Novel cloth wind-up device

A new type of technology for rolling cloth, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of difficult to take out the reel, low production efficiency, troublesome opening and closing, etc., to save materials, improve production efficiency, The effect of saving lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

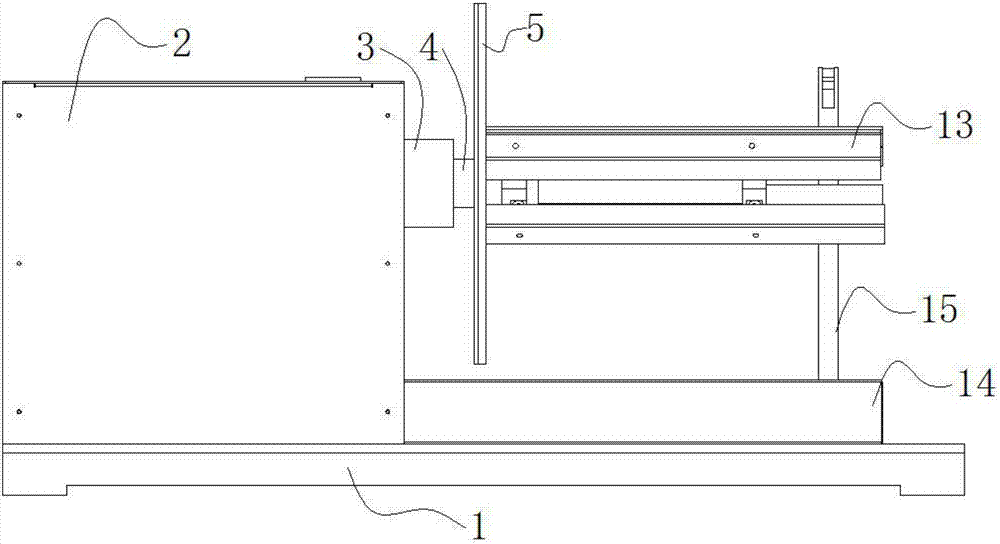

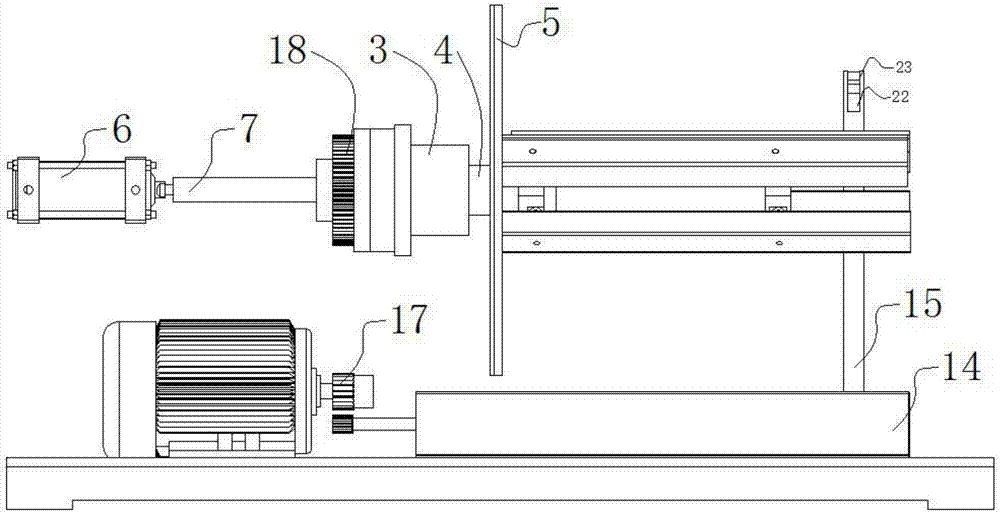

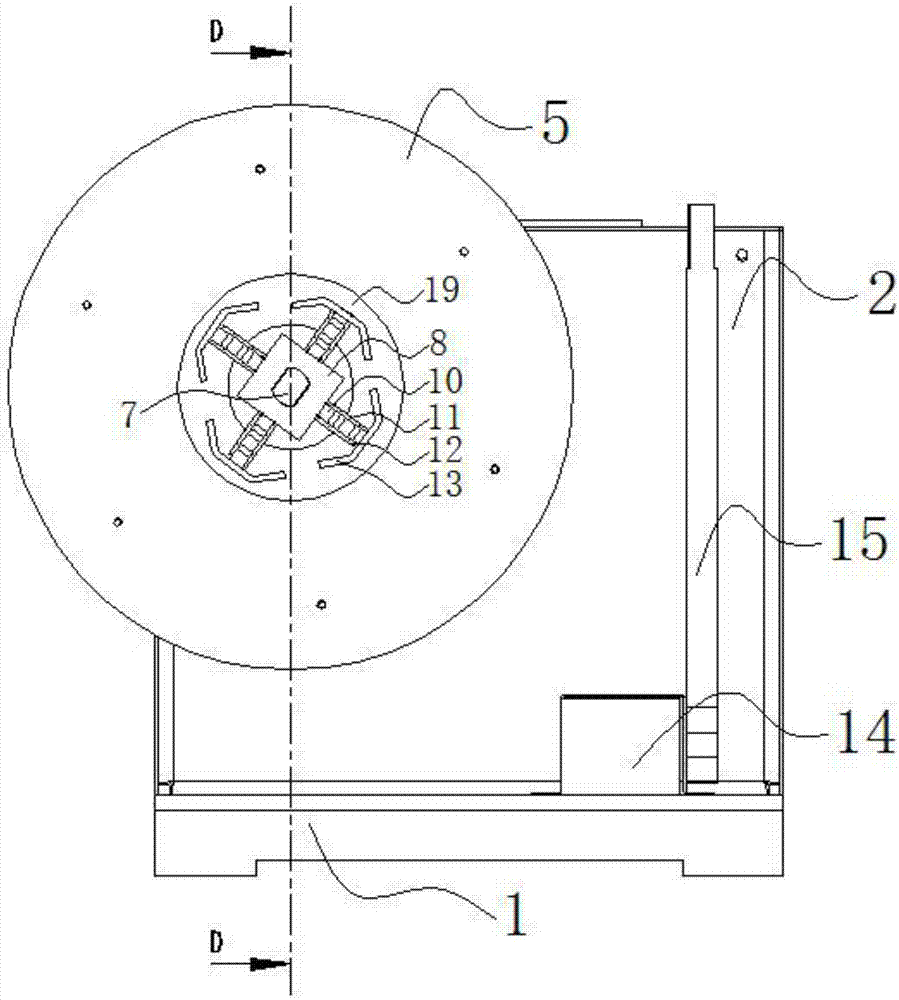

[0037] Such as Figure 1 to Figure 6 As shown, a new type of cloth rolling device includes a base 1 and a box body 2 located on the side above the base, and also includes a rotating mechanism and a bending plate telescopic mechanism,

[0038] The rotating mechanism includes a shaft sleeve 3 fixed on one side of the box body 2, a rotating shaft 4 disposed in the shaft sleeve 3 and slidingly connected with the shaft sleeve 3, a turntable 5 fixedly connected to the outer surface of the rotating shaft 4, and fixed to the side of the rotating shaft 4. The connected second joint seat 9, the outer shaft 20 fixedly connected to the other side of the second joint seat 9; also includes a motor 17 located inside the box body 2, and a gear shaft 18 connected to the output shaft of the motor 17 through a synchronous belt , the gear shaft 18 is coaxial and fixedly connected to the sleeve 3;

[0039] The bending telescopic mechanism includes a cylinder 6 fixed inside the box body 2, a slidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com