Hydro-mechanical composite stepless transmission device of loader

A hydraulic machinery, stepless transmission technology, applied in transmission, fluid transmission, mechanical equipment, etc., can solve the problems of high power, low efficiency, discontinuous speed of hydraulic components, etc., to simplify design, reduce noise, The effect of improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

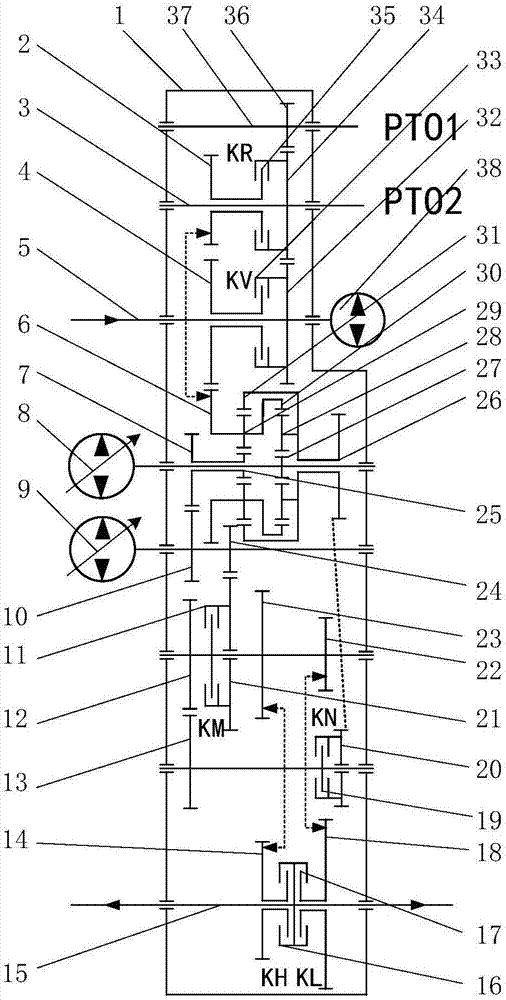

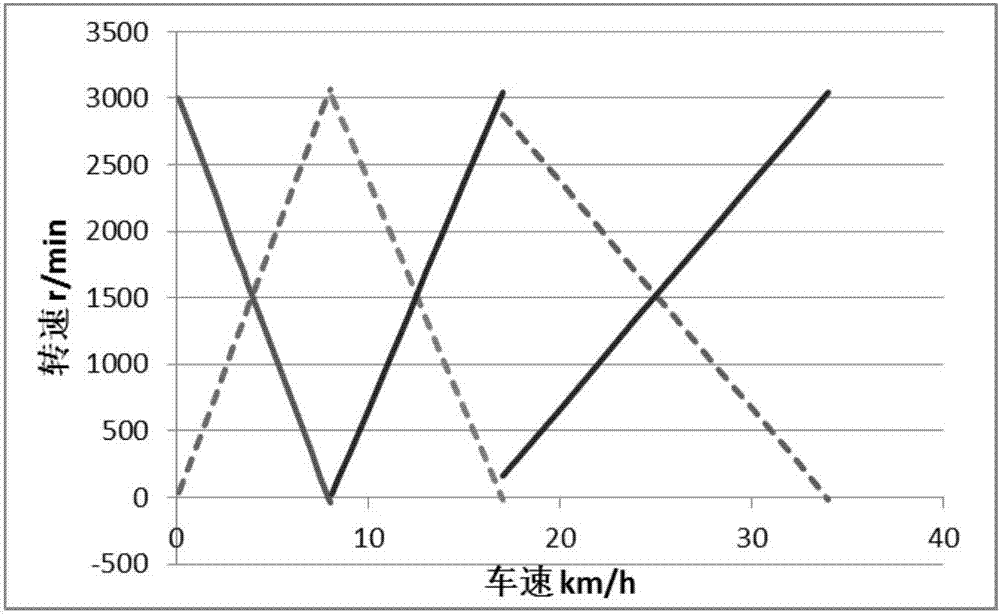

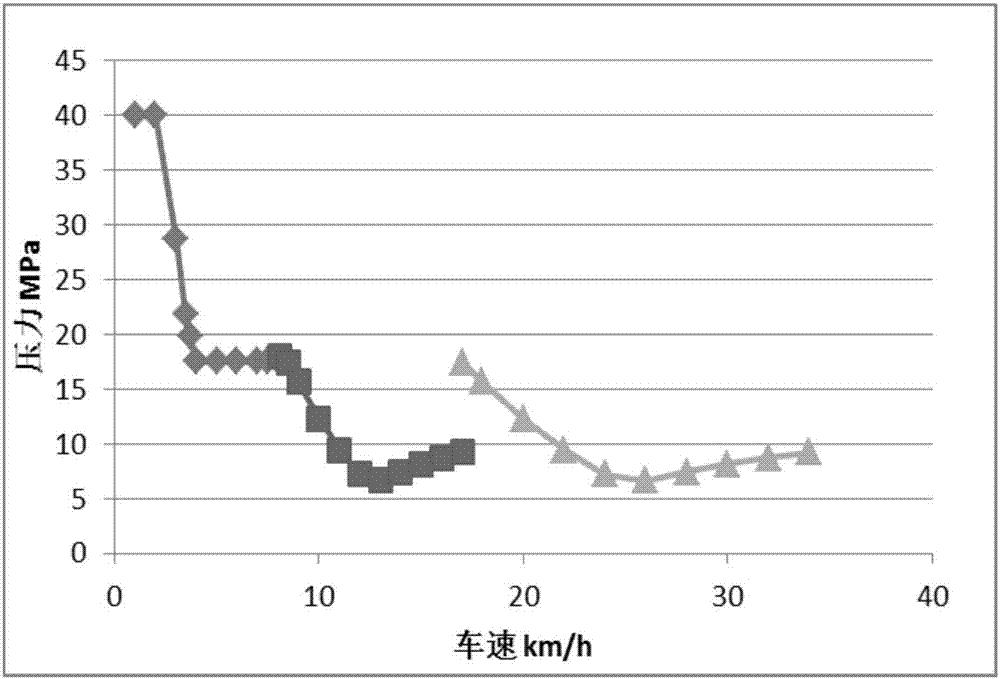

[0044] This embodiment provides a three-stage hydraulic-mechanical composite stepless transmission device for a loader, which includes three hydraulic-mechanical sections. As for the shifting gearbox, the invention can greatly improve the transmission efficiency of the transmission device, and can make the engine work in the economic speed range, and reduce the fuel consumption and noise level of the loader. The engine power is output to the front and rear axles of the loader after passing through the hydromechanical compound stepless transmission device.

[0045] Such as figure 1 As shown, the stepless transmission device includes: hydraulic speed regulation circuit, CR-CR diversion and confluence mechanism, fixed-axis gear transmission mechanism of hydraulic machinery stage I, fixed-axis gear transmission mechanism of hydraulic machinery stage II, fixed-axis gear transmission mechanism of hydraulic machinery stage III Institutions and Inverted Institutions.

[0046] The hy...

Embodiment 2

[0066] Such as Image 6 As shown, this embodiment and figure 1 Compared with the shown embodiment 1, the design of the high and low gears is cancelled, thereby reducing the number of gear engagements and increasing the efficiency. That is, the clutch KH16, the clutch KL17, the gear 18, the gear E12 and the gear K22 are omitted. with the said figure 1 Compared with the embodiment, the working section only includes the hydraulic machinery section I and the hydraulic machinery section II; the retreat is two hydraulic machinery sections.

[0067] The specific transmission diagram of the transmission device in this embodiment is as follows: Image 6 As shown, it includes: hydraulic speed regulating circuit, CR-CR sub-convergence mechanism, fixed-axis gear transmission mechanism of hydraulic machinery section I, fixed-axis gear transmission mechanism of hydraulic machinery section II, and forward and reverse mechanism. The engine power is output to the front and rear axles of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com