A smoothing machine with a flattening function

A troweling machine and functional technology, applied in the direction of construction, building structure, etc., can solve the problems of wall surface compaction, material feeding cannot be automated, and materials cannot be recycled, so as to realize material feeding automation and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

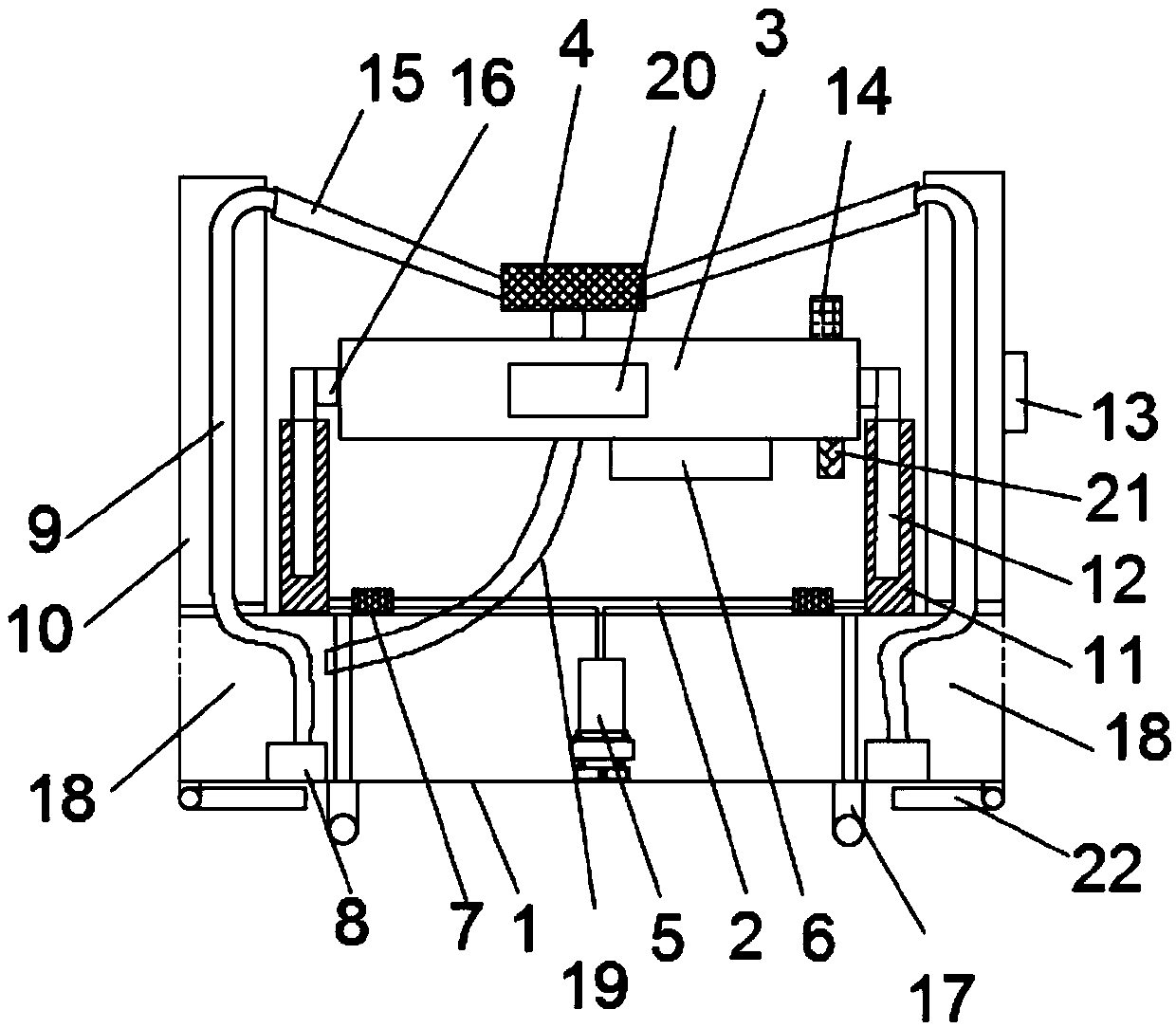

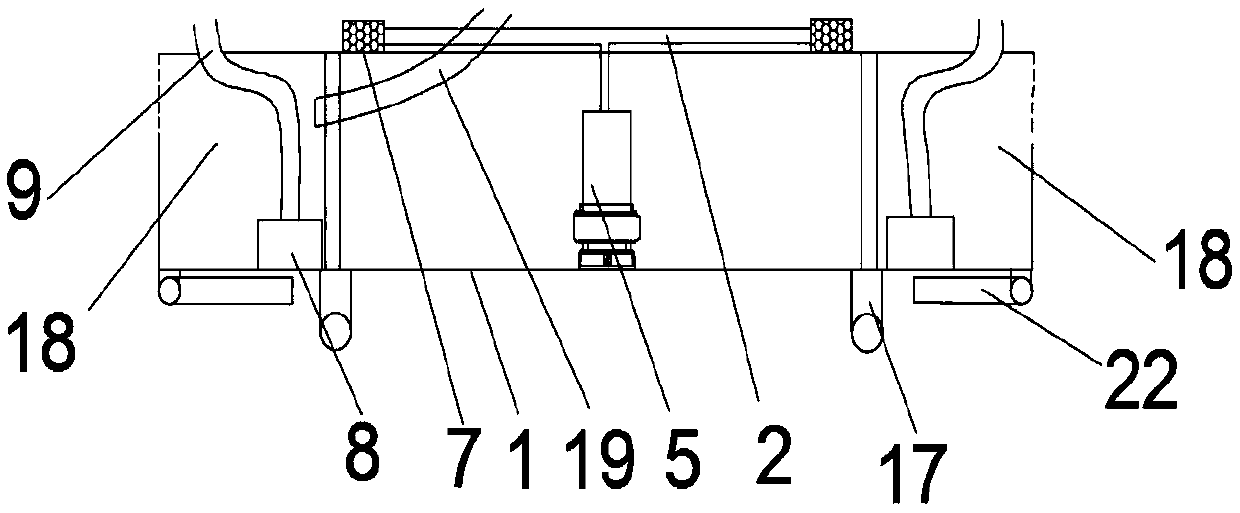

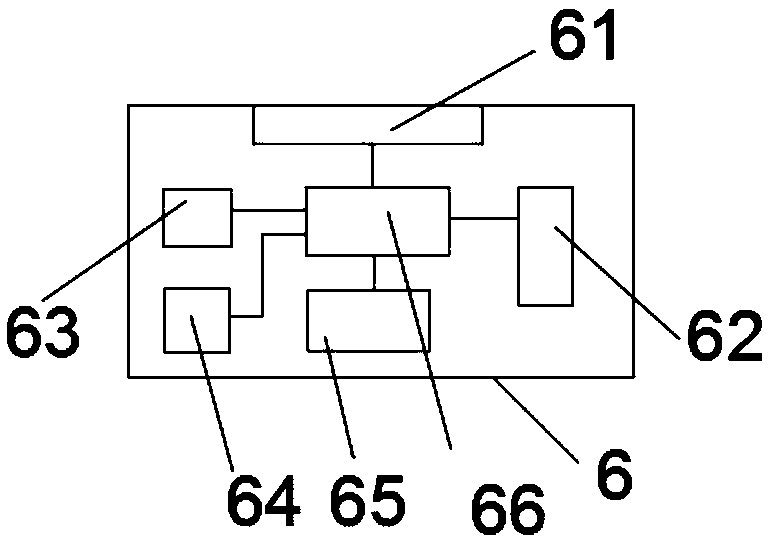

[0025] see Figure 1 to Figure 8 , the present invention provides a technical solution: a troweling machine with a flattening function, including a body 1, a flattening plate 3, a troweling push head 4, an air pressure machine 5 and a control box 6, and the left and right sides of the body 1 A pair of feed boxes 18 are provided, and an air compressor 5 is fixed in the middle of the body 1. The air compressor 5 is connected to a solenoid valve 7 at the upper end of the body 1 through an air guide pipe 2, and the solenoid valve 7 is provided on both sides of the upper end of the body 1. There is one, the other end of each solenoid valve 7 is connected to the hydraulic outer rod 11 through the air guide tube 2, the hydraulic rod can be controlled by the solenoid valve 7, and a pair of upper barrels 10 are arranged at the left and right ends of the outer upper end of the body 1, A main switch 13 is installed on the side wall of the upper material cylinder at the right end, and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com