Ultra-trace liquid sample feeding device

A technology of trace liquid and sample injector, which is applied in the field of biochemical experiments, can solve problems such as unsatisfactory, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

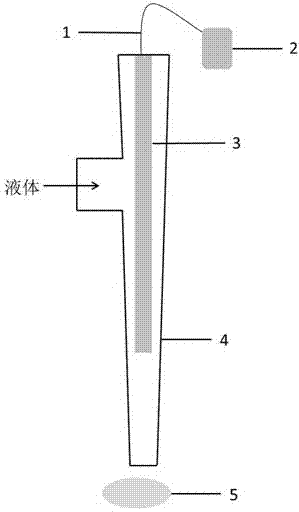

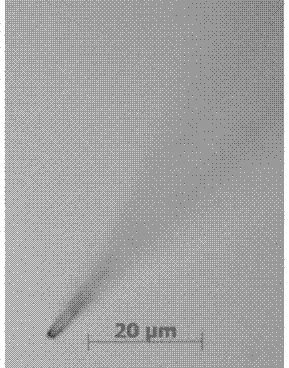

[0022] Step 1, preparing a capillary, the inner diameter of the capillary is 1 micron, and the outer diameter is 3 microns; the capillary is a glass tube; the side wall of the capillary is opened with a liquid inlet at two-thirds of the height;

[0023] Step 2. Place the copper wire in the capillary, and the copper wire is located at about two-thirds of the middle and back end (the upper part in the figure) of the capillary;

[0024] Step 3. Pump the trace liquid from the left inlet of the capillary into the capillary by the trace liquid pump;

[0025] Step 4. Adjust the temperature of the heating source, and transfer the heat to the copper wire through the heat conduction wire;

[0026] Step 5. Add the liquid drop by drop to the required container through the thermal expansion of the copper wire, and the size of each drop is about 0.1 picoliter.

Embodiment 2

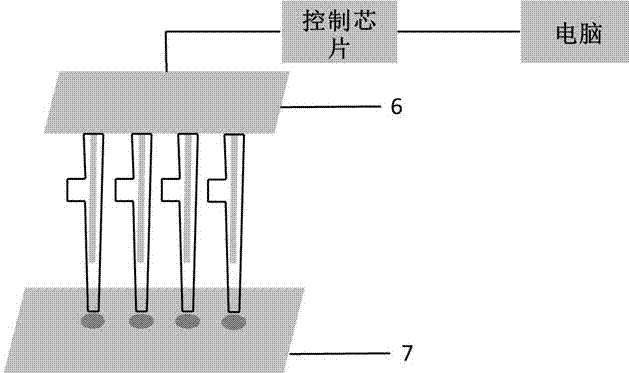

[0028] Step 1, preparing an array sampler composed of a plurality of capillaries, the inner diameter of the capillary is controlled within 1-10 microns, and the outer diameter is controlled within 2-20 microns; each capillary is made of a glass tube; One liquid inlet is opened at the two heights;

[0029] Step 2. Place a copper wire in each capillary, and the copper wire is located at about two-thirds of the middle and back end (the upper part in the figure) of the capillary;

[0030] Step 3. Pump the trace liquid into the capillary from the left inlet of the capillary by the trace liquid pump,

[0031] Step 4. Adjust the temperature of the heating array, and transfer the heat to the copper wire through the heat conduction wire;

[0032] Step 5. Control the XYZ three-axis movement of the sample stage through the computer, and move the sample stage to the desired position;

[0033] Step 6. Add the liquid drop by drop to the required container through the thermal expansion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com