk base material, and performing demulsification; after demulsification, raising the temperature of materials to 45-55DEG C, and draining sour milk serum of which the mass percentage is 20-50% of that of the fermented milk base material; and performing smooth processing so as to obtain the Greek-flavored fermented milk.

Owner:宁夏塞尚乳业有限公司

Making method of raspberry enzyme beverage

InactiveCN105707627AFull of nutritionSignificantly regulate immune functionLeuconostocYeast food ingredientsNutrientChemistry

The invention discloses a making method of an enzyme beverage with raspberry as the raw material, belongs to the field of food, and relates to a making method of a fruit enzyme beverage, in particular to a raspberry enzyme beverage and a making method thereof. The method for making raspberry enzymes by inoculating Hanseniaspora valbyensis, Debaryomyces hansenii, Leuconostoc oenos and acetic bacteria with raspberry as the raw material is provided for the current situation that raspberry is rich in nutrient and has a remarkable immunity adjusting function, a radiation damage prevention function, an oxidation resistant function, a memory improving function, a cancer, tumor and ageing resistant function and other functions but is difficult to store. By means of the method, the additional value of agricultural products can be easily improved, the new species of raspberry products can be developed, and the species and variety of enzyme are increased, and good application prospects are achieved.

Owner:河北长益生物科技有限公司

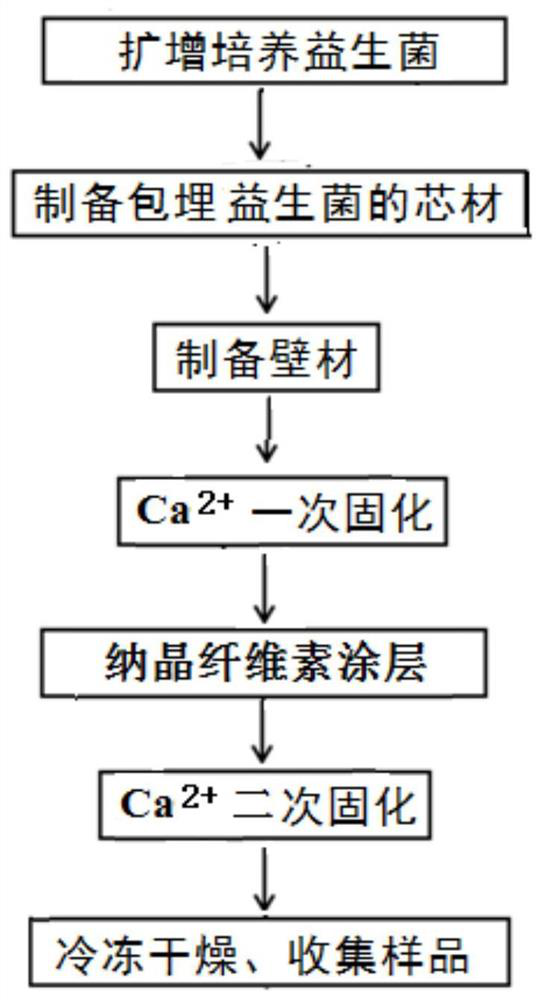

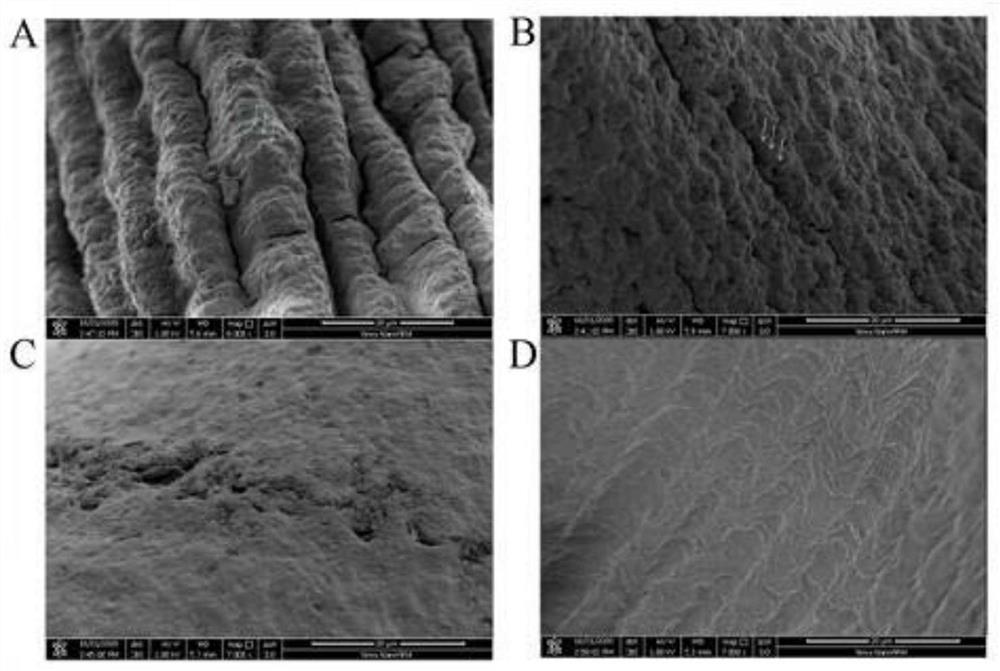

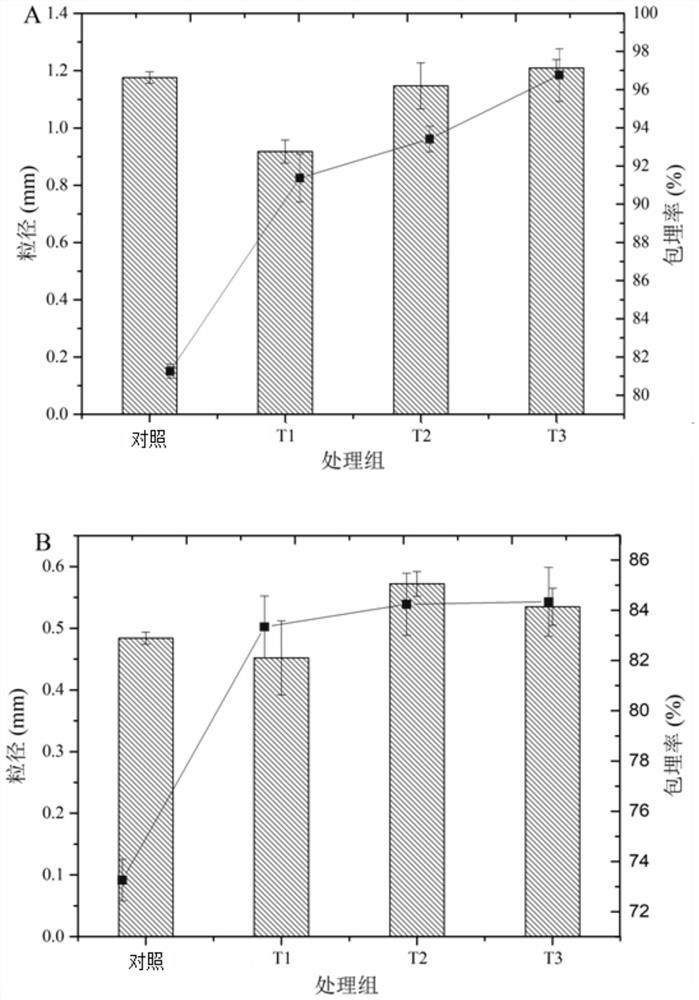

Microcapsule-embedded probiotics capable of being released at fixed points in intestinal tracts and preparation method thereof

PendingCN112544978AImprove acid barrierGood oxygen barrier effectFood freezingLactobacillusBiotechnologyCellulose

The invention discloses microcapsule-embedded probiotics capable of being released at fixed points in intestinal tracts and a preparation method thereof. The preparation method comprises the followingsteps: preparing probiotics subjected to expansion culture into a W / O type core material, coating a wall material composed of whey protein and sodium alginate, and sequentially carrying out Ca<2+> primary curing, nanocrystalline cellulose coating and Ca<2+> secondary curing. The microcapsule embedded with the probiotics is good in enteric solubility, and the activity of the probiotics can still reach about 10<6> CFU / g after simulated gastrointestinal digestion.

Owner:上海扬彩生物科技有限公司

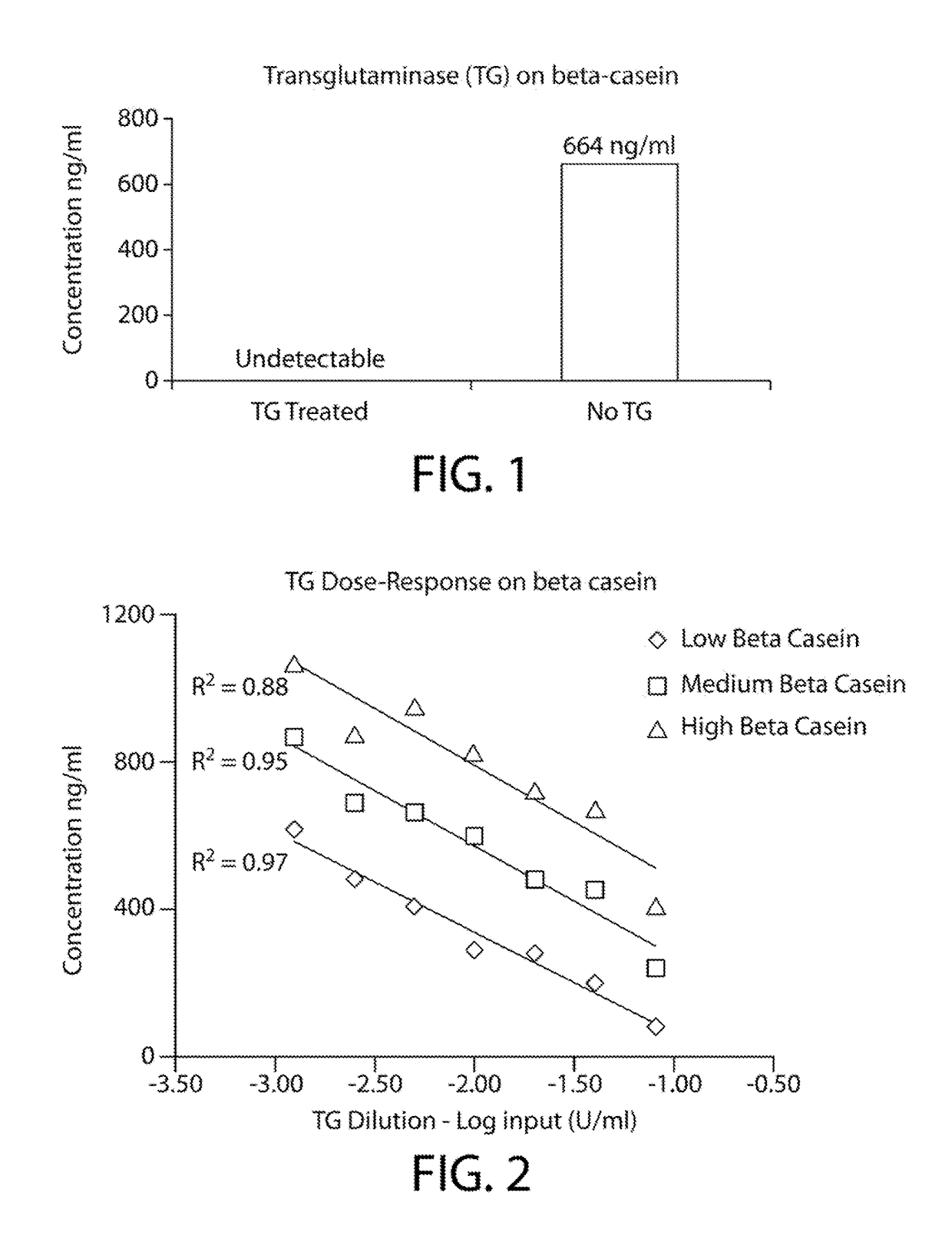

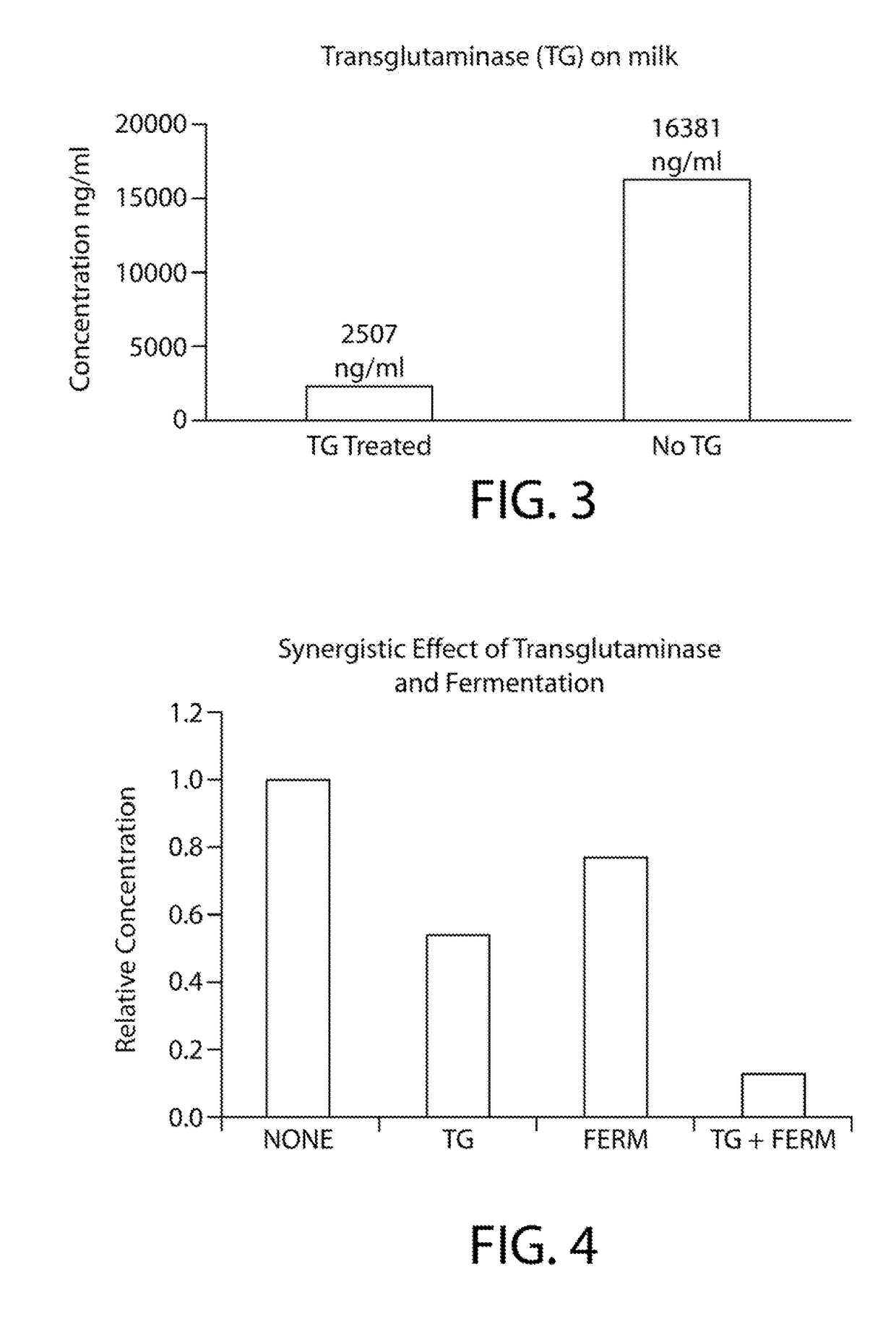

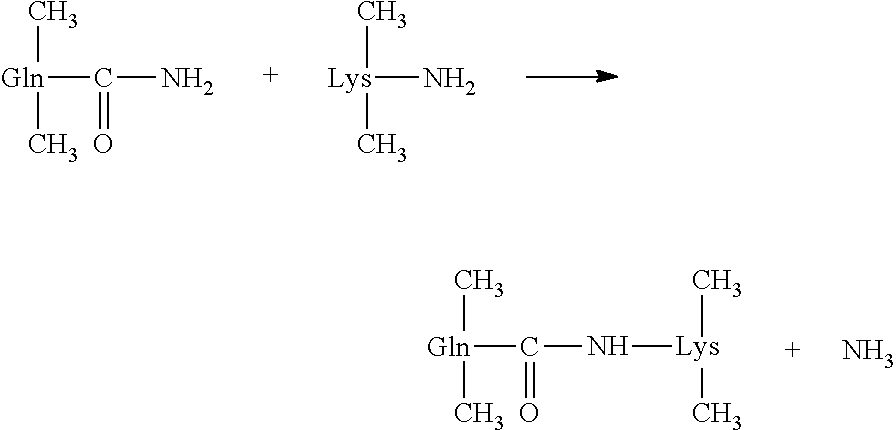

Method and Compositions for Reducing Immunorecognition of Dietary Protein

The present disclosure is directed to a method for reducing immunoreactivity of a food including (a) incubating a food that contains at least one protein with a cross-linking enzyme to form a food that includes at least one cross-linked protein; and (b) fermenting the food including the at least one cross-linked protein with a microorganism to form a modified food including a hydrolysate of the at least one cross-linked protein, wherein (a) is performed before (b) and wherein a level of immunoreactivity of the modified food is less than a level of immunoreactivity of an unmodified food including at least one protein. Modified foods obtained from the present method are also provided.

Owner:HILLS PET NUTRITION INC

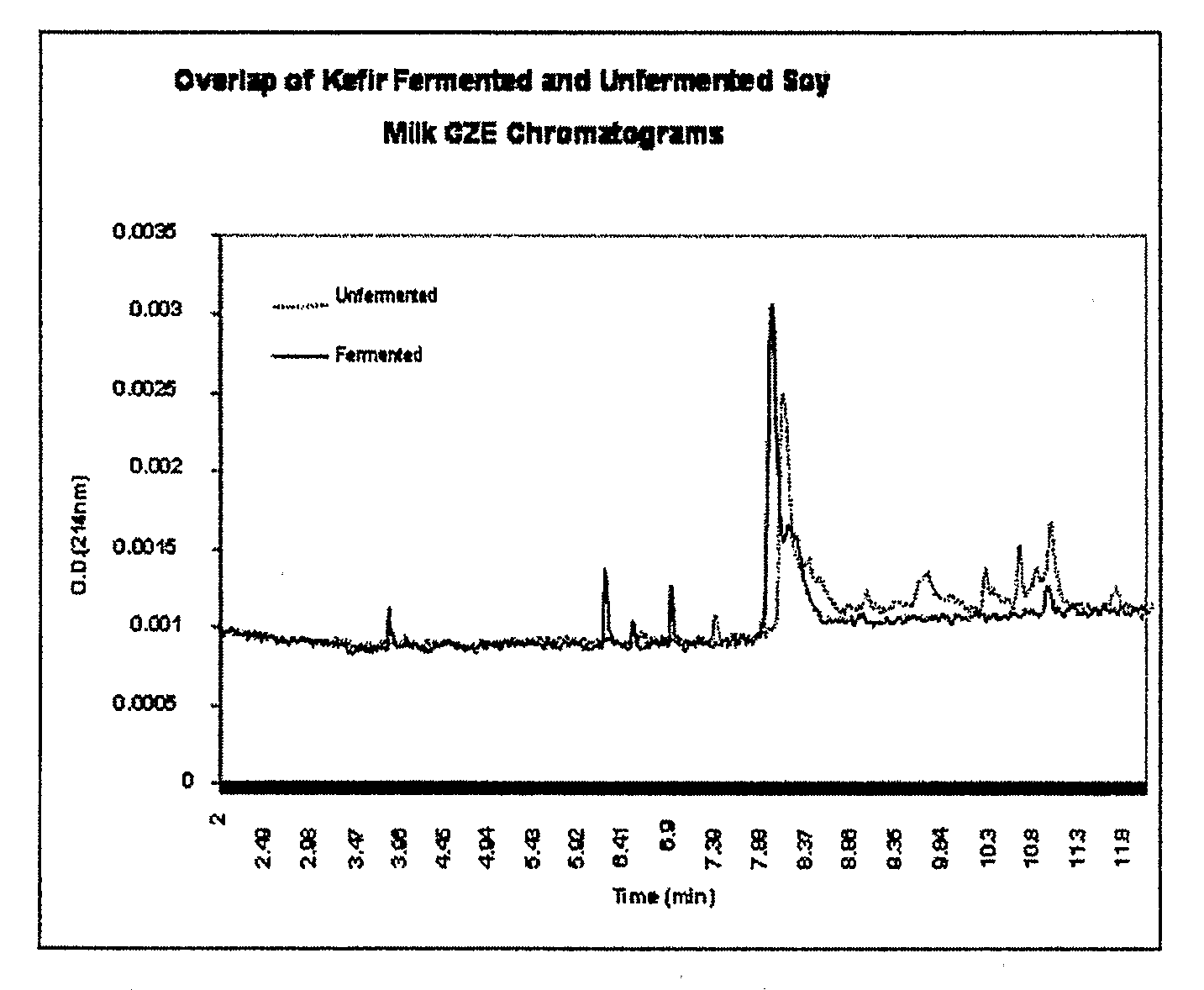

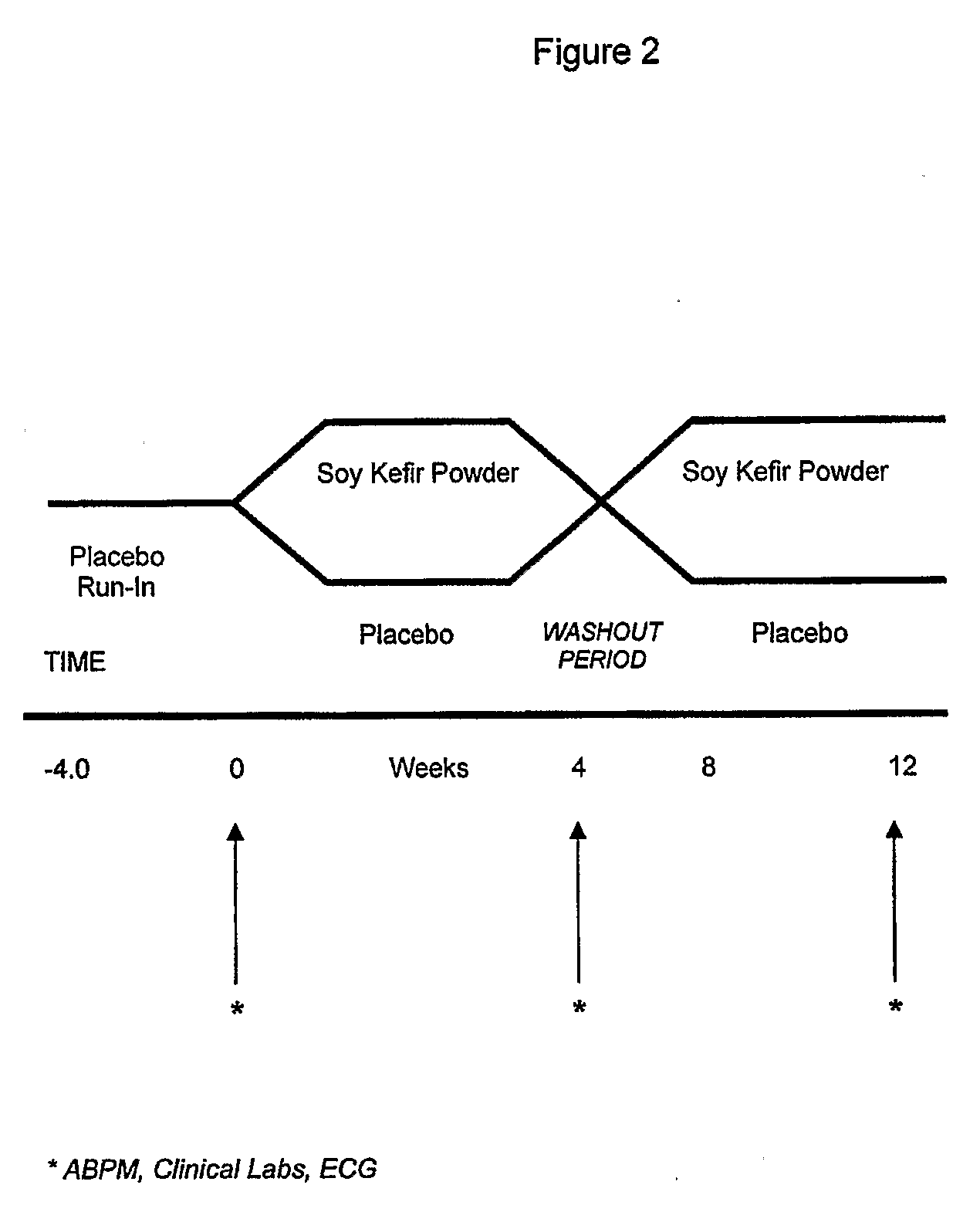

Use of soy kefir powder for reducing pain, blood pressure and inflammation

InactiveUS20090221469A1Improve effectivenessImproved isoflavone profileBiocideNervous disorderMedicineBlood pressure

The present invention relates to a soy kefir powder produced by the fermentation of soy milk with Kefir grains of the Moscow strain under suitable fermentation conditions. The soy kefir powder of the invention has at least one of the following biological activities: pain relief, blood pressure reduction and inflammation reduction. The present invention also relates to the method of production of the soy kefir powder of the invention. It also relates to the use of the soy kefir powder of the invention for pain relief, blood pressure reduction and inflammation reduction. The invention also relates to methods for pain relief, blood pressure reduction and inflammation reduction by using the soy kefir powder of the invention.

Owner:KCLM RES & NUTRITION

Low-nitrite-content jar changing pickled vegetables and preparing method thereof

The invention relates to the technical field of food processing, in particular to low-nitrite-content jar changing pickled vegetables and a preparing method thereof. The method includes the steps that 1, a blank is prepared, wherein fresh vegetables are collected, cleaned, subjected to fixation, cut into pieces, dewatered and batched; 2, the vegetables are put into a traditional clay jar and compressed, the top face of the blank is covered with leaf mustard, palm leaves are put in, and bamboo battens are used for compressing; 3, when pickled to be sweet and sour, the vegetables are taken out of the jar, packaged in a big bag in vacuum and refrigerated at the temperature of 10-15 DEG C; 4, the vegetables are stir-fried with an iron pan or a cast iron pan; 5, when the vegetables are stir-fried, a certain quantity of auxiliary material is added and stirred uniformly; 6, the vegetables obtained after stir-frying and material mixing are packaged in vacuum and sterilized with microwaves to obtain the finished product. The product obtain through the preparing method of the jar changing pickled vegetables is low in nitrite content or even free of nitrite and long in shelf life and has unique flavor.

Owner:ZHANGJIAJIE LINGJIE ORGANIC FOOD

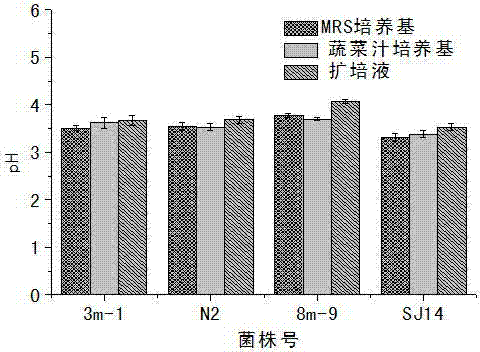

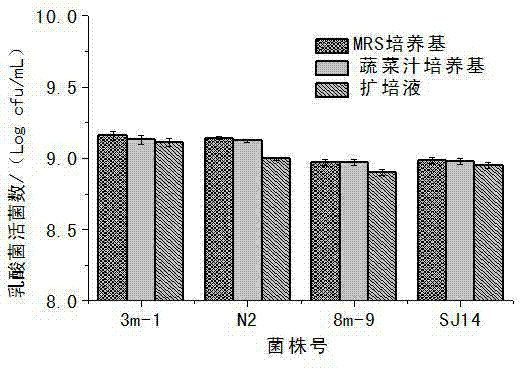

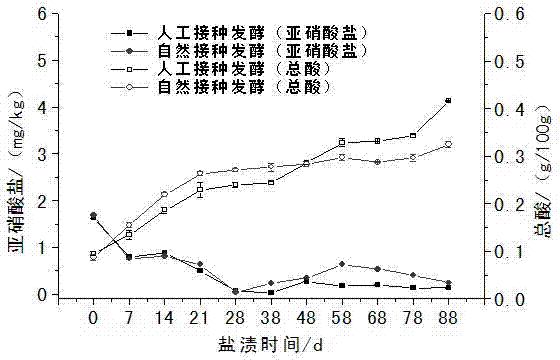

Lactobacillus propagation solution preparation method and inoculant preparation method in industrial salted vegetable production

InactiveCN104498414AReduce manufacturing costLow costBacteriaClimate change adaptationSucroseSaccharum

The invention discloses a lactobacillus propagation solution preparation method and an inoculant preparation method in industrial salted vegetable production. The propagation solution preparation method comprises the steps that one litre of salting liquid (the amount of salting liquid is amplified in proportion according to production needs) is collected from a vegetable salting and fermenting vat (the vegetable salting time ranges from two days to five days), the salting liquid is in appropriate standing so that large-particle sediment can be removed, a liquid matrix with the volume ranging from 800 mL to 900 mL is obtained, 1% to 4% (w / v) of any one of glucose, lactose and sucrose is added and dissolved, and the mixture is boiled for 10 min to 40 min, and cooled to 30 DEG C to serve as the lactobacillus propagation solution. The inoculant preparation method comprises the steps that cultures are activated, the inoculated propagation solution is subjected to first-level culture propagation in level-by-level culture propagation, the inoculated propagation solution is subjected to second-level culture propagation in level-by-level culture propagation and the inoculated propagation solution is subjected to third-level culture propagation in level-by-level culture propagation. By the adoption of the methods, the four cultures of lactobacillus are propagated into liquid inoculants, the viable counts of the liquid inoculants are all larger than 108 cfu / mL, the inoculants are mixed in proportion and added into the vegetable salting vat for collaborative fermentation, compared with natural fermentation, the acid production speed is higher, fermented vegetable products are more crisp and tender in quality and lower in nitrate content, and the viable count of lactobacillus is larger. The methods are low in production cost, easy to operate and high in practicability.

Owner:SICHUAN AGRI UNIV

Deproteinized and dephosphorized nutritional steamed sponge cake suitable for patients suffering from kidney diseases and processing method of steamed sponge cake

InactiveCN106071766ANutritious recipesImprove the quality of lifeYeast food ingredientsLactobacillusDiseaseLife quality

The invention discloses a processing method of a deproteinized and dephosphorized nutritional steamed sponge cake suitable for patients suffering from kidney diseases. According to the method, 60-90 parts of deproteinized and dephosphorized rice flour by weight, 0-10 parts of fish protein powder by weight, 0-10 parts of whey protein powder by weight, 5-20 parts of dietary fiber by weight, 1-10 parts of vegetable powder by weight, 0-5 parts of plant oil by weight, 3-10 parts of white granulated sugar by weight, 0.5-8 parts of a leavening agent by weight and 50-150 parts of water by weight are taken and evenly mixed, the mixture is placed into a fermentation box for fermentation treatment, is placed into a proofing box for proofing after fermentation and is placed into a steam cabinet for steaming, and the deproteinized and dephosphorized nutritional steamed sponge cake is obtained. The prepared steamed sponge cake has rich nutrition, has certain functions and is suitable for patients suffering from chronic kidney diseases. The product enriches the nutritious diet of the patients suffering from kidney diseases, improves the living quality of the patients, delays development of kidney diseases and has great significance for the patients suffering from kidney diseases.

Owner:武汉好多多生物科技有限公司

Lactobacillus fermentation accelerant for fermenting fruit and vegetable juice, and application thereof

InactiveCN106858261APromote fermentationFermented lactic acid bacteria fermentation promotionSugar food ingredientsLactobacillusFood borneFreeze-drying

The invention provides a lactobacillus fermentation accelerant for fermenting fruit and vegetable juice. The lactobacillus fermentation accelerant comprises nutrient substances and compound lactobacillus. The nutrient substances are prepared from 1 to 5 parts of food-borne functional peptide, 5 to 8 parts of glucose, 3 to 5 parts of lactose, 1 to 2 parts of sodium dihydrogen phosphate, and 1 to 2 parts of sodium citrate. The compound lactobacillus are prepared from 5 to 10 parts of lactobacillus freeze-dried powder, 30 to 50 parts of crystal fructose, and 15 to 50 parts of prebiotics. Compared with the prior art, the lactobacillus fermentation accelerant has the advantages that the nutrient substances are added according to nutritional requirements for fermentation and growth of lactobacillus, and the lactobacillus adopts a single-layer and multi-layer mixed embedding manner, which more contributes to promotion of lactobacillus fermentation; meanwhile, the nutrient substances and the compound lactobacillus are added into the fruit and vegetable juice in accordance with a ratio of (1 to 2):1, thereby shortening the fermentation period of the fruit and vegetable juice, increasing the fermentation speed of the fruit and vegetable juice, and avoiding the probability of contaminating microorganism pollution; the growth of the lactobacillus is accelerated, the growth of other contaminating microorganisms is inhibited, and the health risk is reduced; the flavor and taste of the fruit and vegetable juice are improved, so as to make the fruit and vegetable juice taste rich and delicious.

Owner:HEILONGJIANG JOHNSUN BIOLOGICAL ENG CO LTD

Pickled compound fermented flavored meat product and processing method thereof

InactiveCN106942623AReduce pungent smellIncrease the fragranceMeat/fish preservation by heatingLactobacillusFlavorNitrite

The present invention discloses a pickled compound fermented flavored meat product and a processing method thereof. The compound fermented flavored meat product is prepared from pickling vegetables as an accessory raw material, low-salt and low-nitrite pickled meat blocks are stewed using bone soup, the stewed meat blocks are oil-fried using an oil and water mixture, an artificially intensified inoculation compound fermentation technology is used, the pickled vegetables and meat blocks are subjected to the mixed packaging fermentation, and then after a storage treatment, the meat product is subjected to a matched vacuum packaging at a certain ratio, and the packaged meat product is subjected to an atmospheric pressure heat sterilization to prepare the finished products. The method shortens the production cycle of the fermented meat product and the produced fermented meat product is high in safety, good in flavor, long in shelf life and easy for consumption.

Owner:CHENGDU UNIV

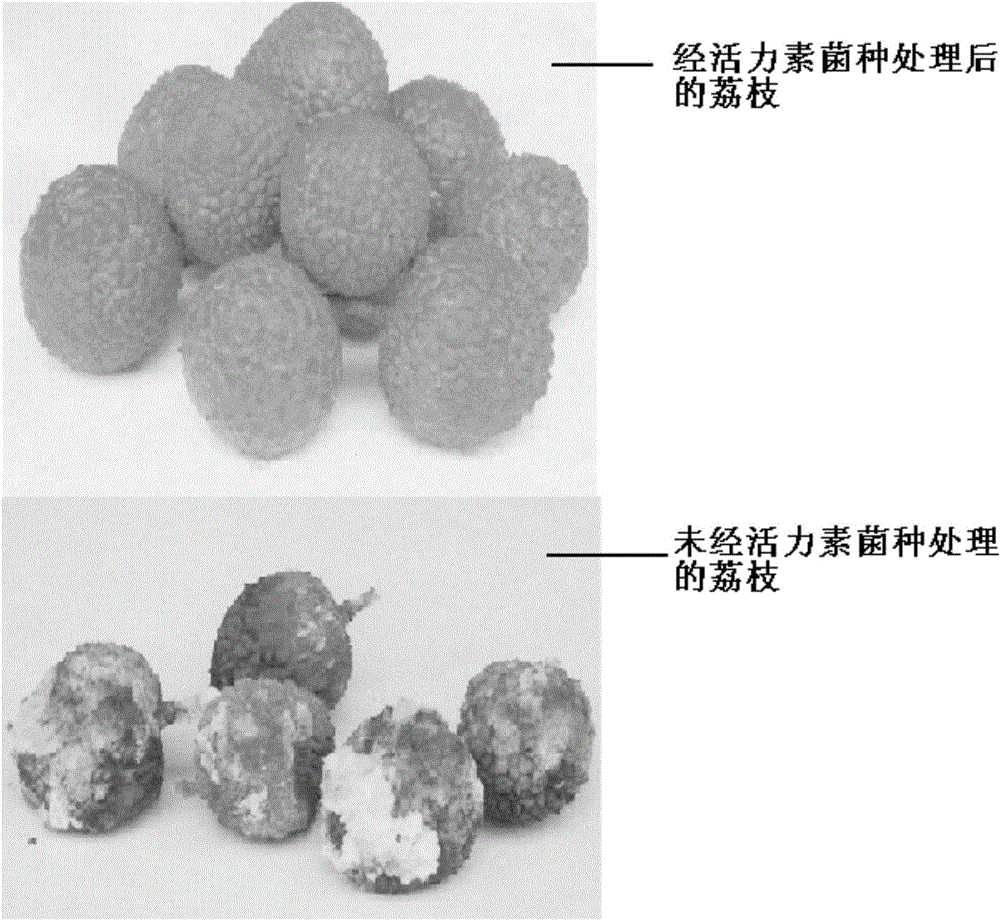

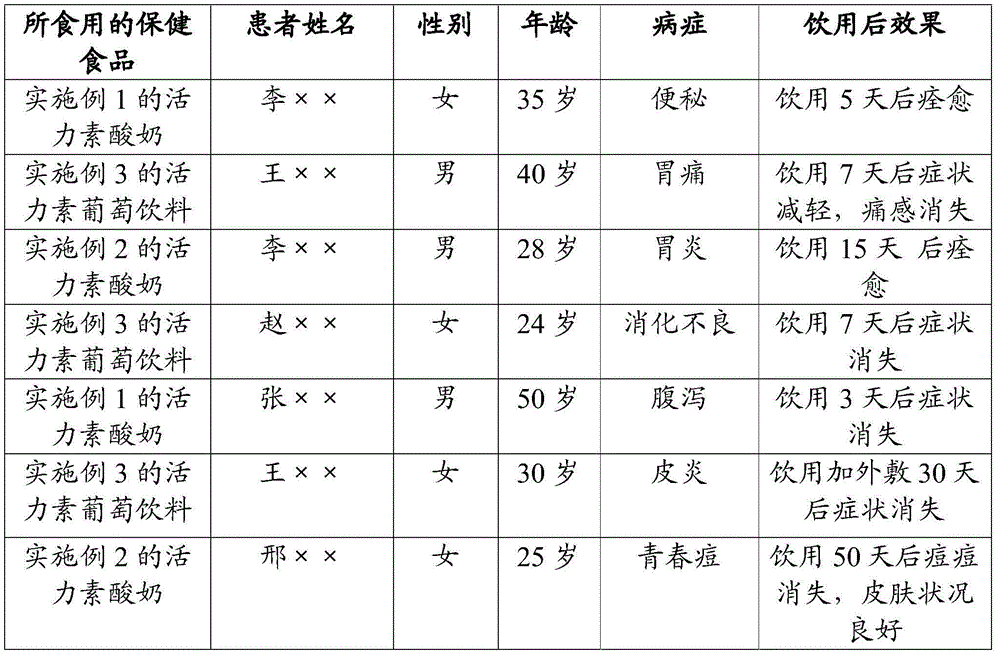

Active agent strain with strong fermentation capacity and health food

InactiveCN104673708AExtended shelf lifeGood treatmentMilk preparationFungiDiseaseIntestinal tract diseases

The invention discloses an active agent strain with strong fermentation capacity and a health food, belonging to the field of health foods. The active agent strain comprises the following components in parts by weight: 1-10 parts of yeast, 1-10 parts of lactic acid bacteria and 1-5 parts of kefir. The active agent strain disclosed by the invention has relatively-strong fermentation capacity under the compound action of yeast, lactic acid bacteria and kefir and can be used for fermenting various different fermentable organisms. A product obtained by fermenting a fermented substance by using the active agent strain not only is long in shelf life, but also is diversified in effect and has a better curative effect for intestinal tract diseases, diabetes mellitus, skin diseases and other diseases. In addition, the active agent strain has a favorable protecting function for anthocyanin so as to be capable of keeping the original color and luster of fruits and vegetables if being used for fermenting various fruits and vegetables or being used as a preservative for fruit and vegetable juices.

Owner:刘杰龙 +4

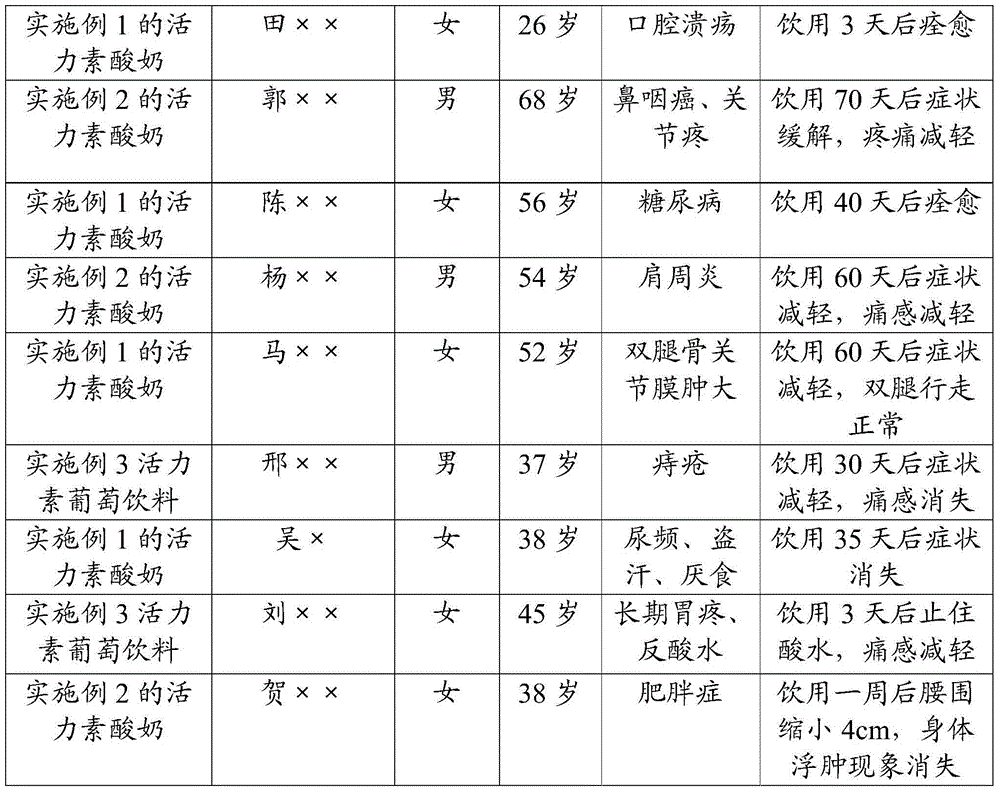

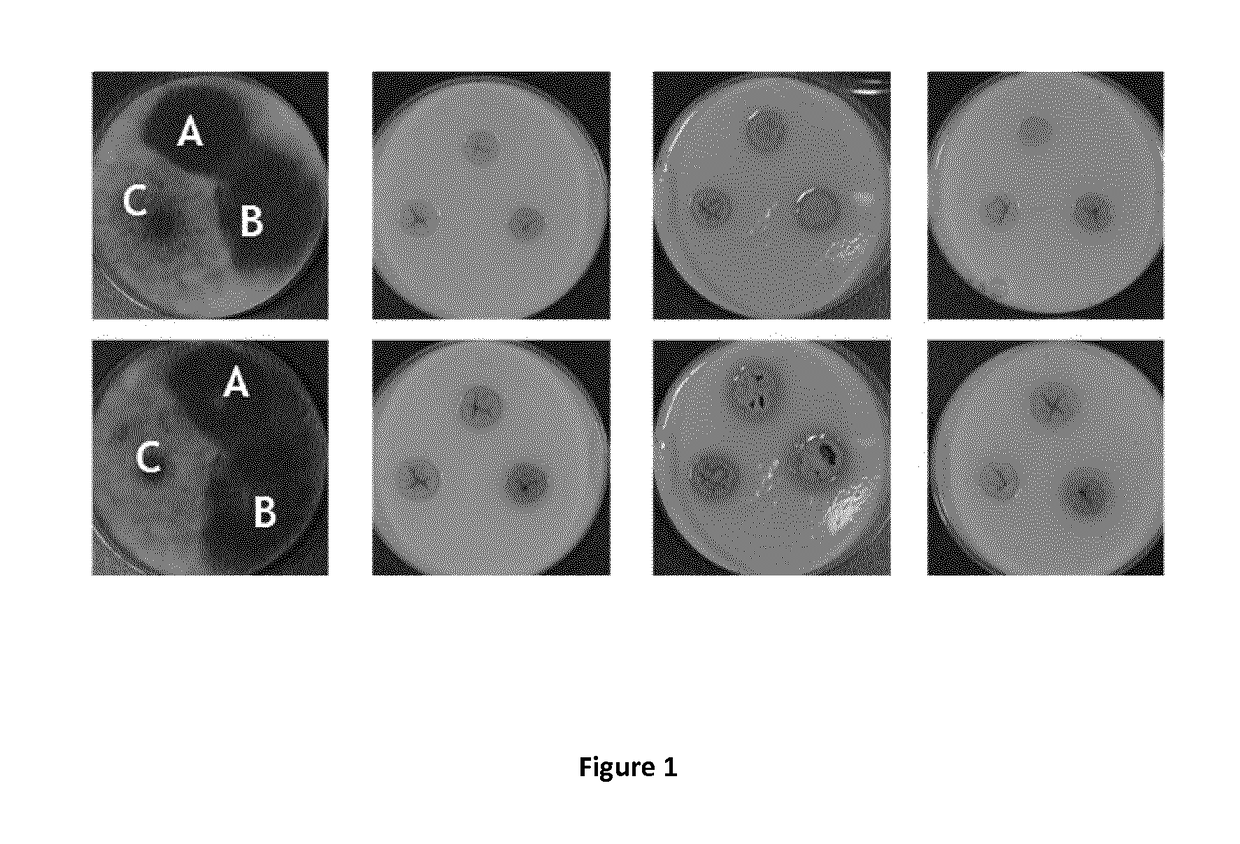

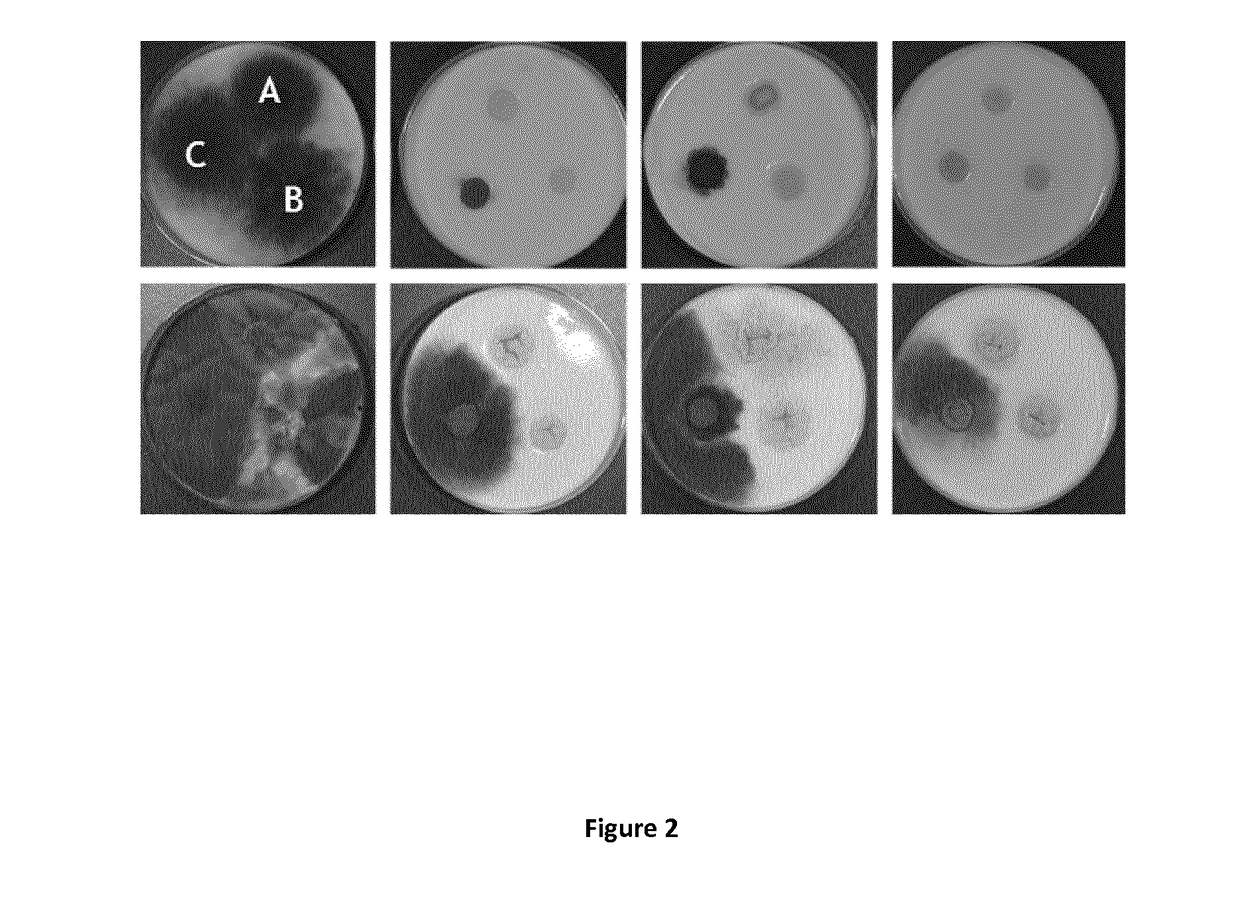

Lactobacillus fermentum bacteria with antifungal activity

InactiveUS20180249727A1Raise the pHReduced pHAntibacterial agentsAntimycoticsBacteroidesBiotechnology

The present invention relates to a bacterium of the species Lactobacillus fermentum having the ability to inhibit the growth of the fungus Penicillium solitum deposited under the accession No.: DSM32093 or the growth of the fungus Penicillium brevicompactum deposited under the accession No.: DSM32094 by at least 50%. The inhibitory activity can be determined in an assay comprising: (1) preparing a fermented milk product by: (a) inoculating a milk with the Lactobacillus fermentum in a concentration of at least 107 CFU / g and with a starter culture, (b) fermenting until a p H of 4.6 is reached, and (c) solidifying the fermented milk by the addition of agar; (2) generating at least one spot of the P. solitum or the P. brevicompactum on the agar solidified fermented milk with a concentration of 500 spores / spot and incubating the 1 same for 7 days at 25° C.; (3) determining the percent inhibition by determining the largest diameter of the colony formed by growth of the P. solitum or P. brevicompactum and expressing the diameter as percent of the largest diameter formed under the same conditions but in the absence of the Lactobacillus fermentum strain. The invention further relates to compositions comprising the bacterium, methods for producing fermented milk products using the bacterium and the products thus obtained.

Owner:CHR HANSEN AS

Metabolically engineered lactic acid bacteria and their use

Mutants of lactic acid bacteria including Lactococcus lactis which are defective in pyruvate formate-lyase production and / or in their lactate dehydrogenase (Ldh) production and methods of isolating such mutants or variants are provided. The mutants are useful in the production of food products or in the manufacturing of compounds such as diacetyl, acetoin and acetaldehyde and as components of food starter cultures. In particular, Lactococcus lactis DN223 deposited under the accession No. DSM 11036.

Owner:CHR HANSEN AS

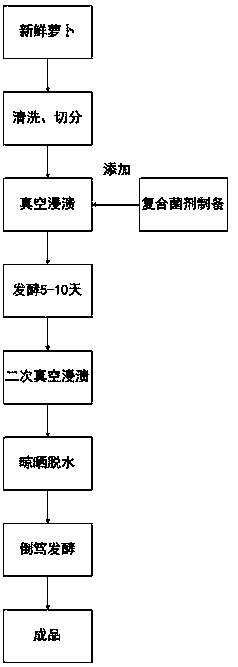

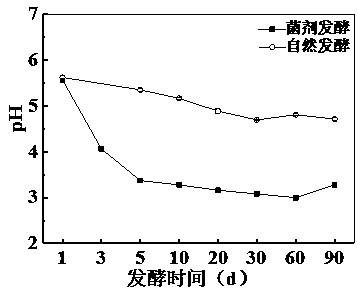

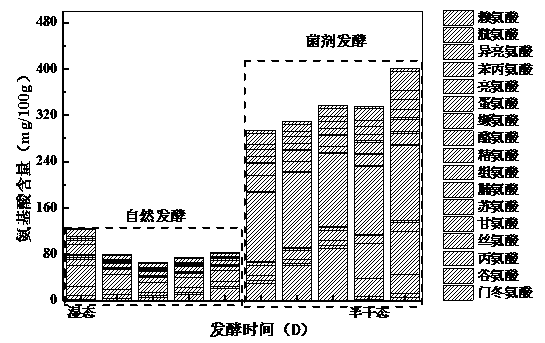

Method for preparing dried turnip by using composite bacterial agent

ActiveCN109259151AShorten the maturity cycleImprove qualityBacteriaYeast food ingredientsWeissella hellenicaRhodotorula species

The invention belongs to the field of food, and particularly relates to a method for preparing dried turnip by using a composite bacterial agent. The method comprises the following steps: (1) respectively performing high-density culture on strains of leuconostoc mesenteroides, weissella hellenica, declubhouseyomyces hansenii and rhodotorula glutinis; then, preparing bacterium powder according to the proportion of (4.8 to 5.2):(1.8 to 2.4):(0.8 to 1.2):(0.8 to 1.2), thus obtaining the composite bacterial agent. A vacuum soaking mode is used for injecting the composite bacterial agent into turnip; the fermentation is fast started to form precusor substances; drying and dewatering and post aging storage are performed; the influence on the fermentation by environment factors is avoided. The aging period of the dried turnip is shortened; the growth of gram-negative bacteria such as coliform bacteria and pseudomonas attached onto the surfaces of the dried turnip can be inhibited; the contents of nitrite and biogenic amine are reduced; the stability and the safety of the product are improved; the prepared dried turnip is sour, cool and delicious; the natural flavor is good; the dried turnip can be eaten without manual material mixing and seasoning.

Owner:SICHUAN DONGPO CHINESE PAOCAI IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com