Hydraulic lift for disassembling and assembling large arm of high-altitude operation device

A high-altitude operation and lift technology, which is applied in the direction of lifting equipment safety devices, lifting frames, lifting devices, etc., can solve the problem that hydraulic lifts cannot adapt to hydraulic self-locking and supporting equipment, and achieve fast connection, high safety performance, and convenient movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

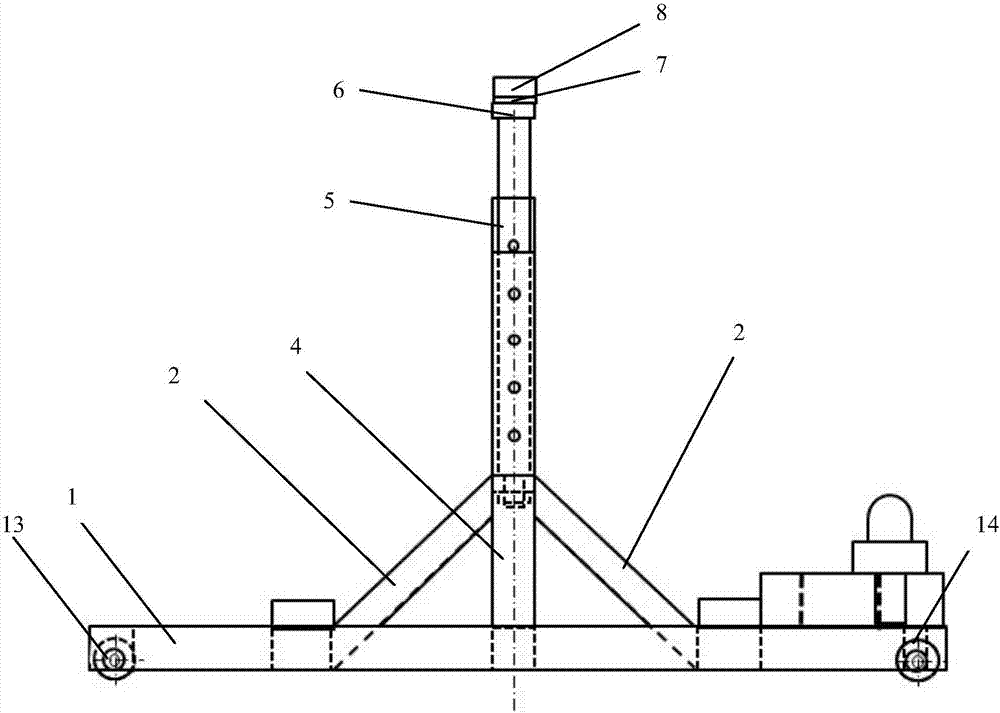

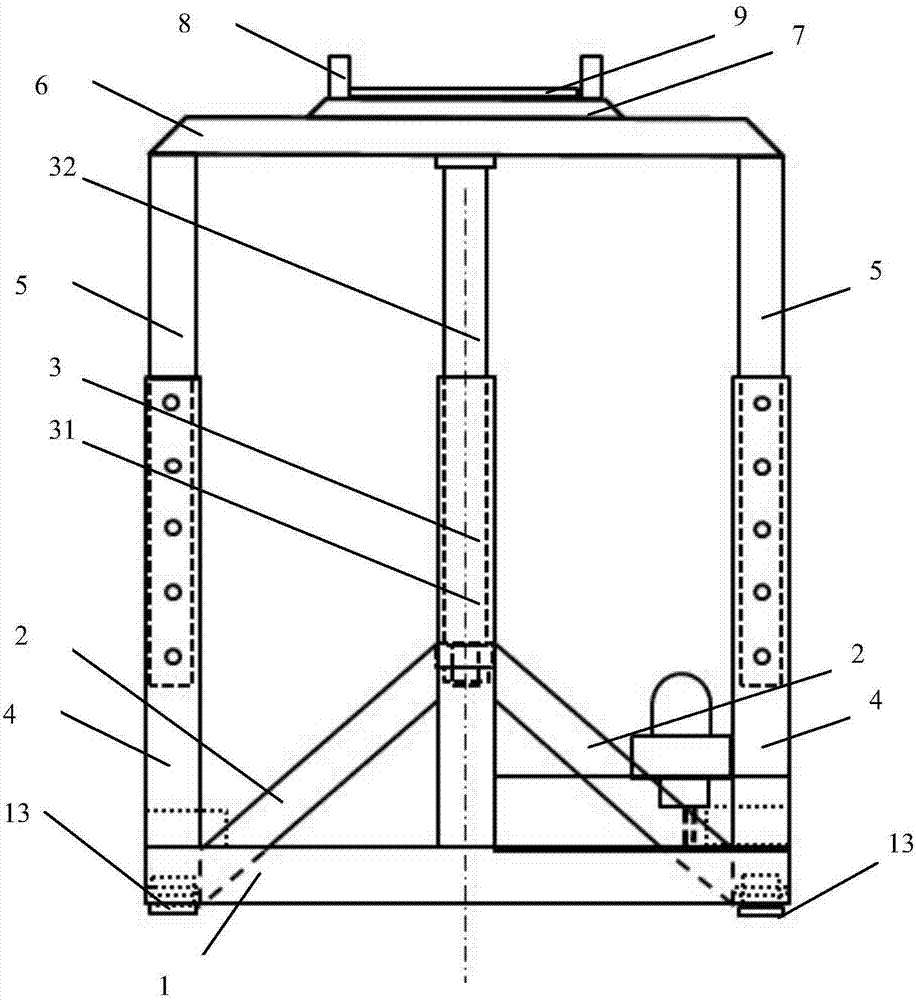

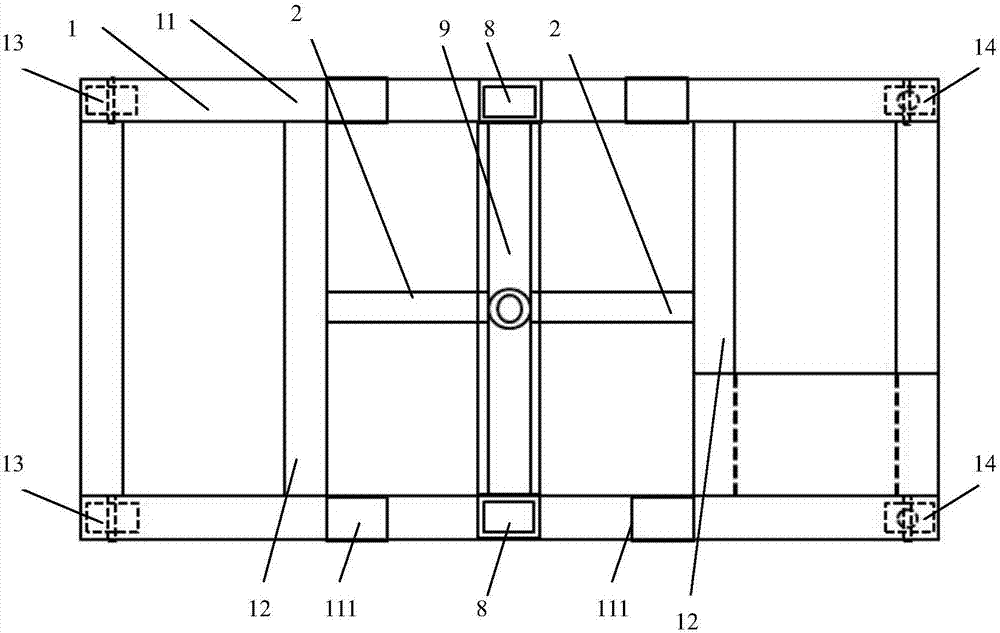

[0029] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 3 As shown, the base 1 includes a rectangular frame body 11 and two horizontal bars 12, the two ends of the two horizontal bars 12 are respectively fixedly connected to the inner sides of the two sides of the rectangular frame body 11, and the two horizontal bars 12 are arranged in parallel.

[0030] In a further embodiment of the present invention, the lower ends of the two diagonal braces 2 are respectively fixedly connected with the two sides of the rectangular frame body 11 , and the lower ends of the other two diagonal braces 2 are fixedly connected with the two horizontal bars 12 respectively.

[0031] In a further embodiment of the present invention, the lower ends of the two outer supports 4 are respectively fixedly connected to the two sides of the rectangular frame body 11 .

[0032] In a further embodiment of the present invention, the rectangular frame body 11 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap