Safety valve and air brake system

A safety valve and valve body technology, which is applied in safety valves, valve devices, balance valves, etc., can solve problems such as difficulty in opening and closing pressure control, leakage of exhaust valves, scratches on grinding surfaces, etc., and achieve improved sealing and braking effects , Facilitate pipeline pressure and improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

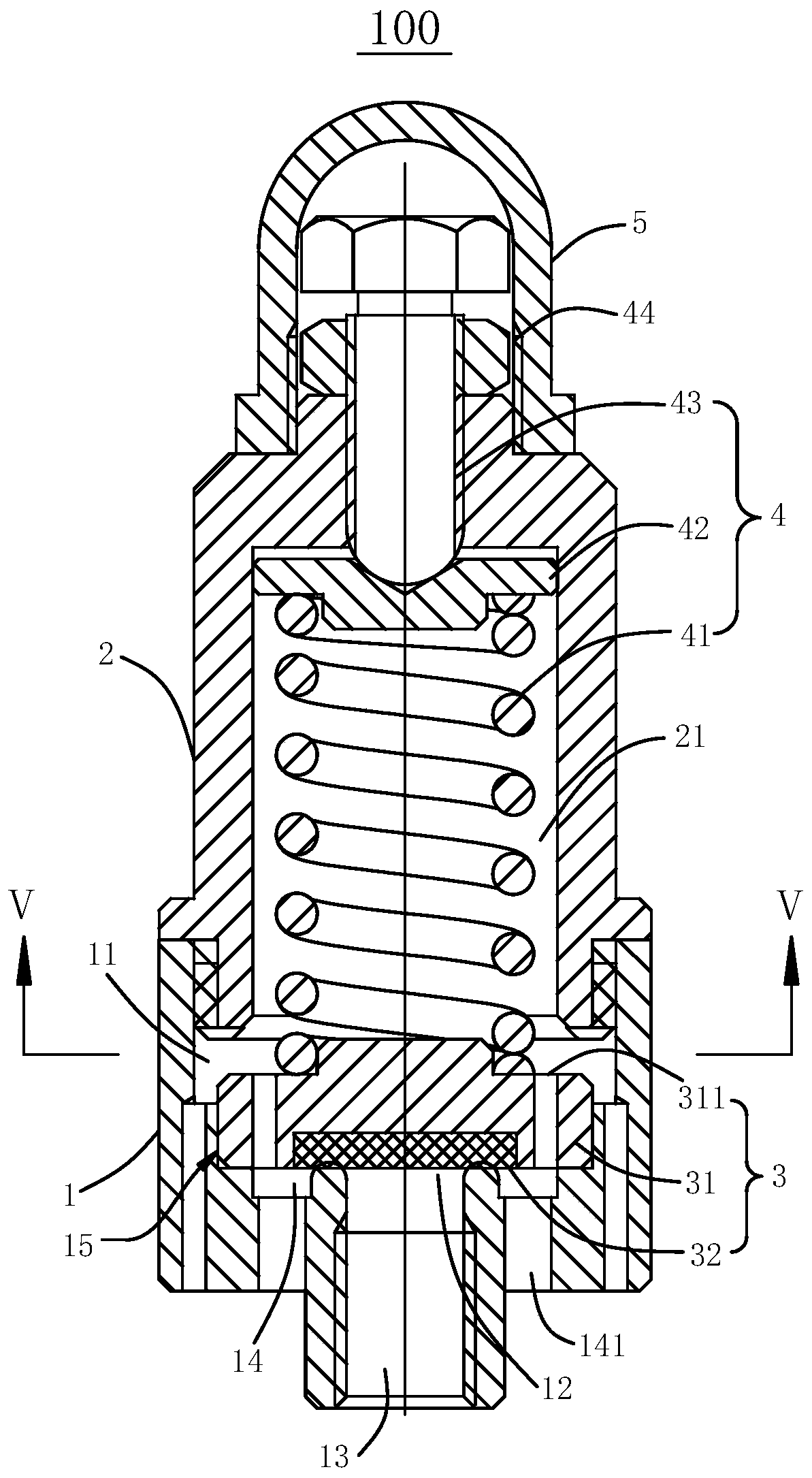

[0033] Please refer to figure 1 , this embodiment provides a safety valve 100 , including a valve body 1 , a spring box 2 , a sandwich valve 3 and a return assembly 4 .

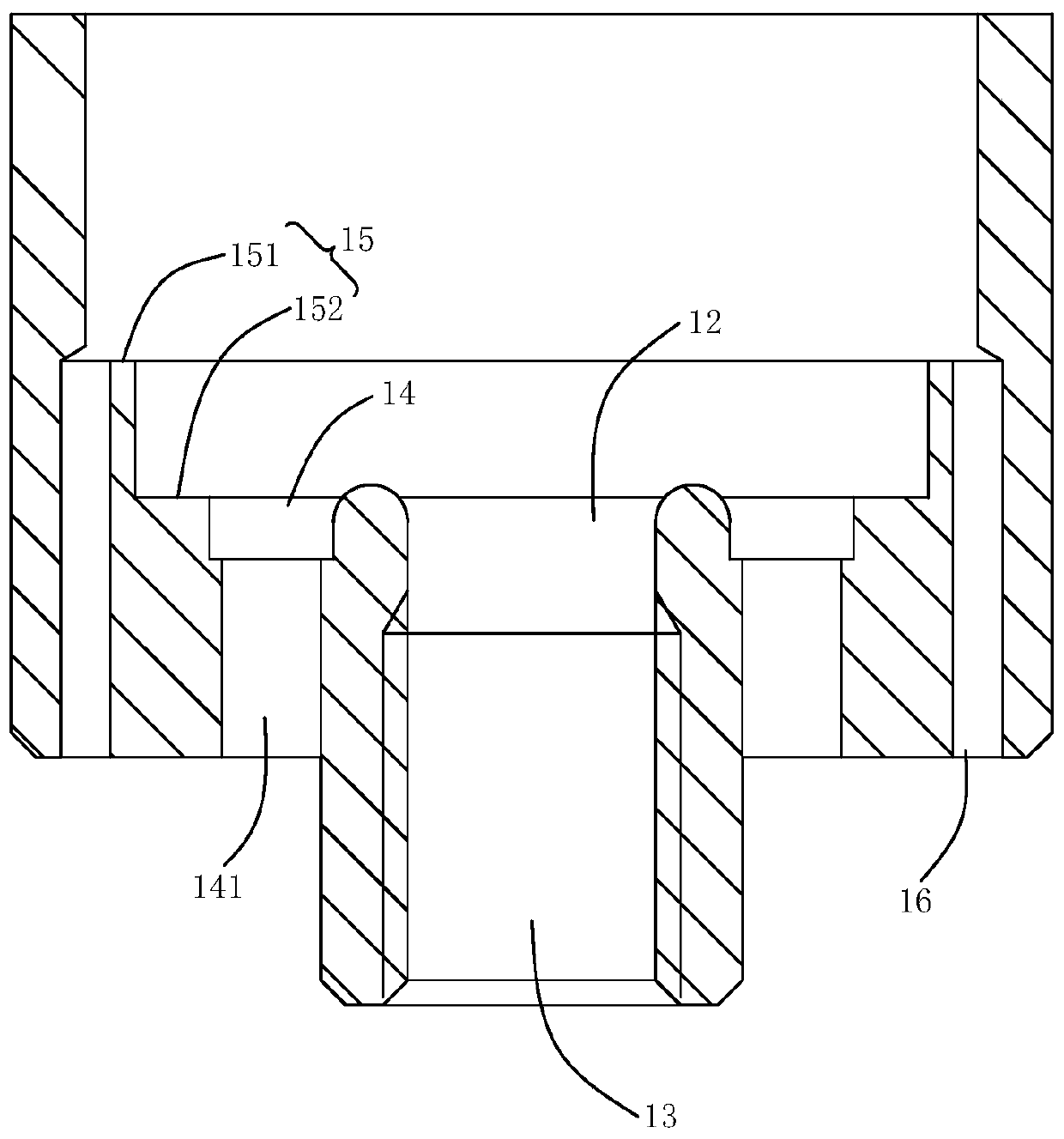

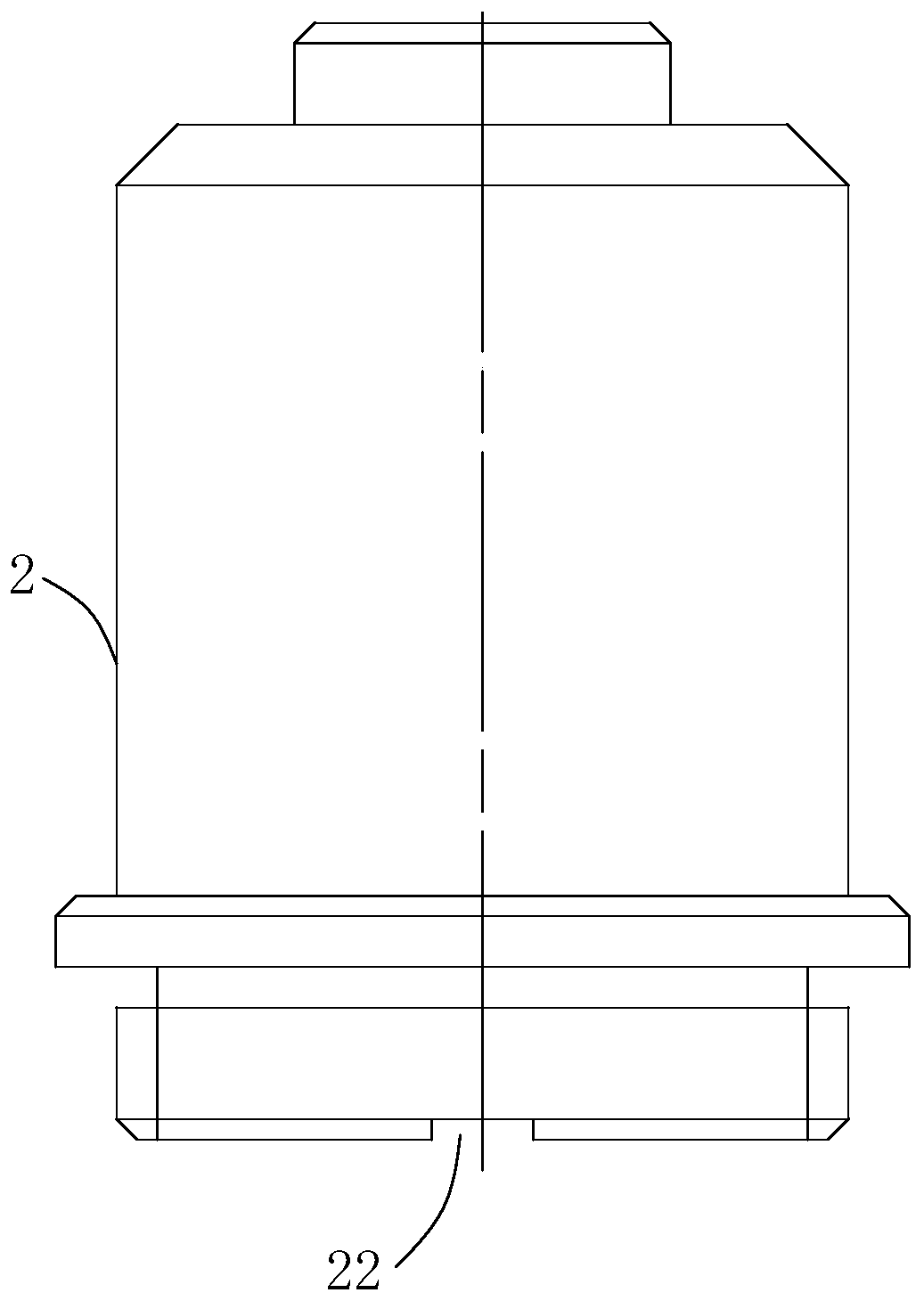

[0034] In this embodiment, the valve body 1 cooperates with the spring box 2 to form an active cavity 11 inside the two, and the valve port 12 communicates with the active cavity 11. The sandwich valve 3 is slidably arranged in the active cavity 11. The sandwich valve 3 includes a valve The core 31 and the rubber gasket 32, the rubber gasket 32 is embedded in the valve core 31, the spring box 2 is provided with an accommodating chamber 21 communicating with the movable chamber 11, the return assembly 4 is slidably arranged in the accommodating chamber 21, and the return assembly The two ends of 4 are respectively connected with the spring box 2 and the valve core 31, and the return component 4 applies the force applied to the valve core 31 to move toward the valve port 12, and is used to drive the rubber ga...

no. 2 example

[0063] This embodiment provides an air braking system, including the safety valve 100 provided in the first embodiment.

[0064] In this embodiment, the air brake system, since the pipeline pressure is provided by compressed air, therefore, the setting of the safety valve 100 can improve the pressure control of the pipeline. The safety valve 100 has a good sealing and braking effect, can effectively protect the pressure of the pipeline, is convenient to adjust the pressure, and improves the control ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com