Efficient paint spraying device for surface of motor shell

A motor shell, high-efficiency technology, applied to the surface coating liquid device, coating, etc., can solve the problems of wasting time, not having fast drying, low working efficiency of painting equipment, etc., to improve work efficiency and avoid impact Healthy, time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

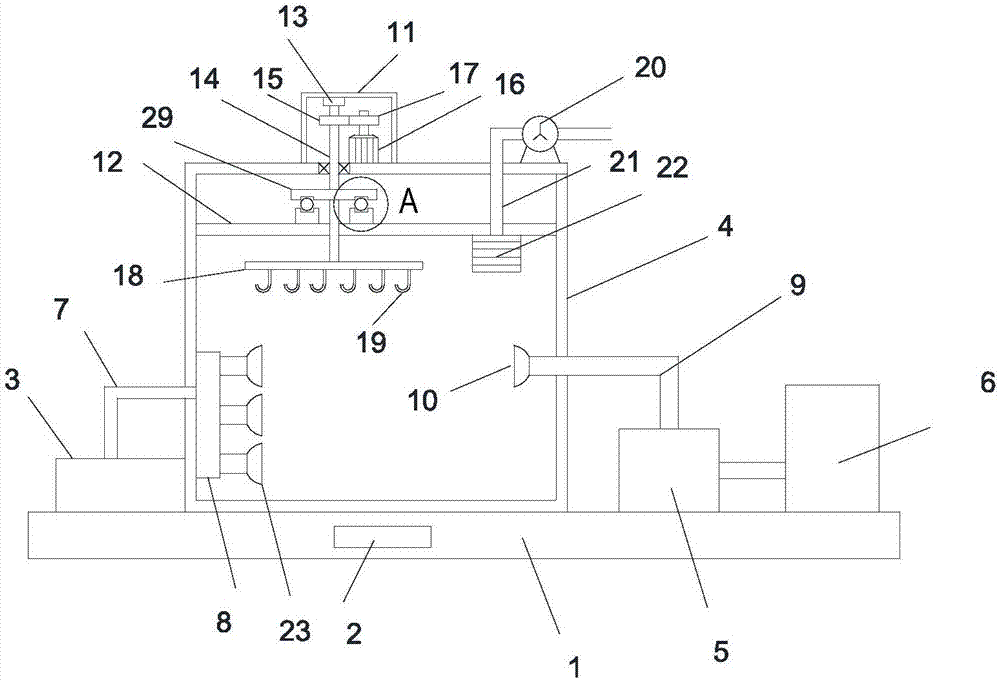

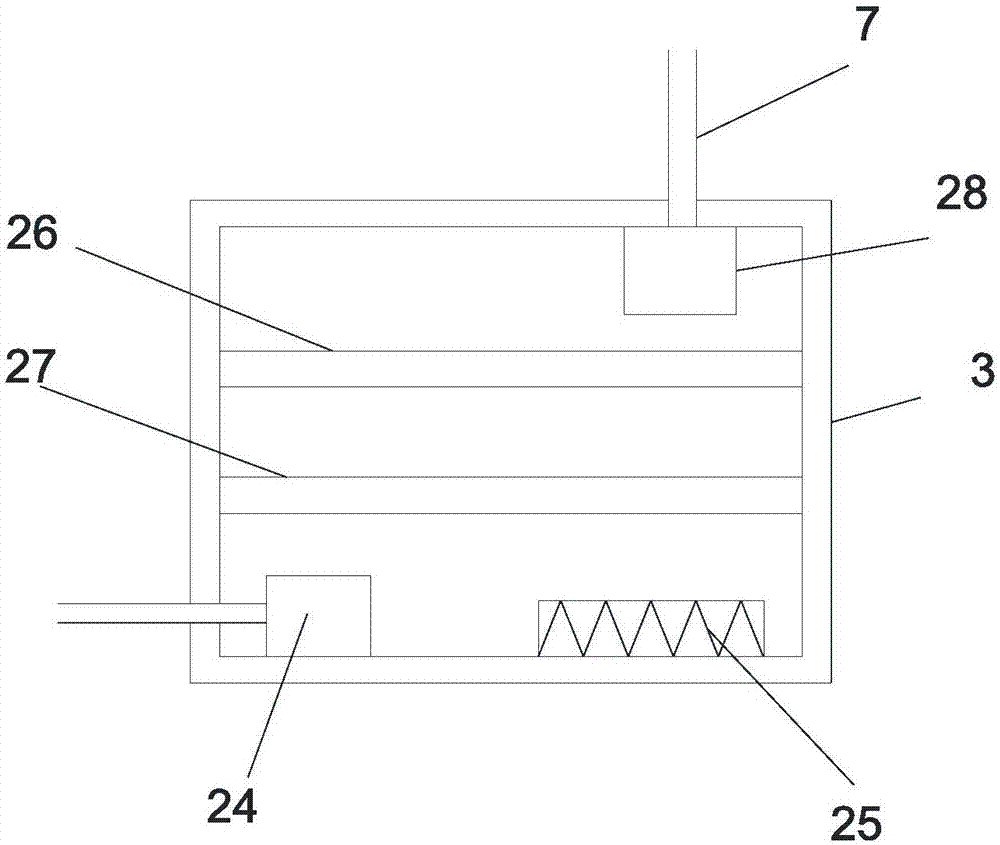

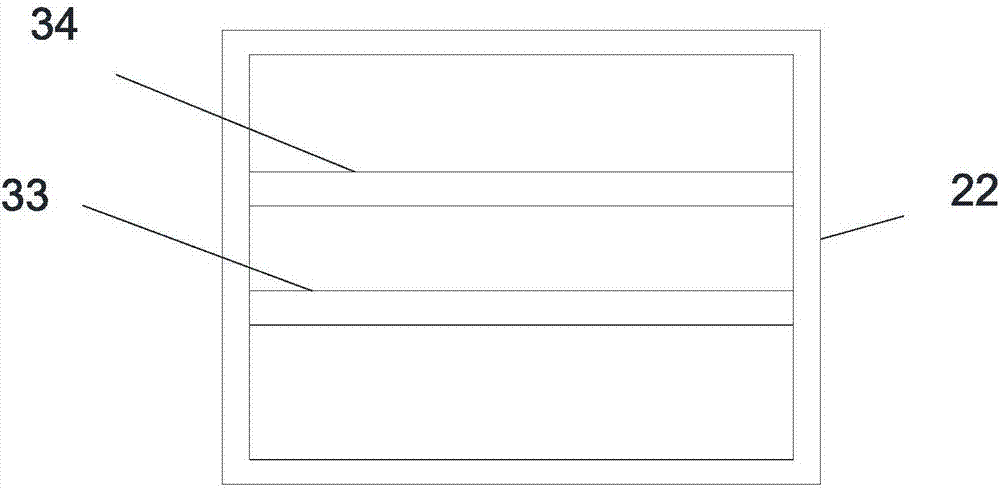

[0020] see Figure 1-4 , a high-efficiency painting device for the surface of a motor shell, comprising a support base plate 1, characterized in that: the side of the support base plate 1 is fixedly installed with a control box 2, and the top of the support base plate 1 is provided with an air supply box 3, a paint spraying room 4, and a delivery pump 5 and the paint storage box 6, the top of the air supply box 3 is provided with a conveying air duct 7, and the inner wall of the spray booth 4 is fixedly equipped with an air collecting duct 8, and the conveying air duct 7 is away from the air supply box 3 and runs through the spray booth to the right 4, the left side wall is in communication with the air collecting pipe 8; the inlet end of the delivery pump 5 is communicated with the paint storage tank 6 through the delivery pipe, and the outlet end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com