Double-mode hybrid transmission device for commercial vehicle

A technology of hybrid power and transmission devices, which is applied in the direction of power devices, hybrid vehicles, pneumatic power devices, etc., can solve the problems of small transmission ratio range and difficult working conditions, and achieve the expansion of speed ratio range, increase of power density, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

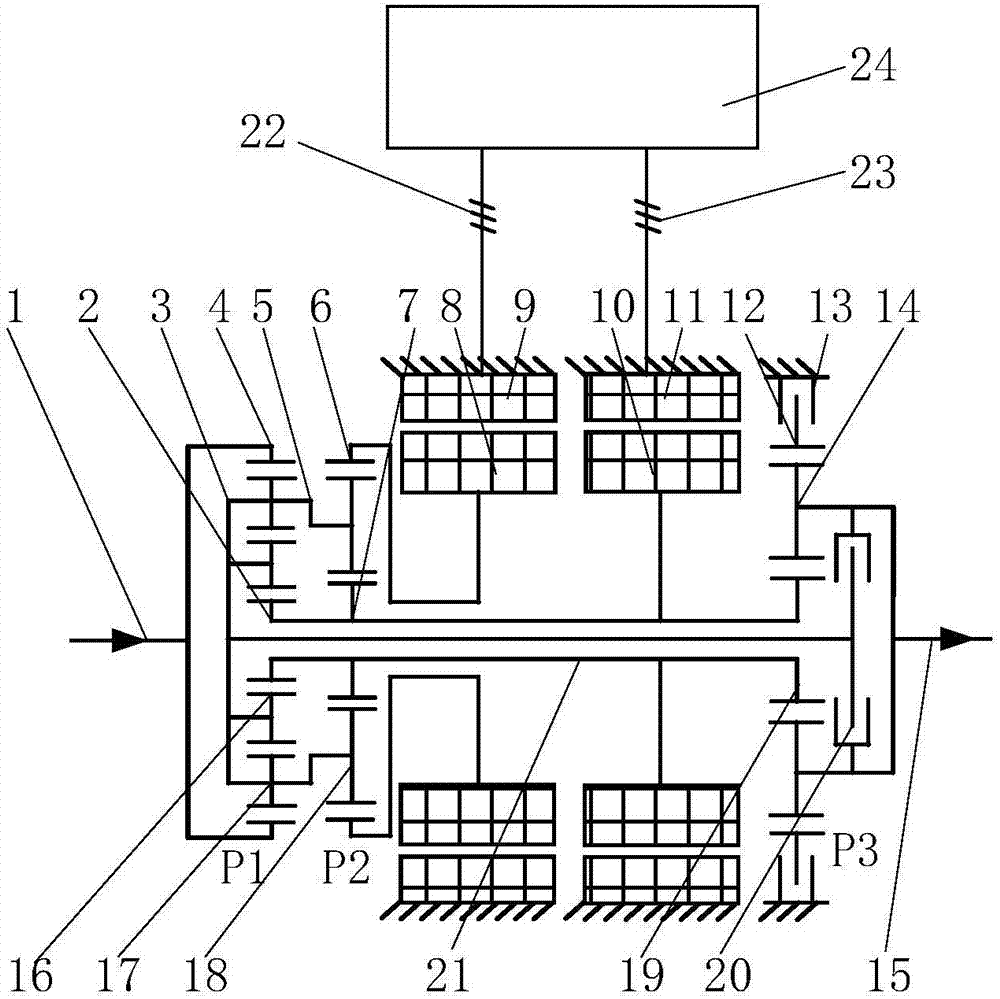

[0014] Embodiment 1, see attached figure 1 , a commercial vehicle dual-mode hybrid power transmission device, which includes: a motor controller 24, and three planetary rows arranged coaxially, two motors, a first clutch 20, and a first brake 13;

[0015] The three planetary rows are: internal and external meshing double star row P1, ordinary planetary row P2, and deceleration planetary row P3; among them, the internal and external meshing double star row P1 is composed of the first sun gear 2 and the first ring gear installed on the first planet carrier 3 4. The first planetary gear 16 and the second planetary gear 17; the ordinary planetary row P2 is composed of the second ring gear 6, the second sun gear 7 and the third planetary gear 18 installed on the second planet carrier 5; the deceleration planet The row P3 is composed of the third ring gear 12 and the third sun gear 19 installed on the third planetary carrier 14; the internal and external meshing double star row P1 a...

Embodiment 2

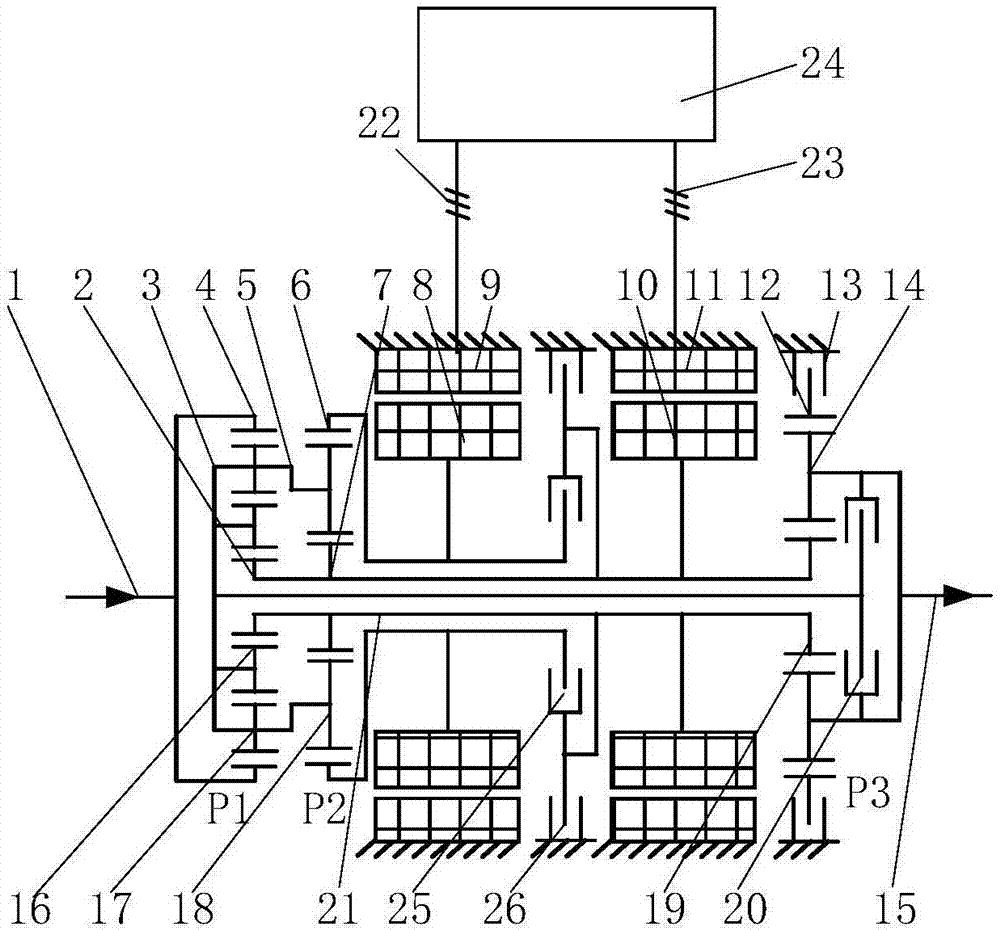

[0026] Embodiment 2, see attached figure 2 , on the basis of Embodiment 1, the second clutch 25 and the second brake 26 are added; the driving end of the second clutch 25 is connected with the second ring gear 6 and the rotor 8 of the first motor respectively, and the passive end is connected with the third sun gear 19. The rotor 10 of the second motor is connected; the driven end of the second brake 26 is connected to the casing, and the driving end is connected to the driven end of the second clutch 25 and the shaft 21 . Thus, 4 more mechanical gears can be obtained.

[0027] Its mode switching logic is shown in the following table:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com