Quark base mix having enhanced taste properties

A technology of mixture and matrix composition, applied in the field of quark cheese, can solve the problems of small product market and complex technology, and achieve the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

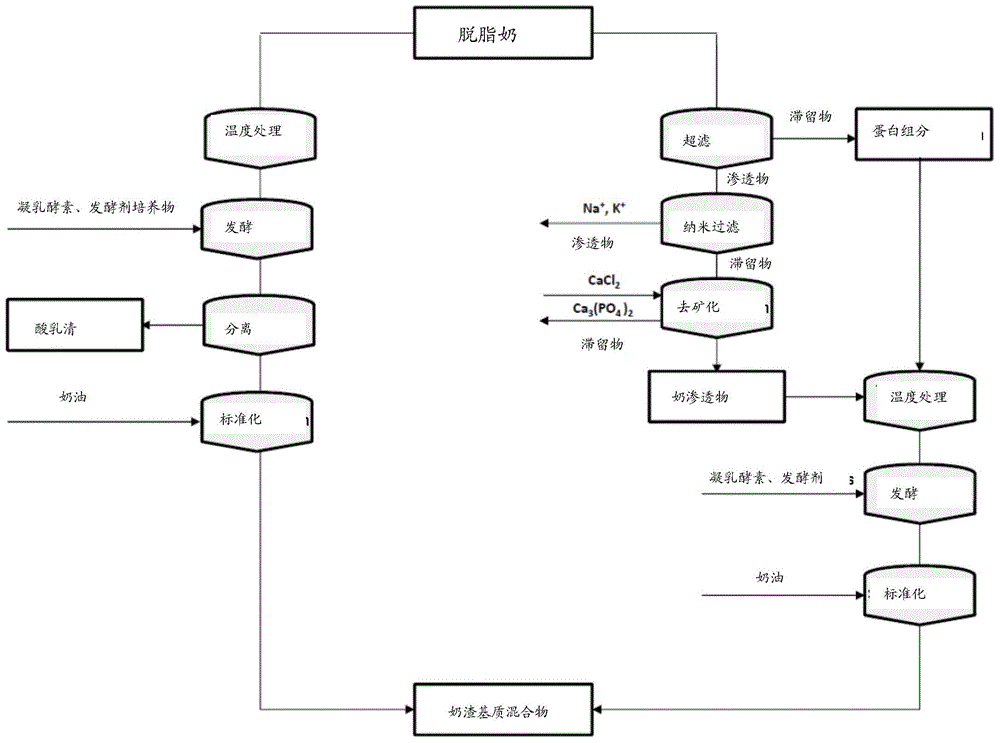

Method used

Image

Examples

Embodiment 1

[0089] 4 kg of skim milk were subjected to ultrafiltration at 20° C. using a spiral wound membrane (selectivity 25 000 Daltons). The protein-rich retentate was separated off and the permeate was subjected to nanofiltration at 20°C using a spiral wound membrane (500 Dalton selectivity). Sodium and potassium salts are separated along with the permeate. The retentate was subsequently treated by adding an aqueous calcium chloride solution adjusted to pH=6 with NaOH, and the phosphate was precipitated as calcium phosphate. The resulting permeate was combined with the protein-rich retentate obtained in the first step and treated at 88 °C for 6 min to denature the resulting protein. Blend the mixture into a mixture of two starter cultures (i) and (ii) (60:40 by weight) with rennet, stir at 30°C for about 2 hours, separate Ditch the acid whey as a liquid component. The remaining quark cheese mixture was adjusted to a dry matter content of 18% by weight and a protein content of 12% ...

Embodiment 2 to 4, comparative Embodiment C2 to C4

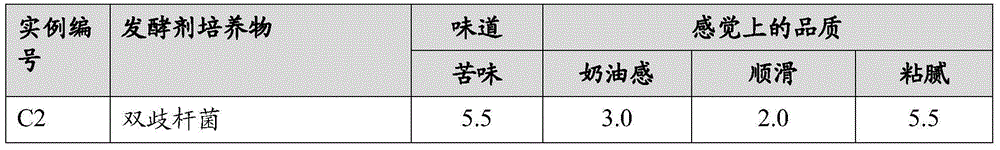

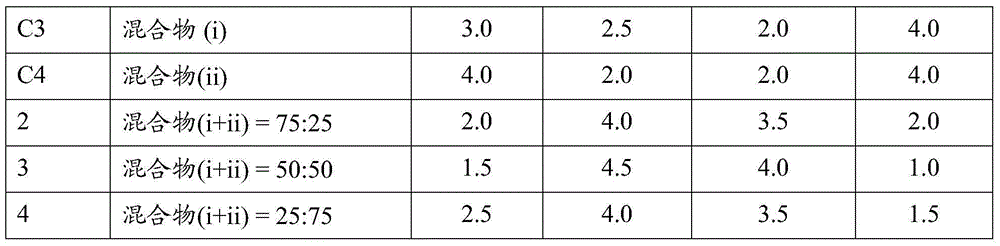

[0093]Example 1 was repeated, but with a different starter culture. The taste and sensory properties of the product were then evaluated on a scale of 1 (=not applicable) to 6 (=perfectly applicable) by a panel of 5 experienced testers. The results are summarized in Table 1. Examples 2 to 7 are examples according to the present invention, and example C2 still plays a comparative role. Means of evaluations are described.

[0094] Table 1

[0095] Taste and Sensory Evaluation of Quark Cheese Base Mix

[0096]

[0097]

[0098] The above tests and comparative tests clearly show that the choice of starter culture has an important influence on the taste and sensory properties of the quark cheese base mix. Quark cheese base mix with optimum properties (ie least bitterness, most creaminess and moreover not leaving a sticky impression) by using the combination according to the invention of mixtures (i) and (ii) in a weight ratio of 1:1 get.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com