Lactobacillus fermentum bacteria with antifungal activity

a technology of lactobacillus fermentum and antifungal activity, which is applied in the direction of antibacterial agents, microorganisms, milk preparations, etc., can solve the problems of spoilage of fermented dairy products, the inability to support the growth of most microorganisms, and the difficulty of developing cultures with antifungal effects, so as to reduce the post-acidification effect, reduce the ph of milk products, and reduce the effect of ph

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

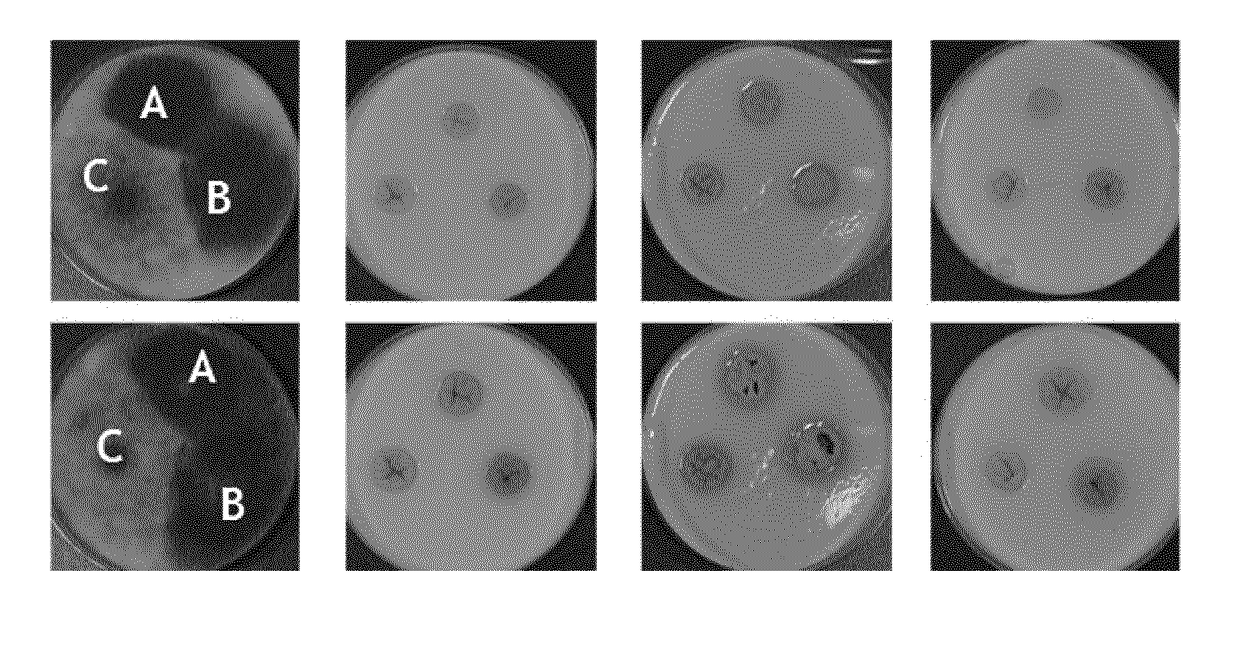

[0146]Semi-Quantitative Analysis of the Inhibitory Effect of Lb. Fermentum CHCC14591 Against Different Yeast and Mold Contaminants and Diacetyl Production

[0147]For the semi-quantitative analysis of the inhibitory effect of Lb. fermentum CHCC14591, an agar-assay was used, resembling the manufacturing process and product of yoghurt:

[0148]Reduced-fat (1.5% w / v) homogenized milk was heat-treated at 90±1° C. for 20 min and cooled immediately. A commercial starter culture (F-DVS Mild 2.0) was inoculated at 0.02% (v / w), and the inoculated milk was distributed into 200 ml bottles. One bottle was inoculated with Lb. fermentum CHCC14591 in total concentration of 2×107 CFU / g, two bottles were inoculated with either of two commercial bioprotective cultures (FreshQ®4 and Holdbac® YM-C Plus) in recommended dosages (100 U / T and 20 DCU / 100 L for FreshQ®4 and Holdbac® YM-C Plus, respectively), and one bottle was used as a reference and only inoculated with the starter culture. All bottles were incub...

example 2

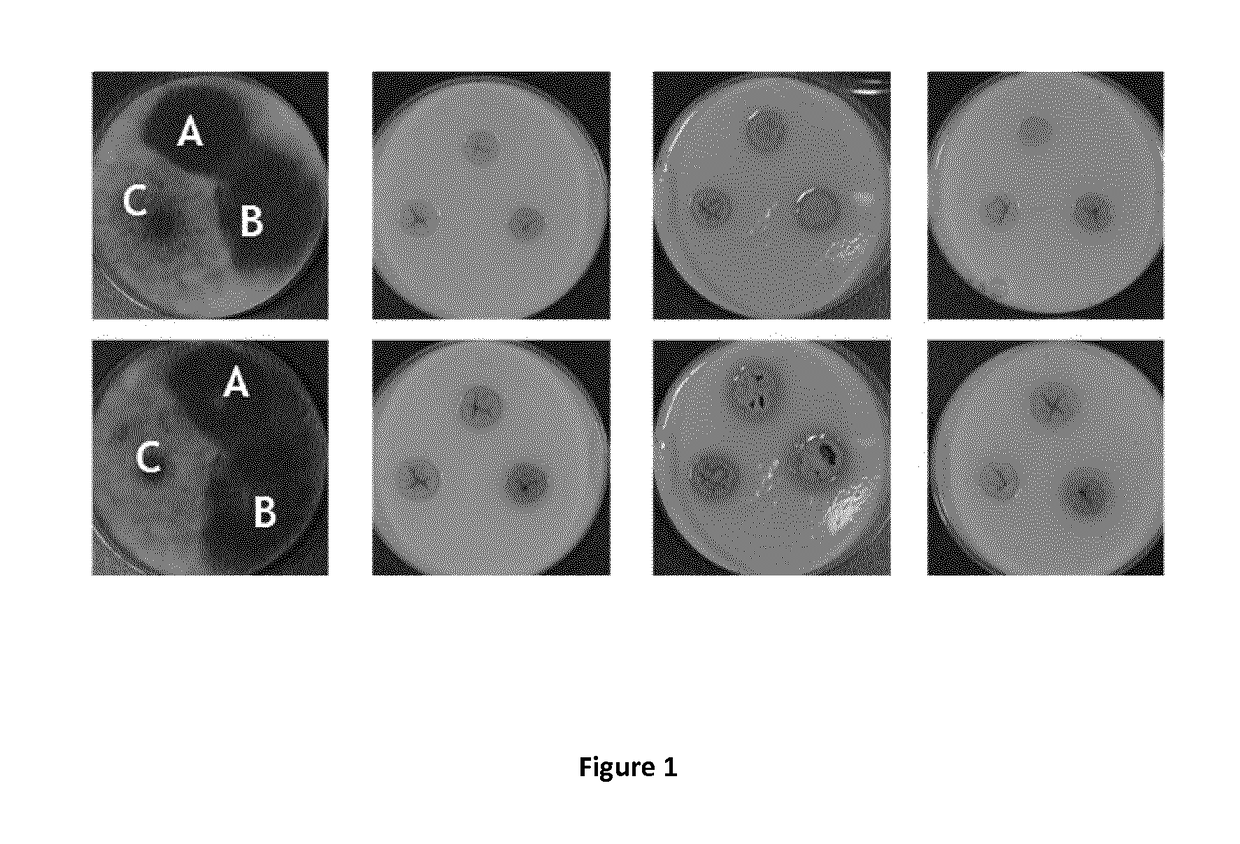

[0159]Semi-Quantitative Analysis of the Inhibitory Effect of Lb. Fermentum CHCC14591 in Combination with Lb. Rhamnosus CHCC15860 Against Different Mold Contaminants

[0160]For the semi-quantitative analysis of the inhibitory effect of a combination of Lb. fermentum CHCC14591 and Lb. rhamnosus CHCC15860, an agar-assay was used, resembling the manufacturing process and product of yoghurt:

[0161]Reduced-fat (1.5% w / v) homogenized milk was heat-treated at 90±1° C. for 20 min and cooled immediately. A commercial starter culture (F-DVS Mild 2.0) was inoculated at 0.02% (v / w), and the inoculated milk was distributed into 200 ml bottles. One bottle was inoculated with Lb. rhamnosus CHCC15860 in total concentration of 1×107 CFU / g, one bottle was inoculated with Lb. fermentum CHCC14591 in total concentration of 1×107 CFU / g, one bottle was inoculated with Lb. fermentum CHCC14591 and Lb. rhamnosus CHCC15860 each in concentration of 5×106 CFU / g, and one bottle was used as a reference and only inocu...

example 3

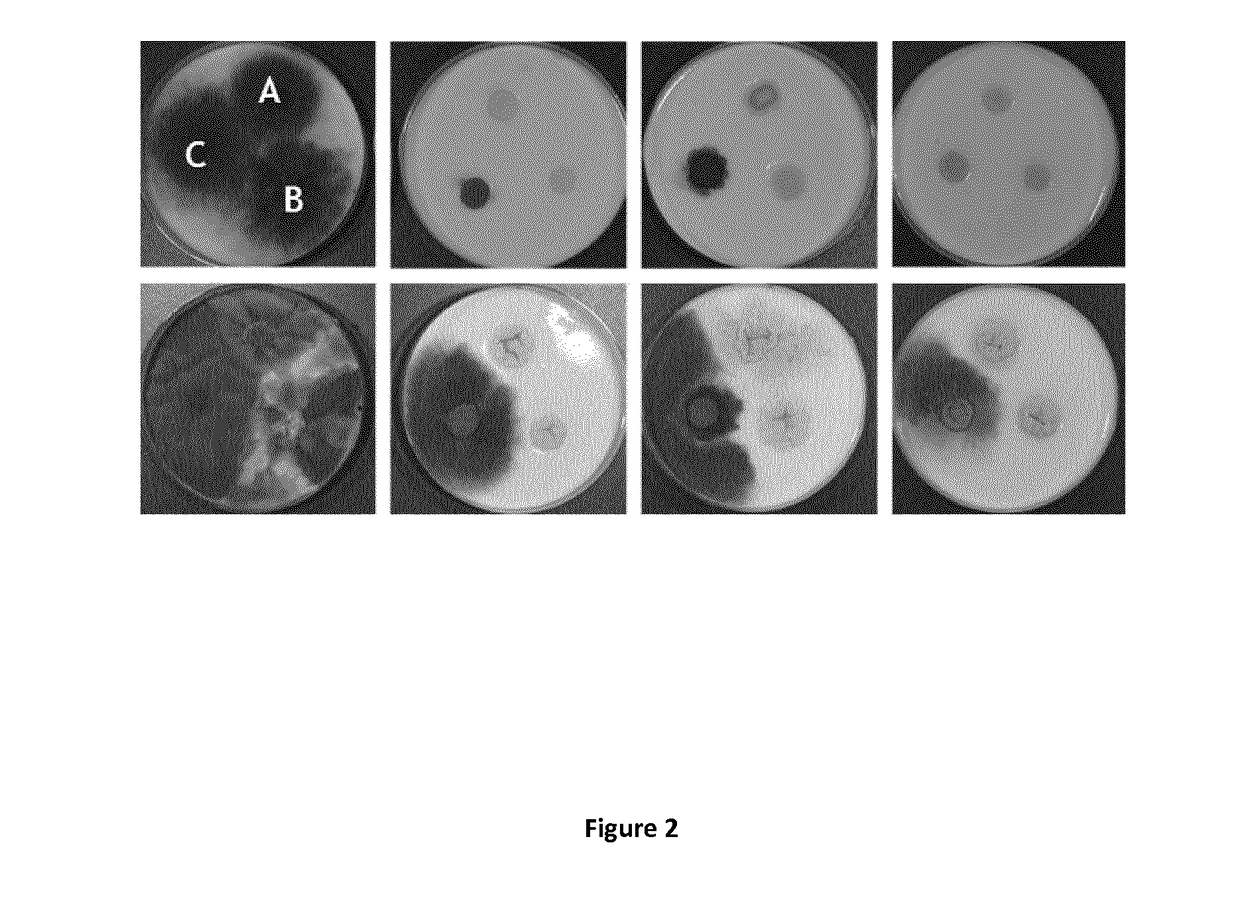

[0164]Semi-Quantitative Analysis of the Inhibitory Effect of Ten Lb. Fermentum Strains Against Different Mold Contaminants

[0165]For the semi-quantitative analysis of the inhibitory effect of ten Lb. fermentum strains, an agar-assay was used, resembling the manufacturing process and product of yoghurt:

[0166]Reduced-fat (1.5% w / v) homogenized milk was heat-treated at 90±1° C. for 20 min and cooled immediately. A commercial starter culture (F-DVS YF-L901) was inoculated at 0.02% (v / w), and the inoculated milk was distributed into 200 ml bottles. Ten bottles were inoculated with the Lb. fermentum strains in concentrations of 1×107 CFU / g and one bottle was used as a reference and only inoculated with the starter culture. All bottles were incubated in a water bath at 43±1° C. and fermented at these conditions until pH of 4.60±0.1 was reached. After fermentation, the bottles were vigorously shaken to break the coagulum and cooled on ice. Then the fermented milk was warmed to a temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com