Method for preparing dried turnip by using composite bacterial agent

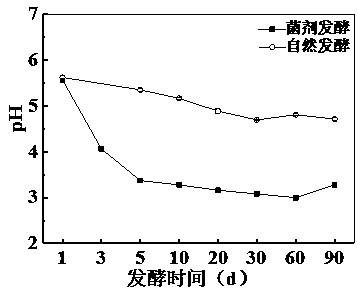

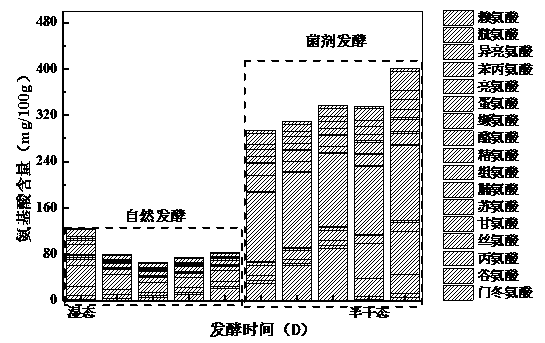

A technology of composite bacterial agent and dried radish, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc., can solve the problems of poor strengthening effect and achieve the purpose of maintaining a stable bacterial group structure, Effect of shortening ripening period and improving food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

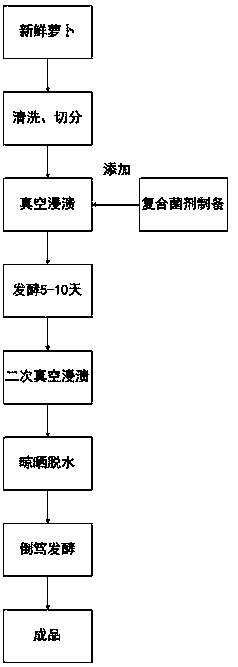

[0036] A method for preparing dried radish by using composite bacteria agent, comprising the following steps:

[0037] (1) Cultivate the strains of the four strains in high density respectively, then centrifuge at 3-5°C to take the sludge, add a protective agent, and vacuum freeze-dry to obtain the bacterial powder. The drying temperature is -60 to -50°C, and the vacuum degree is 1Pa. , time 30h, centrifugal speed is 10000rpm, freeze-dried to make powder respectively, bacterial strain Leuconostoc mesenteroides is bacterial agent A, bacterial strain Weissella hellenica is bacterial agent B, bacterial strain Debaryomyces hansenii is bacterial agent C, Rhodotorulaglutinis is microbial agent D, The number of viable bacteria in each bacterial agent is about 8×10 10 -1×10 11 cfu / g; then mix bacteria powder A, bacteria powder B, bacteria powder C and bacteria powder D at a mass ratio of 5:2:1:1 to form a composite bacterial agent. On a mass basis, the ratio of the protective agent ...

Embodiment 2

[0042] A method for preparing dried radish by using composite bacteria agent, comprising the following steps:

[0043] (1) Cultivate the strains of the four strains in high density respectively, then centrifuge at 3-5°C to take the sludge, add a protective agent, and vacuum freeze-dry to obtain the bacterial powder. The drying temperature is -60 to -50°C, and the vacuum degree is 1Pa. , time 30h, centrifugal speed is 10000rpm, freeze-dried to make powder respectively, bacterial strain Leuconostoc mesenteroides is bacterial agent A, bacterial strain Weissella hellenica is bacterial agent B, bacterial strain Debaryomyces hansenii is bacterial agent C, Rhodotorulaglutinis is microbial agent D, The number of viable bacteria in each bacterial agent is about 8×10 10 -1×10 11 cfu / g; then mix bacteria powder A, bacteria powder B, bacteria powder C and bacteria powder D according to the mass ratio of 5.1:2.3:0.8:0.8, which is the composite bacterial agent. On a mass basis, the ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com