Self-heat-insulation brick producing device

A technology of self-insulating blocks and production equipment, which is applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., can solve the problems of no production equipment for block bricks, achieve good economic benefits, compact structure, and promote shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Self-insulating block brick production device one

[0035] A production device for self-insulating block bricks using steel slag as raw material, that is, a production device for self-insulating block bricks. The production process of block bricks generally includes: batching and material process-(self-insulating block) pressing Material forming process - steam curing process - injection molding process - palletizing.

[0036] The production raw materials mentioned here are the production raw materials obtained after the steel slag is crushed by a crusher and ball milled by a ball mill, as well as cement, additives and other production raw materials.

[0037] A self-insulating block brick production device, which includes a batching and material device 1, a pressure forming device 2, a transfer system, a steam curing device 5, an injection molding device 6, and the like.

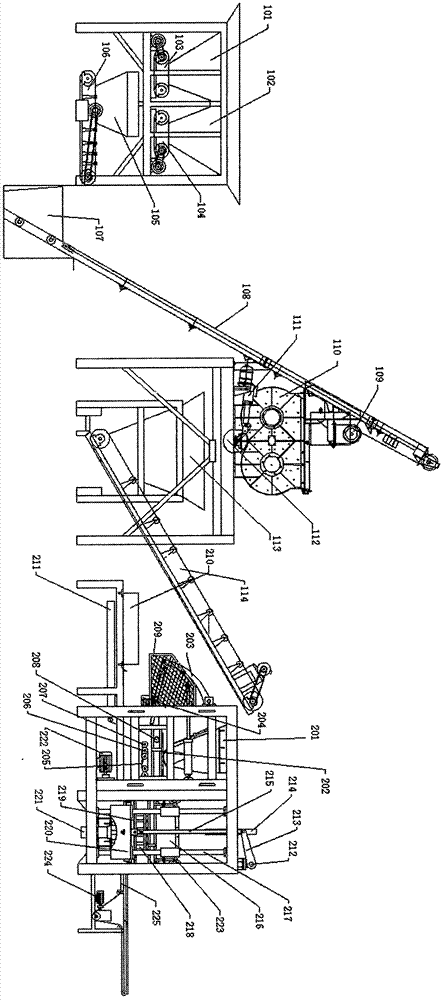

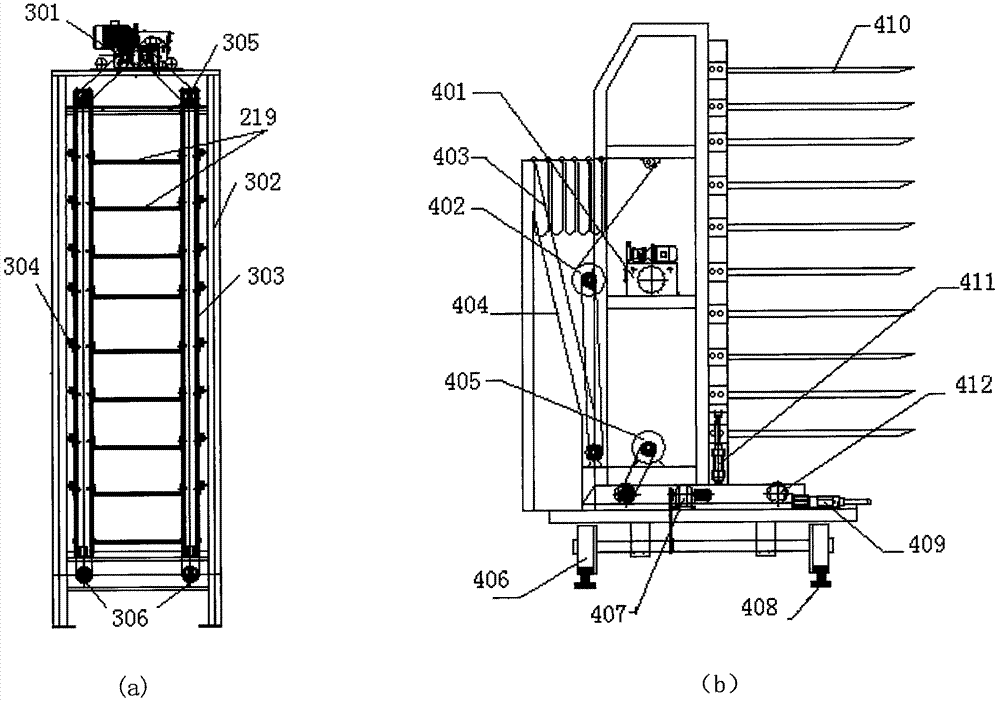

[0038] figure 1 It is a structural schematic diagram of the batching and material devi...

Embodiment 2

[0058] Example 2 Self-insulating block brick production device 2

[0059] A production device for self-insulating block bricks using steel slag as raw material, that is, a production device for self-insulating block bricks. The production process of block bricks generally includes: batching and material process-(self-insulating block) pressing Material forming process - steam curing process - injection molding process - palletizing.

[0060] The production raw materials mentioned here are the production raw materials obtained after the steel slag is crushed by a crusher and ball milled by a ball mill, as well as cement, additives and other production raw materials.

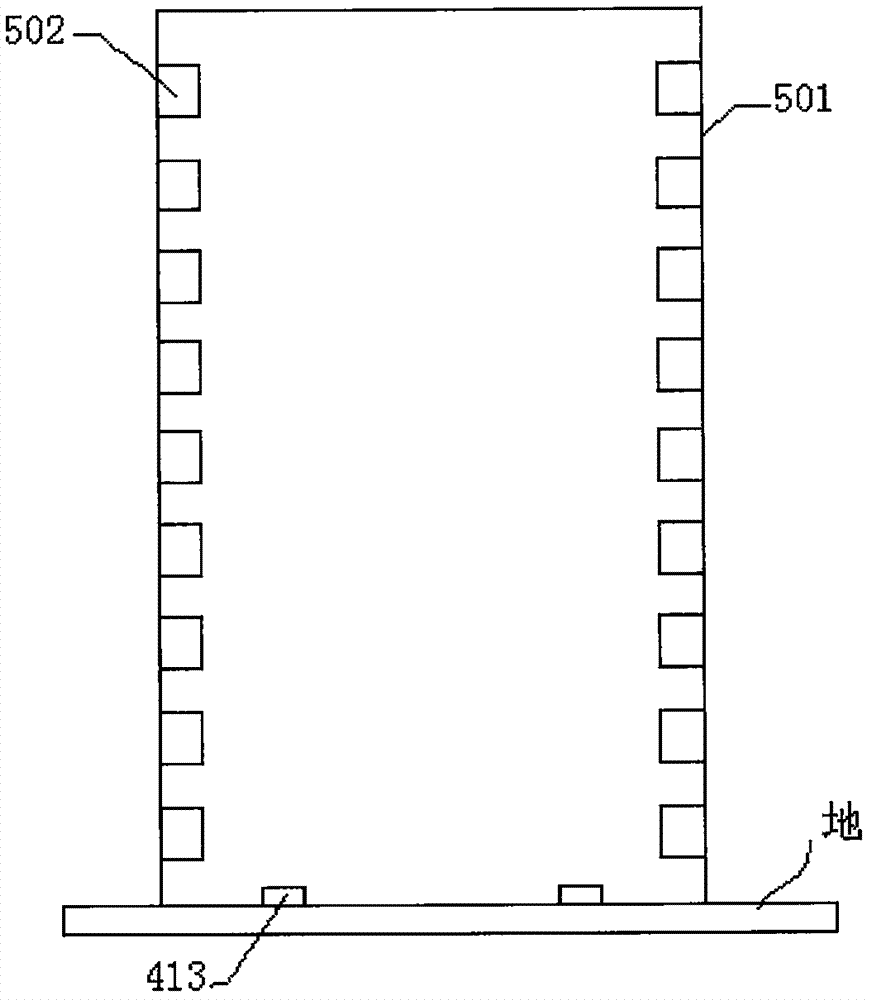

[0061] A self-insulating block brick production device, which includes a batching and material device 1, a pressure forming device 2, a transfer system, a steam curing device 5, an injection molding device 6, and the like. The self-insulating block brick production device of the present embodiment also contains b...

Embodiment 3

[0066] Example 3 Self-insulating block brick production device three (cement foaming-foam injection molding two-in-one device)

[0067] In general, in the investment of production plants, the production equipment is expensive, which often accounts for a large proportion of the investment amount (producers who purchase production equipment often calculate when to recover the cost). In addition, at the same time, there may also be a "path dependence problem" in the market— — That is, the market tends to prefer to use existing, “familiar” (self-insulating) blocks (bricks)—therefore, in the process of equipment development, the applicant should not only (should) consider that the new brick production device is different, but also (should) Considering that traditional self-insulating cement foam block bricks can be produced (considering traditional self-insulating block brick factory equipment, thus reducing the economic risk of setting up a factory), it belongs to a general inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com