Liquid dairy product and preparation method

A dairy product and liquid technology, applied in the field of dairy products, can solve problems such as poor stability, and achieve the effect of excellent stability and uniform dairy products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

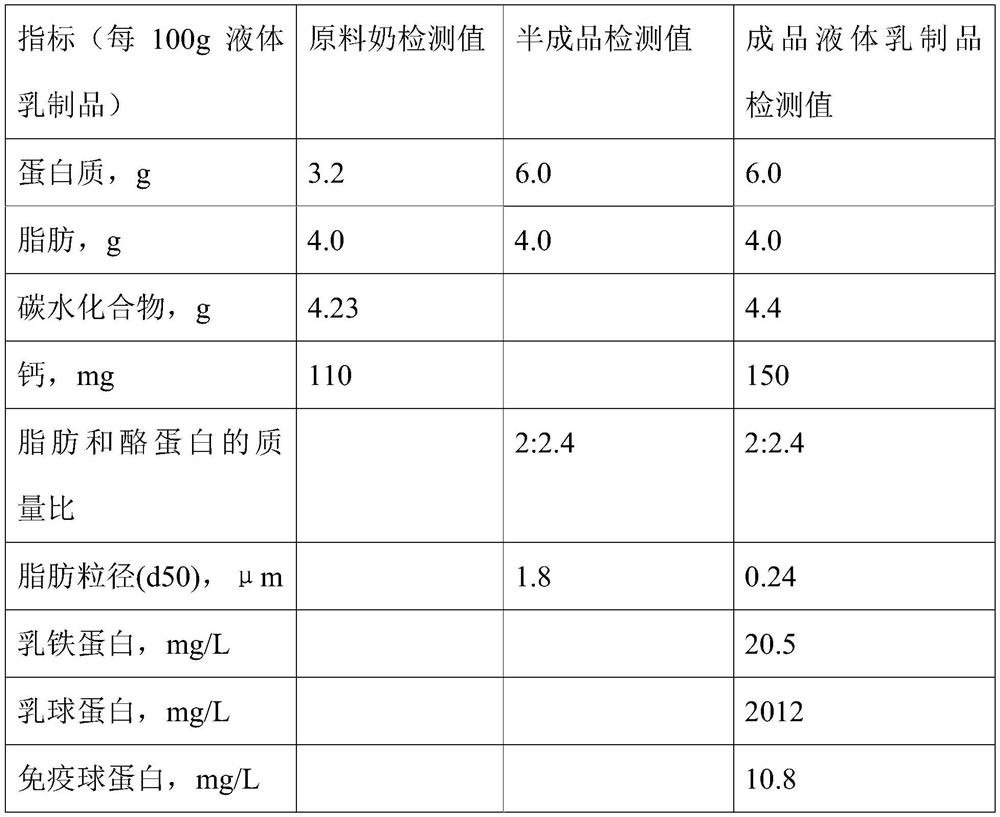

Embodiment 1

[0053] The present embodiment provides a kind of liquid dairy product preparation method, comprises the following steps:

[0054]1) Raw milk pretreatment: use raw milk as raw milk, filter it through a 50-mesh double filter to remove larger impurities or foreign matter, then preheat to 45°C, and use a milk cleaner to remove impurities by centrifugation (speed 4000rpm , 20 tons / h), remove most of the impurities and somatic cells, etc.

[0055] 2) Sterilization by centrifugal: pass the decontaminated raw milk through a centrifugal sterilizer with a rotation speed of 4000rpm, a time of 20 tons / h, and a temperature of 45°C to remove most of the spores and some bacteria.

[0056] 3) Fat standardization: standardize the fat of raw milk after sterilization, the speed of the centrifugal separation is 6000rpm, the temperature is 50°C, the time is 20 tons / h, and the fat is backfilled online as needed.

[0057] 4) Homogenization: The standardized raw milk is homogenized, the homogenizati...

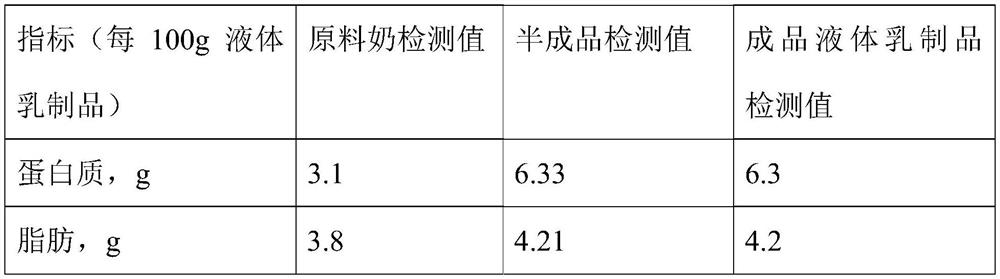

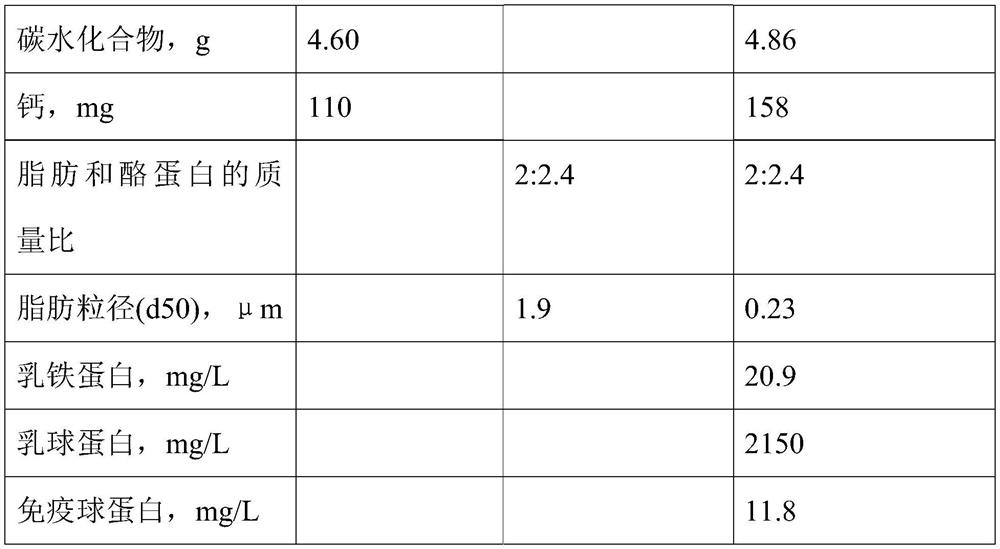

Embodiment 2

[0067] The present embodiment provides a kind of liquid dairy product preparation method, comprises the following steps:

[0068] 1) Raw milk pretreatment: use raw milk as raw milk, filter it through a 60-mesh double filter to remove larger impurities or foreign matter, then preheat to 65°C, and use a milk cleaner to remove impurities by centrifugation (speed 6000rpm , 15 tons / h), remove most impurities and somatic cells, etc.

[0069] 2) Centrifugal sterilization: the raw milk after cleaning is passed through a centrifuge at a speed of 6000 rpm, 15 tons / h, and a temperature of 65° C. to remove most of the spores and some bacteria.

[0070] 3) Fat standardization: standardize the fat of raw milk after sterilization, the speed of the centrifugal separation is 6500rpm, the temperature is 55°C, 15 tons / h, and the fat is backfilled online as needed.

[0071] 4) Homogenization: Standardized milk is homogenized at temperature: 65°C, total pressure 300bar, secondary pressure 50bar, ...

Embodiment 3

[0082] The present embodiment provides a kind of liquid dairy product preparation method, comprises the following steps:

[0083] 1) Raw milk pretreatment: use raw milk as raw milk, filter it through a 60-mesh double filter to remove larger impurities or foreign matter, then preheat to 50°C, and use a milk cleaner to remove impurities by centrifugation (speed 5000rpm , 18 tons / h), remove most impurities and somatic cells, etc.

[0084] 2) Centrifugal degerming: pass the decontaminated raw milk through a centrifugal degerming machine at a speed of 5500 rpm, a temperature of 50° C., and 20 tons / h to remove most of the spores and some bacteria.

[0085] 3) Fat standardization: standardize the fat of the sterilized raw milk, the centrifugal separation speed is 6500rpm, the temperature is 50°C, 20 tons / h, and the fat is backfilled online as needed.

[0086] 4) Homogenization: Standardized milk is homogenized at temperature: 75°C, total pressure 320bar, secondary pressure 60bar, to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com