A manufacturing method of yolk particles used for aquatic feed, the yolk particles, and the aquatic feed

A technology for manufacturing aquatic feed and granules, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc. It can solve the problems of deposition waste, inconvenient feeding of aquatic organisms such as fish and shrimp, easy loss or collapse, and achieve hardness and Good elasticity, good for feeding, good stability

Pending Publication Date: 2017-09-26

WUHAN POLYTECHNIC UNIVERSITY

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, boiled egg yolks are easy to lose or collapse when soaked in water, which is not convenient for aquatic organisms such as fish and shrimp to eat. This not only causes sediment waste, but also makes the water quality eutrophic, which in turn causes bacterial growth, resulting in mudd

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

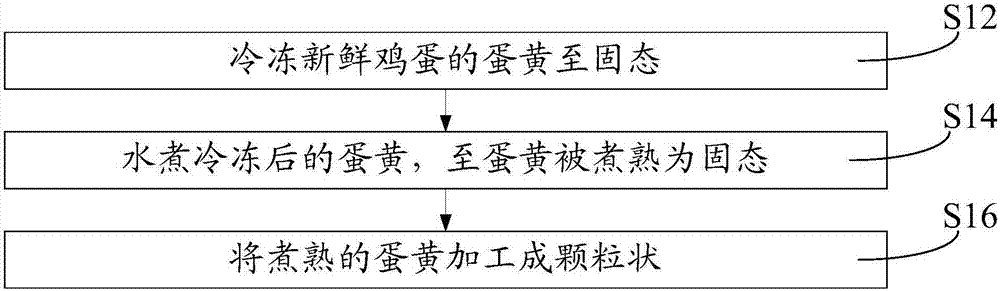

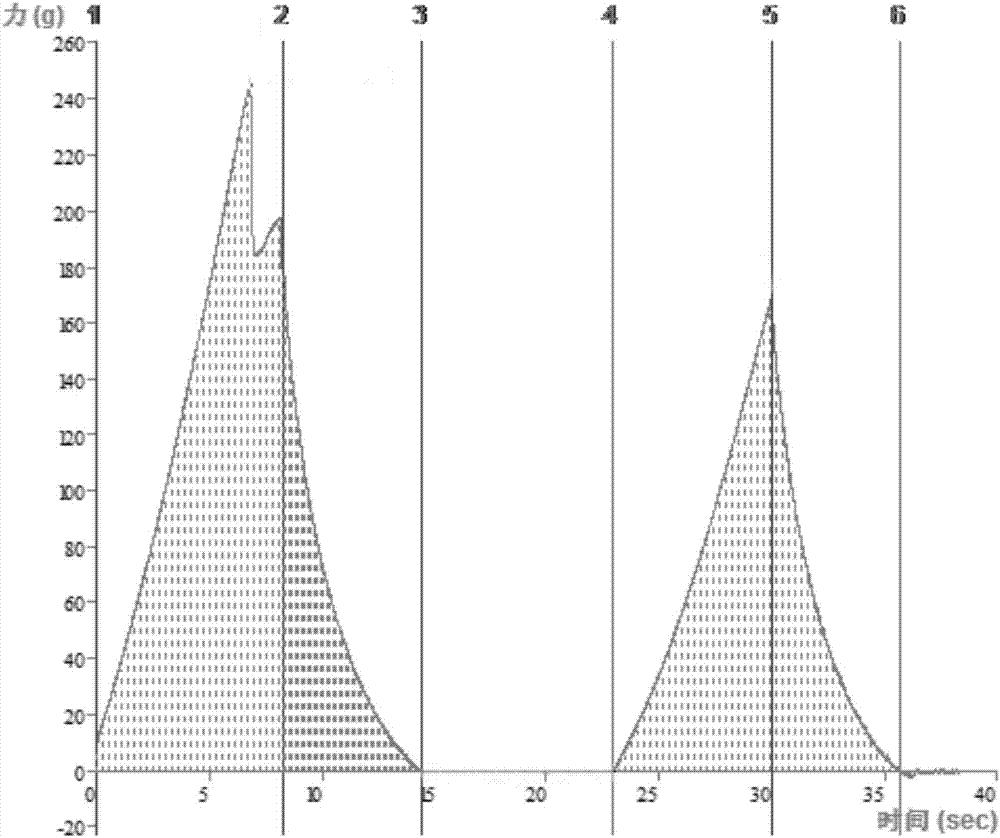

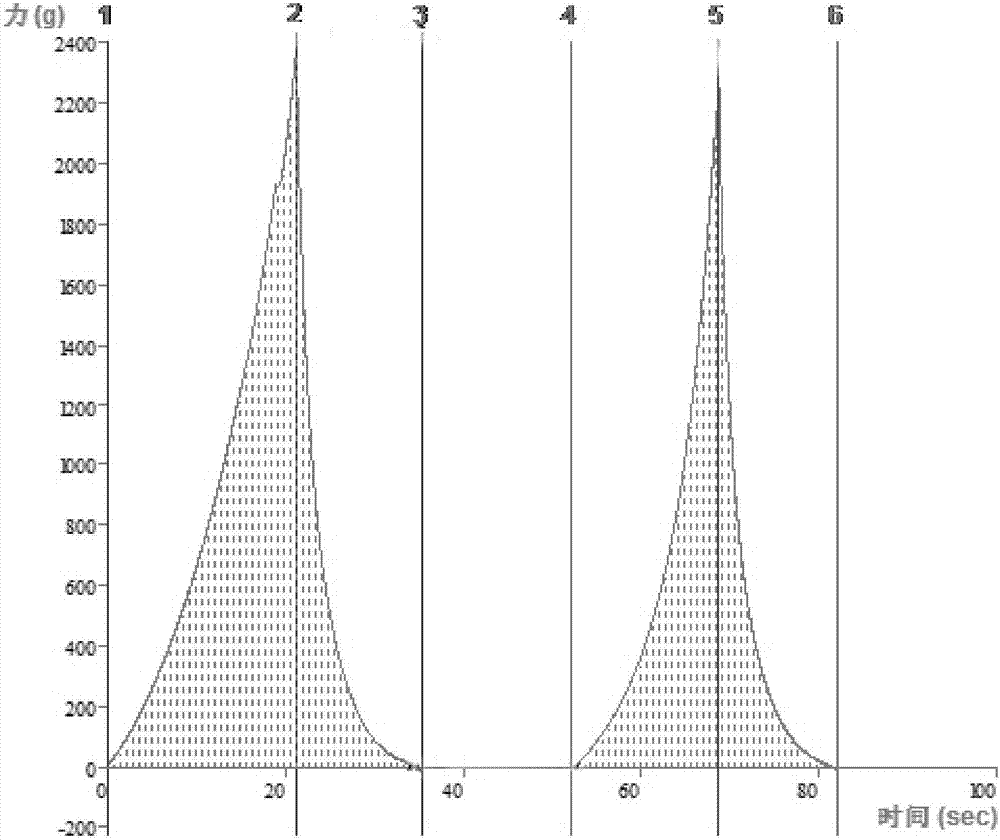

A manufacturing method of yolk particles used for aquatic feed, the yolk particles, and the aquatic feed are provided. The method includes freezing fresh egg yolks to a solid state, cooking the frozen yolks in water until the yolks are cooked and a solid state is formed, and processing the cooked yolks into particles. The cooked yolk particles prepared by the method, when being compared with unprocessed cooked yolk particles, are at least advantageous in that 1) hardness and elasticity are better, and the cooked yolk particles are not liable to be broken by water flow shock or movements of aquatic organisms such as fish and shrimp, so that stability in water is better; 2) the cooked yolk particles are suitable for digestion and absorption by aquatic organisms such as fish and shrimp; and 3) food ingestion of fish and shrimp is facilitated.

Description

technical field [0001] The invention relates to the technical field of aquatic feed, in particular to a method for manufacturing egg yolk granules used as aquatic feed, egg yolk granules used as aquatic feed, and aquatic feed. Background technique [0002] my country is a big country of aquatic products in the world. In 2016 alone, the output of aquatic products in my country was 69 million tons. Because in my country, the annual output of eggs is high, and the nutritional value of egg yolks is high, my country has a tradition of using boiled egg yolks as aquatic feed, especially in occasions such as cultivating fish fry. However, boiled egg yolks are easy to lose or collapse when soaked in water, which is not convenient for aquatic organisms such as fish and shrimp to eat. This not only causes sediment waste, but also makes the water quality eutrophic, which in turn causes bacterial growth, resulting in muddy and bad water, which is not conducive to fish Aquatic organisms ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23K50/80A23K10/20A23K10/30A23K10/26A23K20/147A23K40/10

CPCY02A40/818A23K50/80A23K10/20A23K10/26A23K10/30A23K20/147A23K40/10

Inventor 吴灵英熊江林王宗俊熊力力

Owner WUHAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com