Dumping type container truck

A technology for trucks and box dumping, which is applied in the direction of parallel load-bearing vehicles, etc., can solve the problem that boxes need to be tilted to unload the chassis, and achieve the effect of safe and smooth box dumping operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

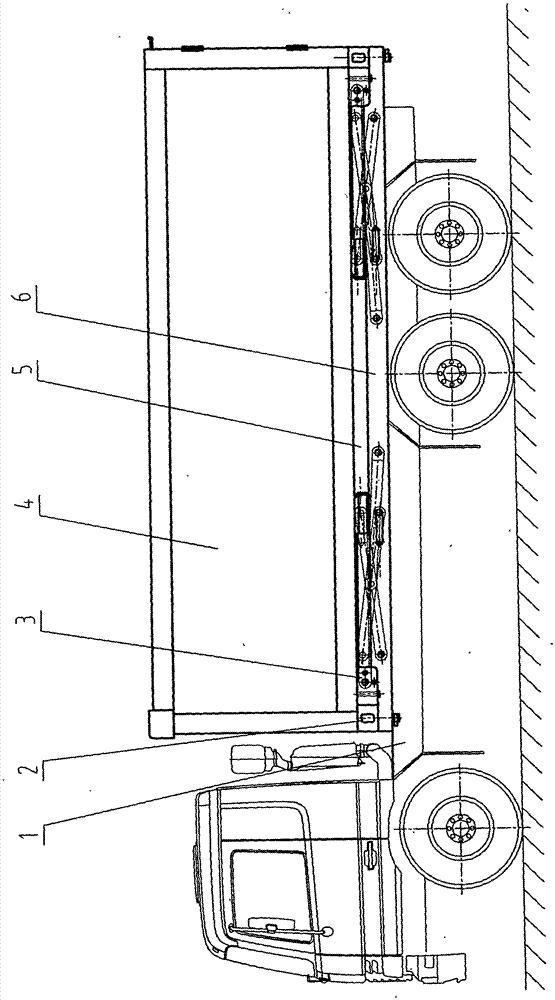

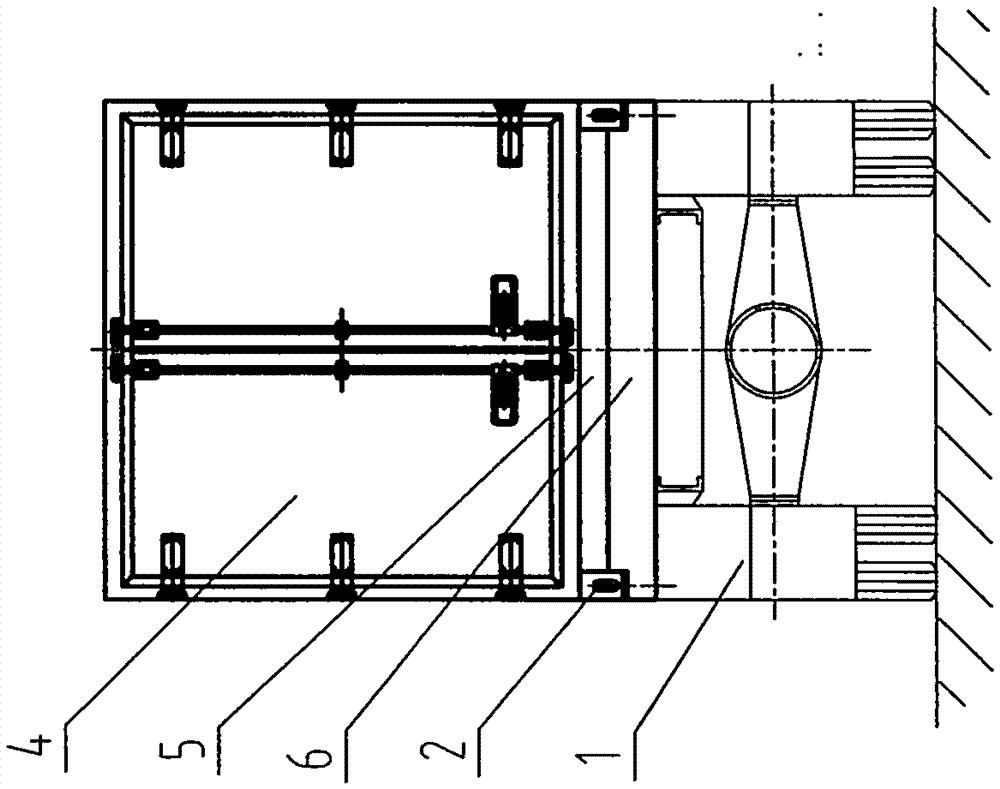

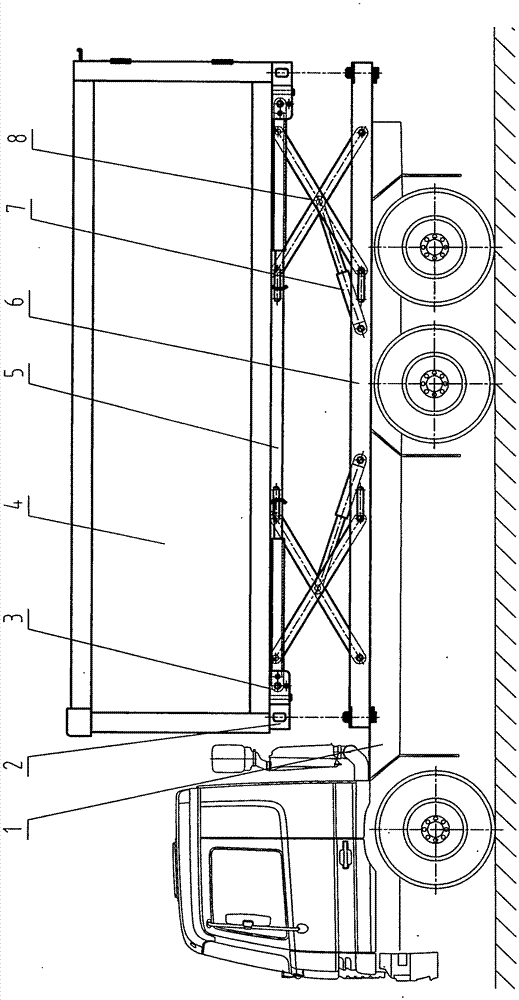

[0017] A box-type box truck is composed of three parts: a car chassis, a lifting mechanism and a car box body. The lifting mechanism is arranged in the middle of the car chassis 1 and the car box body 4. The girder is fixedly connected, and the upper frame 5 of the lifting mechanism is supported on the bottom of the car box body 4, and the two can be disengaged. In the middle of the lower frame 6 and the upper frame 5, two sets of lifting scissors 8 and power cylinders 7 are arranged. Between the box body 4 and the lower frame 6, two different states that can be combined and locked or separated and disengaged can be realized through the container locks 2 arranged on the four corners of the frame. Each container lock 2 has a lock hole seat and a lock pin seat. Composed of two parts, the keyhole seats of each container lock 2 are installed on the four corners below the car body 4 respectively, and the lock pin seats of each container lock 2 are installed on the four corners of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com