Self-hot-and-cold tube heat dissipation power cabinet air duct automatic switching device

A heat dissipation power and automatic switching technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, cooling/ventilation/heating transformation, etc., can solve temperature rise, thermal breakdown of upper thyristor, and air duct Flexible switching and other issues to achieve the effect of increasing output current, improving heat dissipation efficiency, and simple and reliable air duct switching method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

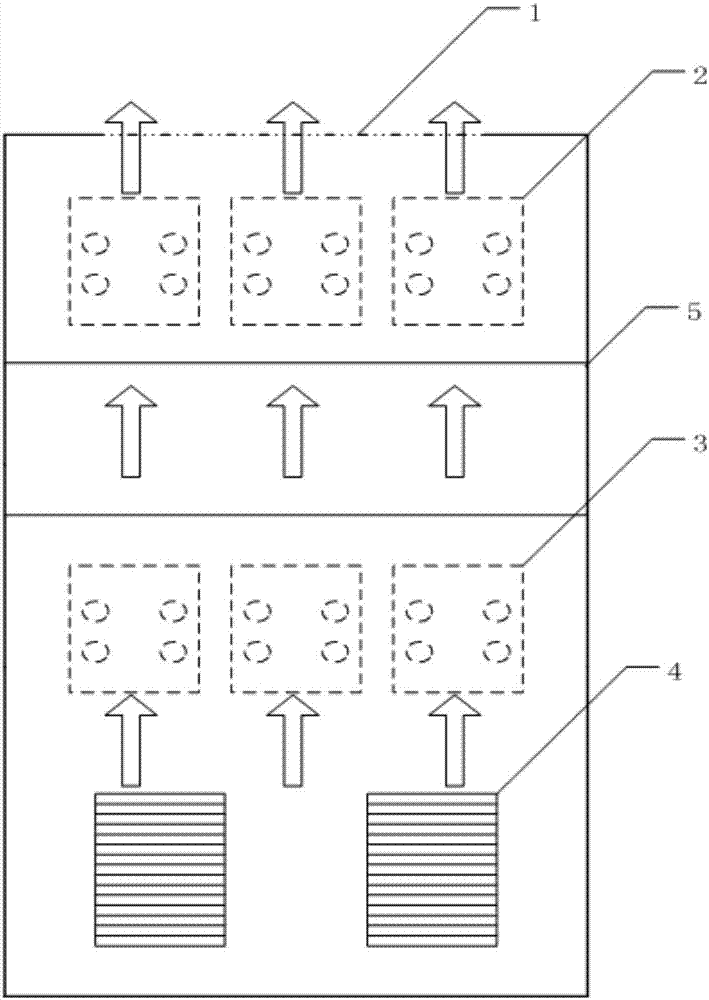

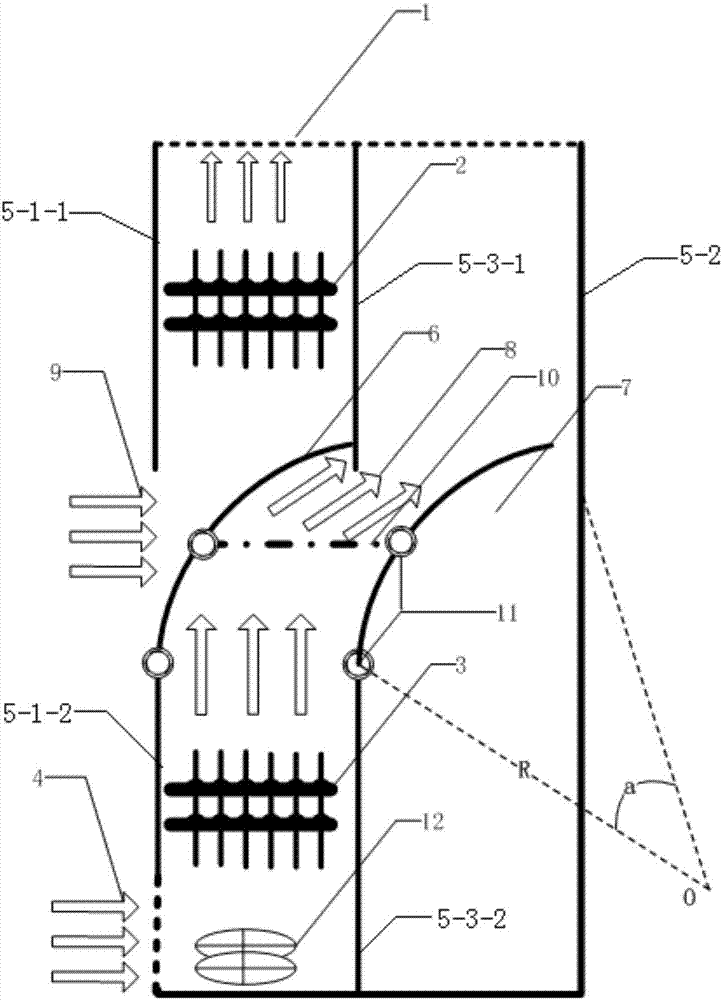

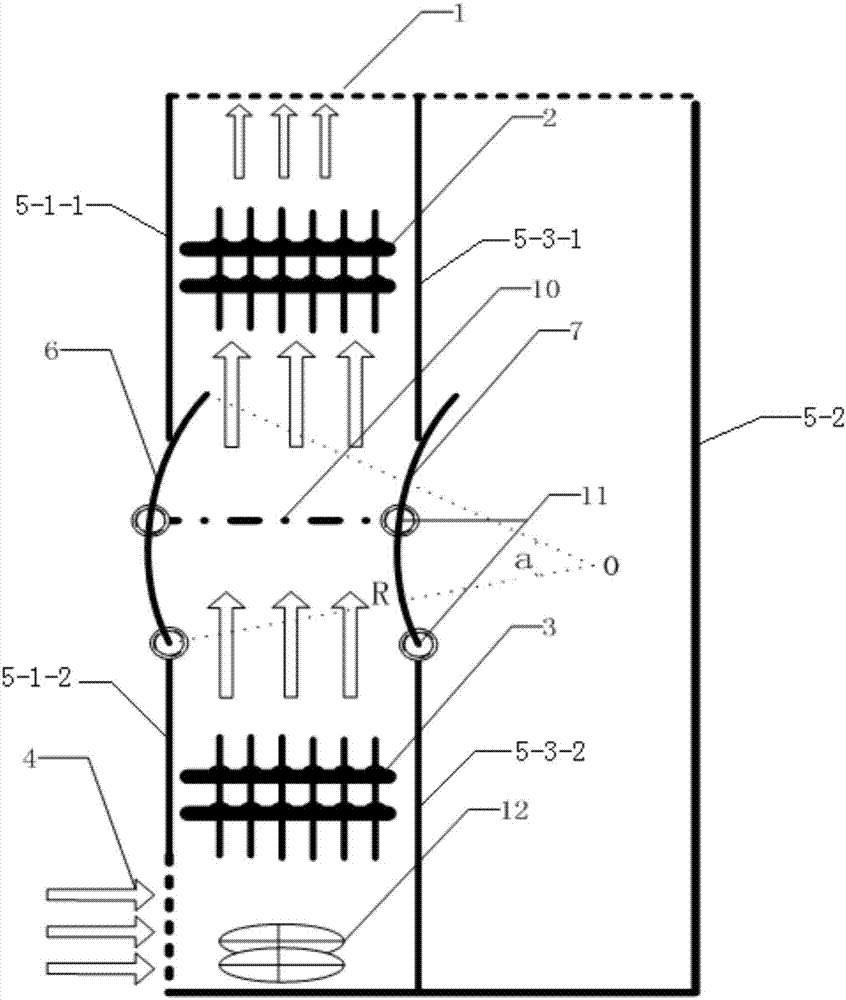

[0019] see figure 1 , a self-cooling heat pipe heat dissipation power cabinet air duct automatic switching device of the present invention includes a cabinet body 5, an upper heat pipe radiator 2, a lower heat pipe radiator 3, and a fan 12. The cabinet body 5 comprises a front plate, a back plate 5-2 and an intermediate plate between the front plate and the back plate 5-2; the front plate comprises an upper front plate 5-1-1 and a lower front plate 5-1-2, the lower The top of the front plate 5-1-2 is connected with a front wind deflector 6; the middle plate includes an upper middle plate 5-3-1 and a lower middle plate 5-3-2, and the top of the lower middle plate 5-3-2 is connected with a rear Air deflector 7; front air deflector 6 connects rear a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com