a polishing machine

A troweling machine and engine technology, which is applied in the field of troweling machines, can solve problems such as increasing the labor intensity of operators, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

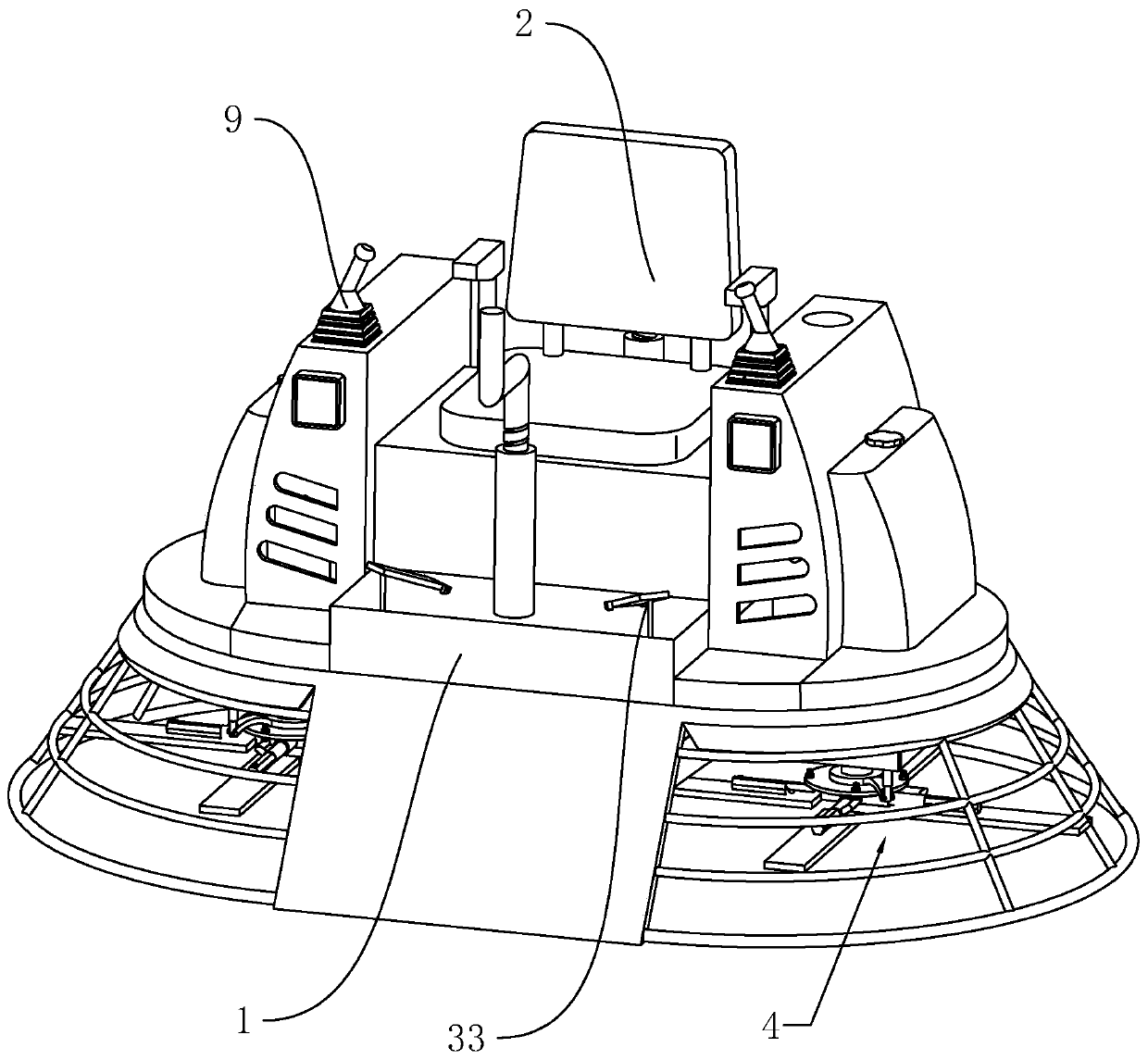

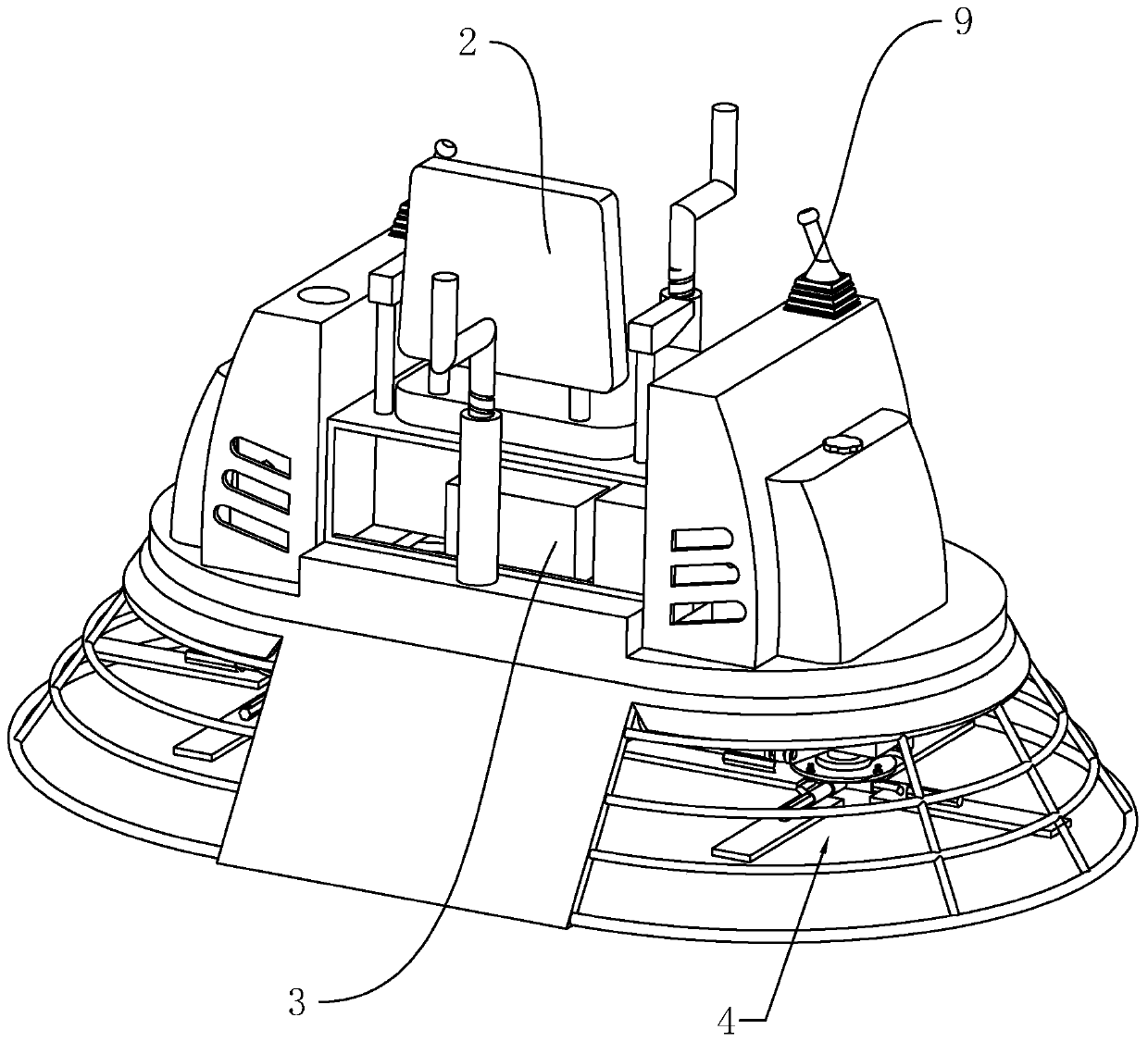

[0037] A trowel, combined with Figure 1-2 Shown, comprise cuboid chassis 1, a driver's seat 2 is fixedly installed in the middle position above chassis 1; A gasoline engine 3 is installed below chassis 1 and driver's seat 2; The midline of 2 is axially symmetrically provided with a wiper mechanism 4, and the engine 3 provides power for the wiper mechanism 4 to continuously rotate so as to achieve a smoothing effect on the ground.

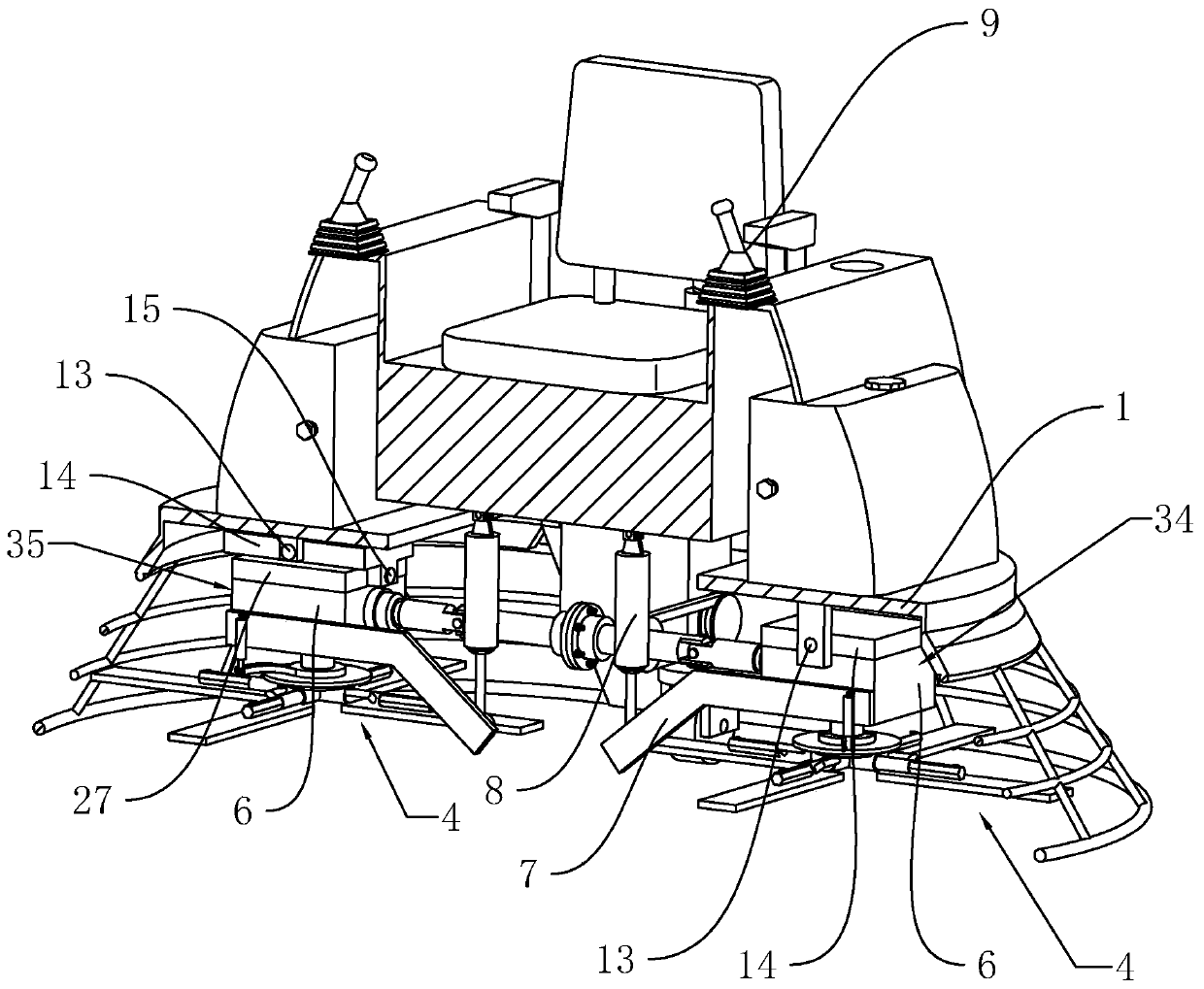

[0038] refer to image 3 As shown, a one-way installation assembly 34 and a two-way installation assembly 35 are respectively provided on both sides of the chassis 1 corresponding to the two wiper mechanisms 4; the one-way installation assembly 34 includes a And the axial direction is perpendicular to the straight-running rotating shaft 13 of two wiping mechanism 4 connecting lines, on the straight-running rotating shaft 13 radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com