Permanent magnet motor

A technology of permanent magnet motors and permanent magnet poles, which is applied in the direction of magnetic circuits, synchronous machines, synchronous motors with stationary armatures and rotating magnets, etc., and can solve problems such as back EMF asymmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

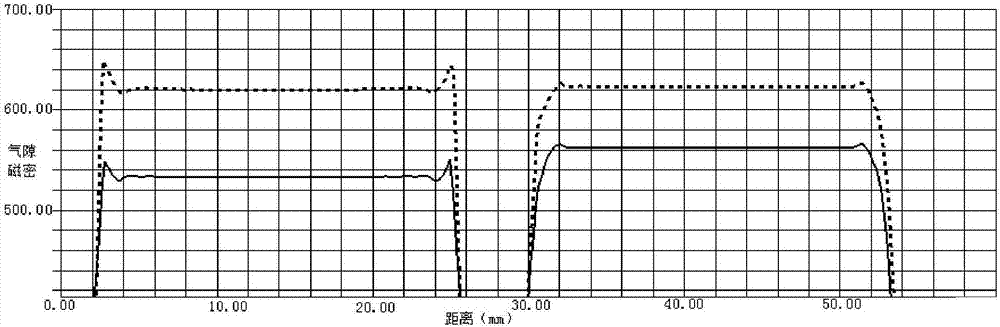

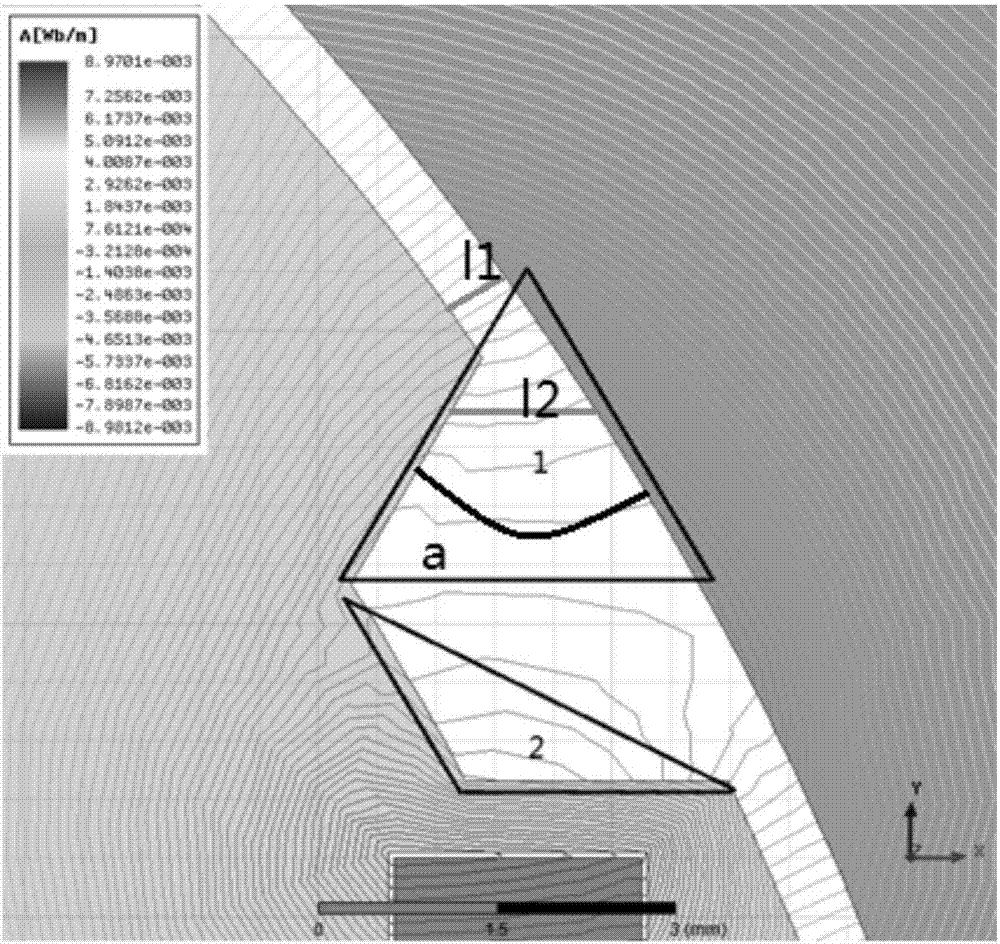

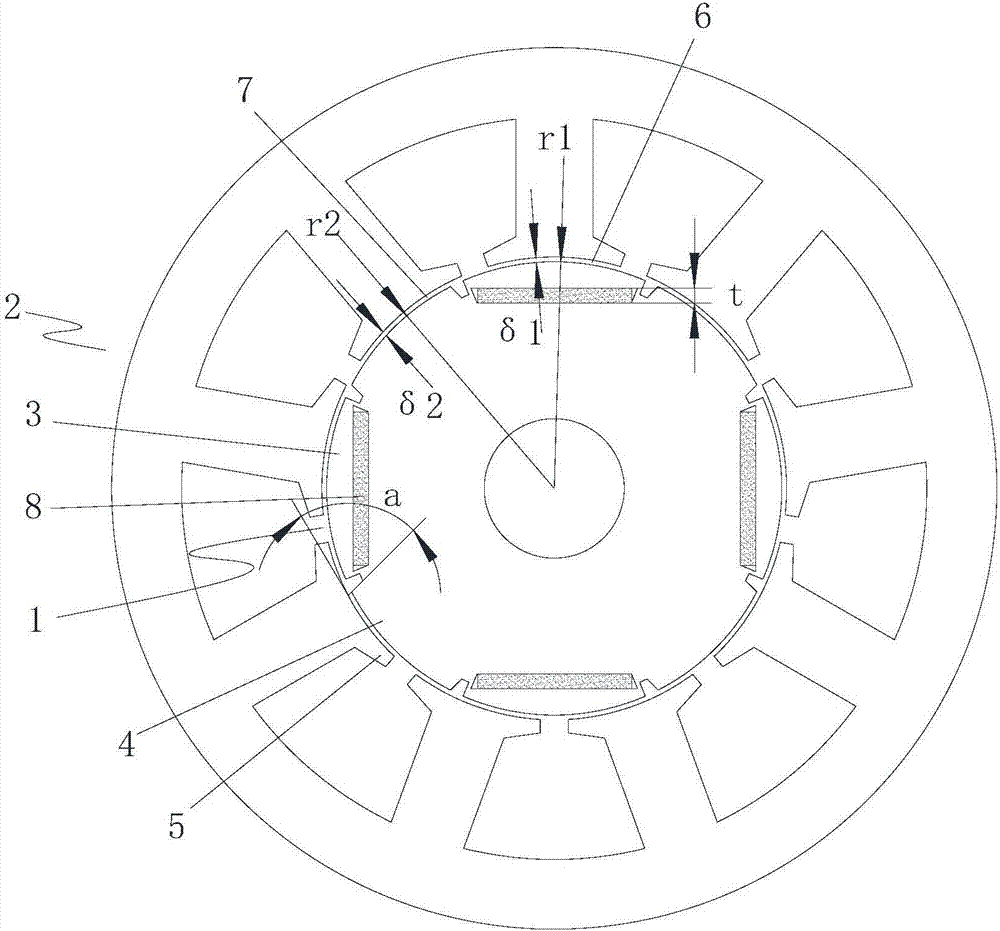

[0025] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present invention, the permanent magnet motor includes a rotor assembly 1 and a stator assembly 2, the rotor assembly 1 includes alternate poles 4 and permanent magnet poles 3 arranged alternately in the circumferential direction, and the stator assembly 2 includes a circumferential The stator teeth 5 arranged at intervals form a first air gap 6 between the inner peripheral side of the stator teeth 5 and the outer peripheral side of the permanent magnet pole 3, and the second air gap is formed between the inner circumference of the stator teeth 5 and the outer circumference of the alternating poles 4 7. The average thickness of the first air gap 6 is δ1, and the average thickness of the second air gap 7 is δ2, where 0.4≤δ2 / δ1≤0.9.

[0026] The rotor assembly 1 includes a rotor core, and the rotor core is formed by laminating sheets of soft magnetic material. The rotor iron core is pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap