Greek-flavored fermented milk made through MPC liquid and preparation method of Greek-flavored fermented milk

A technology for fermented milk and flavor, applied in the directions of bacteria, application, and lactobacilli used in food preparation, can solve the problems of higher pipe diameter requirements, inability to use production equipment, and rough product status, reducing hardware investment and reducing Emissions, the effect of optimizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

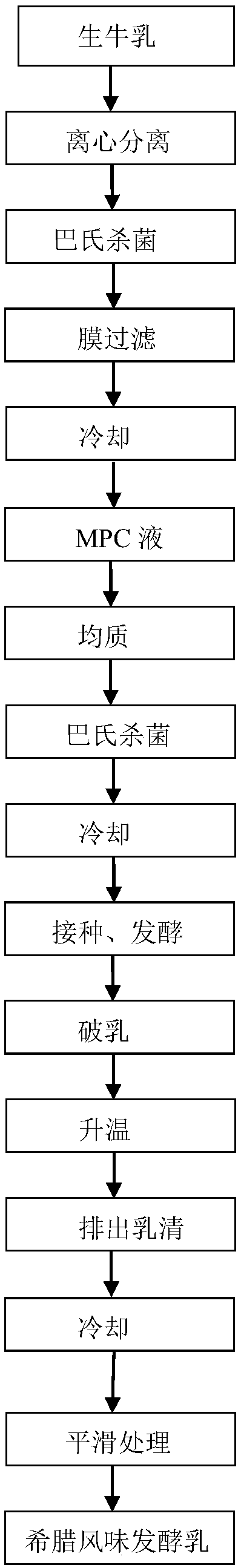

[0045] The method for making Greek flavor fermented milk by utilizing MPC liquid comprises the following steps:

[0046] (1) Raw milk shall be received and temporarily stored after passing the inspection. The temporary storage temperature shall be ≤7°C and the temporary storage time shall be ≤24 hours.

[0047] (2) The raw milk is preheated to 60° C. for centrifugation to obtain skim milk, the fat content of which is ≤0.1%.

[0048] (3) Pasteurize the skim milk at 80° C. for 15 seconds. The sterilized material is temporarily stored in the milk tank.

[0049] (4) The skim milk is filtered through an ultrafiltration membrane, and the retained liquid is the MPC liquid. The protein content of the MPC solution is 5.0%, the fat is 0.2%, and the operating temperature of the membrane is ≤50°C.

[0050] (5) The MPC liquid is homogenized and pasteurized, the homogenization pressure is 180-200 bar, the homogenization temperature is 55-60°C, the pasteurization temperature is 95°C, and ...

Embodiment 2

[0059] The method for making Greek flavor fermented milk by utilizing MPC liquid comprises the following steps:

[0060] (1) Raw milk shall be received and temporarily stored after passing the inspection. The temporary storage temperature shall be ≤7°C and the temporary storage time shall be ≤24 hours.

[0061] (2) Raw milk is preheated to 60°C for centrifugation and standardization to obtain standardized milk with a fat content of 0.5%.

[0062] (3) Pasteurize the standardized milk at 85° C. for 15 seconds. The sterilized material is temporarily stored in the milk tank.

[0063] (4) The standardized milk is filtered through an ultrafiltration membrane, and the retentate is the MPC solution. The protein content of the MPC solution is 6%, the fat is 1.1%, and the membrane operating temperature is ≤50°C

[0064] (5) The MPC liquid is homogenized and pasteurized, the homogenization pressure is 200-220 bar, the homogenization temperature is 60-65°C, the pasteurization temperatu...

Embodiment 3

[0074] The method for making Greek flavor fermented milk by utilizing MPC liquid comprises the following steps:

[0075] (1) Accept raw milk after passing the inspection;

[0076] (2) Raw milk is preheated to 55° C., and centrifuged to obtain skim milk. After centrifugation, the fat content in the skim milk is ≤0.1%;

[0077] (3) Sterilize the skim milk at 72°C for 15 seconds.

[0078] (4) The skim milk is filtered through an ultrafiltration membrane, the concentration factor is 1.8-2.0, and the protein is concentrated to 5.5% in the MPC liquid, and the fat is ≤0.5%;

[0079] (5) The MPC liquid is cooled down to 2°C;

[0080] (6) The material is homogenized at 55°C, the homogenization pressure is 150-180bar, and the pasteurization temperature is 85°C for 30 minutes;

[0081] (7) The pasteurized material is cooled to 22°C and inoculated. The inoculated bacteria are Lactococcus lactis subsp. The ratio is 1:2:1:1, the total inoculum amount is 0.01%, and the unit is mass perce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com