A method for preparing titanium dioxide seed crystals by using chlorinated waste acid

A technology for chlorinating waste acid and titanium dioxide, which is applied in the direction of chemical instruments and methods, titanium dioxide, chlorine/hydrogen chloride, etc., can solve the problems of inability to be recycled and waste of waste hydrochloric acid, and achieve the effect of reducing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

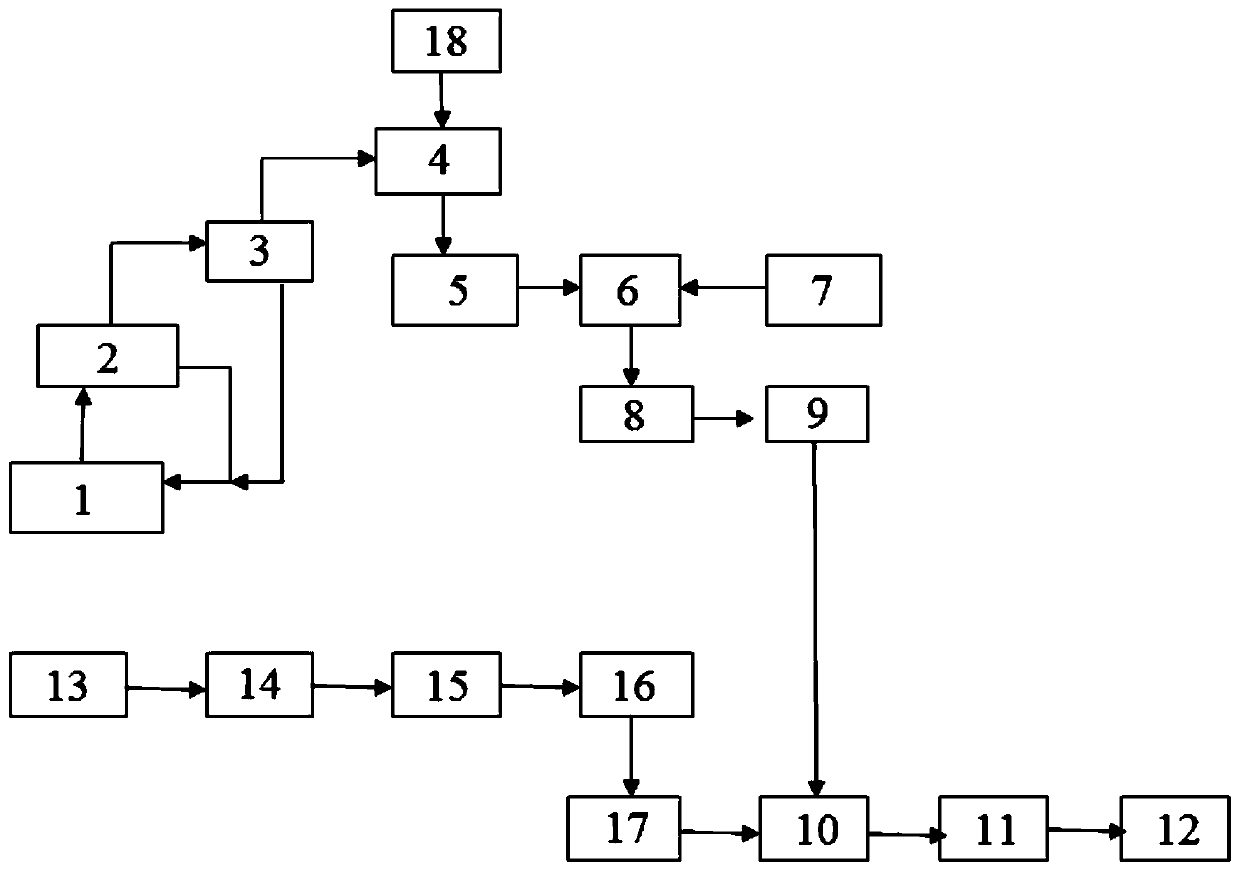

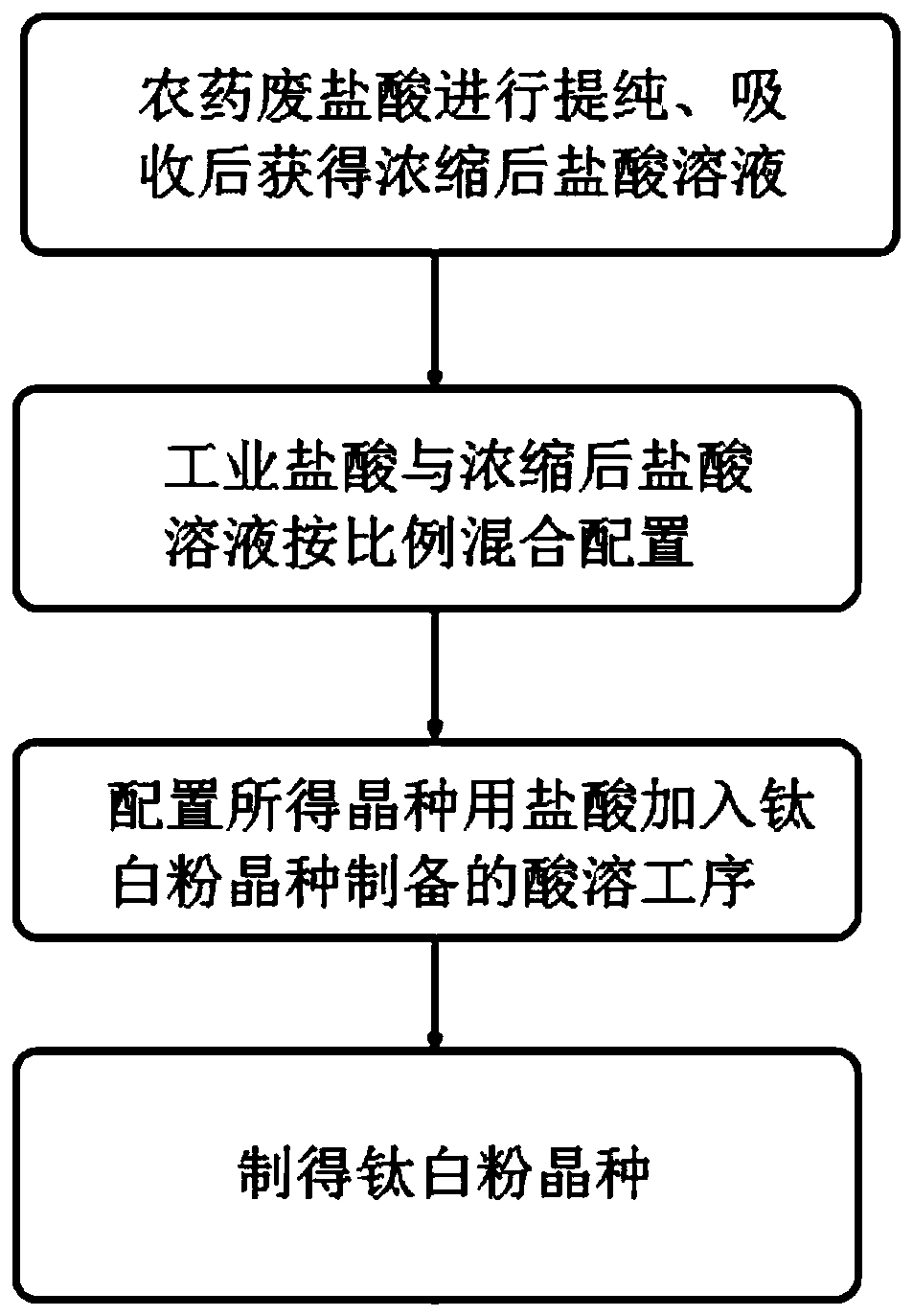

[0047] In this embodiment, a production system for preparing titanium dioxide seed crystals from pesticide waste hydrochloric acid concentrates the pesticide waste acid, including purification and absorption, which not only removes impurities in the waste hydrochloric acid, but also increases its concentration to reach titanium dioxide crystals. This kind of preparation conditions can not only reduce the cost of waste hydrochloric acid treatment in pesticide factories, but also reduce the cost of purchasing industrial hydrochloric acid for titanium dioxide manufacturers. The principle of waste hydrochloric acid concentration is: by adjusting the evaporation pressure, the hydrogen chloride gas is transferred from the liquid phase to the gas phase.

[0048] combine figure 1 The production system of this embodiment specifically includes a waste hydrochloric acid storage tank 1, an evaporator 2, a gas-liquid separator 3, an absorption tower 4, a hydrochloric acid storage tank 5, a...

Embodiment 2

[0074] A production system for preparing titanium dioxide seed crystals using pesticide waste hydrochloric acid in this embodiment is basically the same as in Example 1. The specific process of preparing titanium dioxide crystal seeds using pesticide waste hydrochloric acid in this embodiment is as follows:

[0075] Step 1: The waste hydrochloric acid storage tank 1 supplies waste hydrochloric acid to the evaporator 2 through the transfer pump, and the negative pressure of the evaporator 2 fluctuates between 350-360KPa.

[0076] Step 2, the evaporator 2 supplies the gas-liquid separator 3 with the mixed gas of HCl and water vapor; a small amount of dilute hydrochloric acid containing HCl at the bottom of the evaporator 2 is discharged to the waste hydrochloric acid storage tank 1 .

[0077] Step 3: After the gas-liquid separator 3 supplies steam, the absorption tower 4 is opened, the liquid in the gas-liquid separator 3 is separated, and transferred to the waste hydrochloric ac...

Embodiment 3

[0091] A production system for preparing titanium dioxide seed crystals using pesticide waste hydrochloric acid in this embodiment is basically the same as in Example 1. The specific process of preparing titanium dioxide crystal seeds using pesticide waste hydrochloric acid in this embodiment is as follows:

[0092] Step 1: The waste hydrochloric acid storage tank 1 supplies waste hydrochloric acid to the evaporator 2 through the transfer pump, and the negative pressure of the evaporator 2 fluctuates between 300-400KPa.

[0093] Step 2, the evaporator 2 supplies the gas-liquid separator 3 with the mixed gas of HCl and water vapor; a small amount of dilute hydrochloric acid containing HCl at the bottom of the evaporator 2 is discharged to the waste hydrochloric acid storage tank 1 .

[0094] Step 3: After the gas-liquid separator 3 supplies steam, the absorption tower 4 is opened, the liquid in the gas-liquid separator 3 is separated, and transferred to the waste hydrochloric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com