a garlic digger

A technology of garlic machines and racks, which is applied to excavators, digging harvesters, harvesters, etc., can solve the problems of high machine cost, poor economic benefits, and low harvesting level, and achieve simple structure, easy maintenance, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

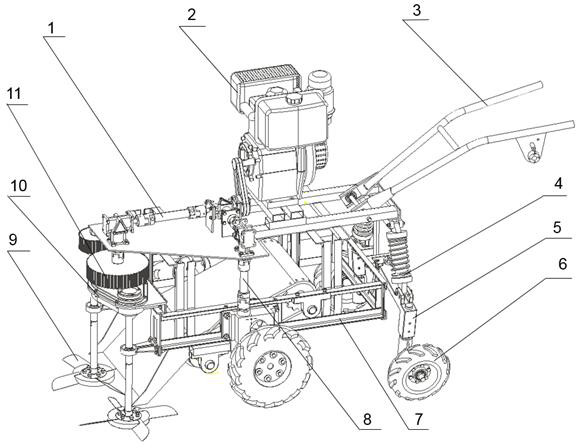

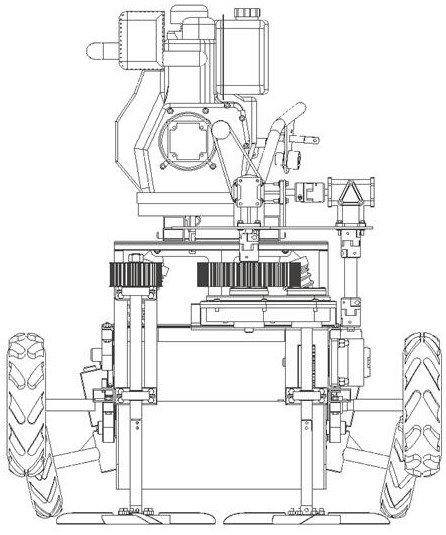

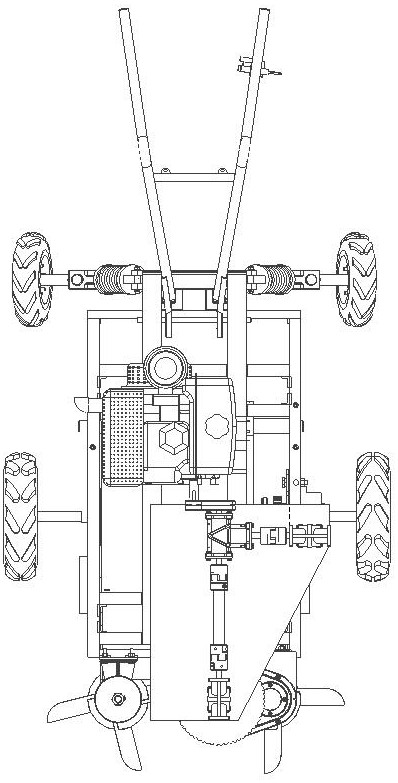

[0034] Embodiment 1: as Figure 1-11 As shown, a garlic digging machine includes a transmission device, an executive device, an armrest frame body 3, a floating suspension device 5 and a frame 7, and the transmission device includes an execution branch 1, an engine 2, a front wheel branch 8, Three-axis commutator 15 and transmission connecting plate 19, said executive device includes rotary garlic knife 9, gear box 10 and synchronous pulley 11, and said floating suspension device 5 includes suspension 4, rear wheel 6 and rear wheel shaft 32 ;

[0035] The execution branch 1 and the front wheel branch 8 are connected to the transmission connection plate 19, the engine 2 is connected to the frame 7, the transmission connection plate 19 is connected to the frame 7, and the engine 2 transmits power to the three-axis converter through the V-shaped pulley. Commutator 15, three-axis commutator 15 transmits power to execution branch 1, front wheel branch 8;

[0036] The execution br...

Embodiment 2

[0039] Embodiment 2: as Figure 1-11 As shown, a garlic digging machine includes a transmission device, an executive device, an armrest frame body 3, a floating suspension device 5 and a frame 7, and the transmission device includes an execution branch 1, an engine 2, a front wheel branch 8, Three-axis commutator 15 and transmission connecting plate 19, said executive device includes rotary garlic knife 9, gear box 10 and synchronous pulley 11, and said floating suspension device 5 includes suspension 4, rear wheel 6 and rear wheel shaft 32 ;

[0040] The execution branch 1 and the front wheel branch 8 are connected to the transmission connection plate 19, the engine 2 is connected to the frame 7, the transmission connection plate 19 is connected to the frame 7, and the engine 2 transmits power to the three-axis converter through the V-shaped pulley. Commutator 15, three-axis commutator 15 transmits power to execution branch 1, front wheel branch 8;

[0041] The execution br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com