Suction pipe applicable to fracturing pump

A suction pipe, fracturing pump technology, applied in the direction of pipes, branch pipelines, pipes/pipe joints/pipe fittings, etc. Smooth discharge, balanced pressure, good for carrying sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the examples and specific implementation methods, but this should not be interpreted as the scope of the above-mentioned subject of the present invention being limited to the following examples, and all technologies realized based on the content of the present invention belong to the present invention protected range.

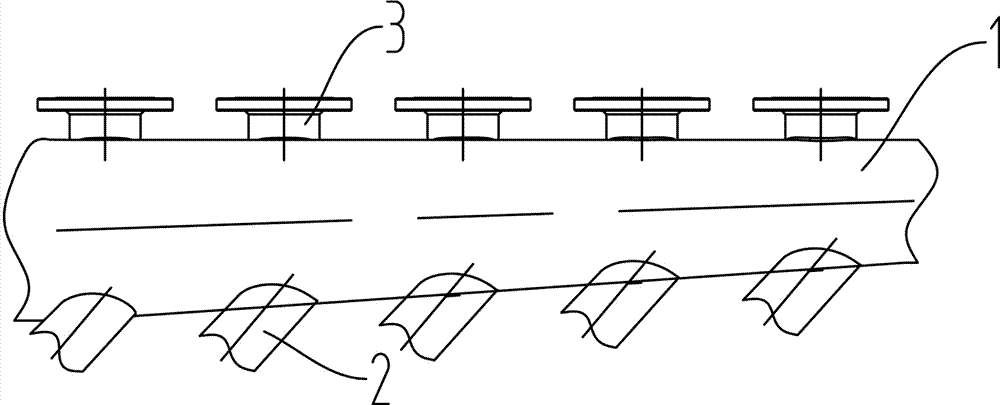

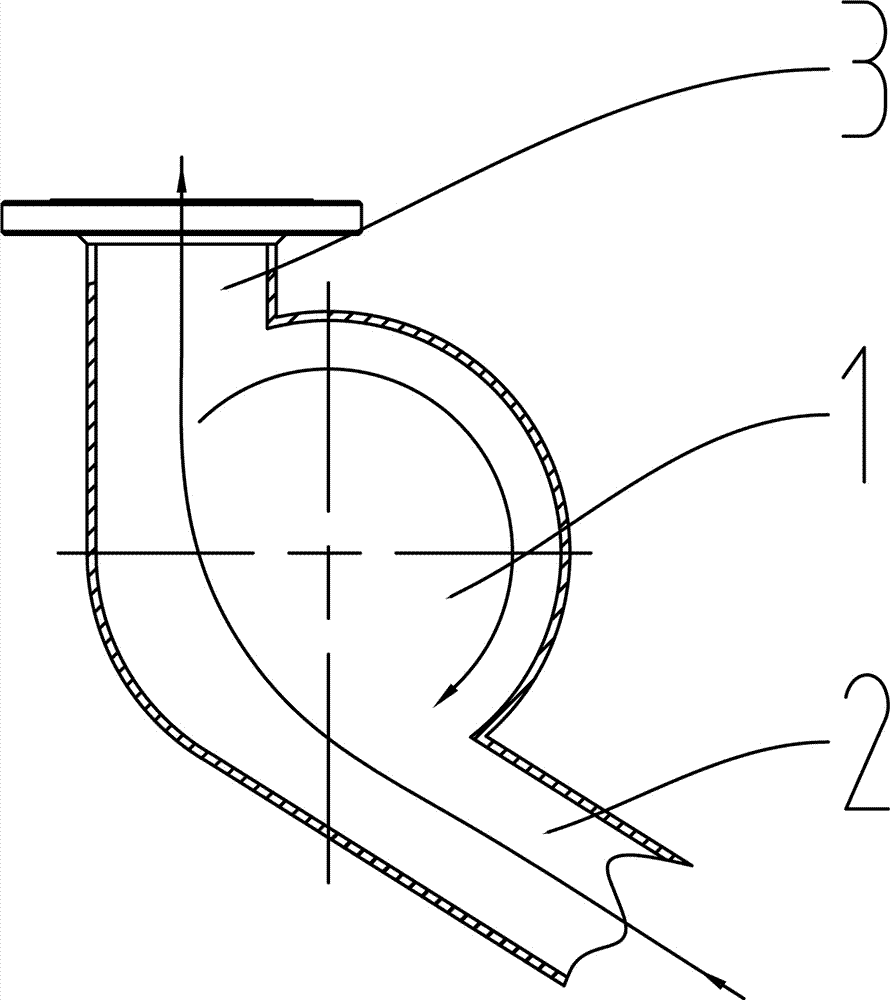

[0021] Such as figure 1 with figure 2 As shown, the present invention is made up of shunt pipe 1, inlet pipe 2 and discharge pipe 3, and the diameter of the liquid inlet end of shunt pipe 1 is greater than the diameter of liquid outflow end, and inlet pipe 2 is tangent to shunt pipe 1, and discharge pipe 3 and shunt pipe 1 also Tangent, the place where the inlet pipe 2 and the outlet pipe 3 are tangent to the shunt pipe 1 coincides. In other embodiments, the inlet pipe 2 and the outlet pipe 3 can also be approximately tangent to the shunt pipe, and the place where they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com