Intelligent steel bar straightening and cutting mechanism

A cutting mechanism and straightening technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inaccurate cutting length of steel bars, time-consuming operation, complex structure, etc., and achieve a simple and effective counting method, simple structure, and reduced The effect of the probability of security incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

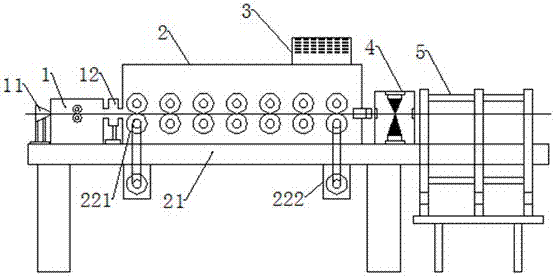

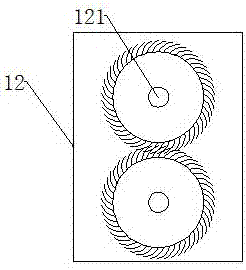

[0034] The present invention is realized through the following technical solutions, as Figure 1-Figure 4 As shown, a kind of intelligent steel bar straightening and cutting mechanism 4 is used for straightening and cutting of steel bars, including an operation platform 21 equipped with feeding mechanism 1, straightening mechanism 2 and cutting mechanism 4, and also includes feeding mechanism 1, The PLC controller 3 connected to the straightening mechanism 2 and the cutting mechanism 4, the straightening mechanism 2 includes a housing provided with a second feed port and a second discharge port, a drive roller 221 installed inside the housing, an installation The driven roller 222 used in cooperation with the driving roller 221 inside the housing and the motor 223 used to drive the driving roller 221 to rotate, the PLC controller 3 is connected to the motor 223 .

[0035] Working principle: as image 3As shown, first set the steel bar in the PLC controller 3 through the strai...

Embodiment 2

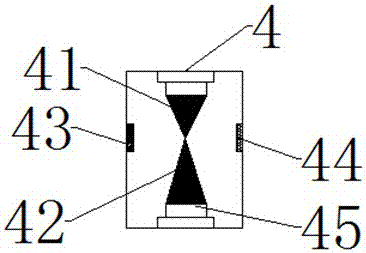

[0039] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 , figure 2 , Figure 4 As shown, the cutting mechanism 4 includes a cutting box, an upper cutting blade 41 and a lower cutting blade 42 installed in the cutting box, and an infrared receiving device 44 installed on the side wall of the cutting box casing, and is arranged opposite to the infrared receiving device 44. And the infrared emission device 43 that cooperates to use; The side that described upper cutting blade 41 is near the inner wall of cutting box top is provided with the elevating device 45 that drives upper cutting blade 41 to reciprocate up and down, and described lower cutting blade 42 is close to cutting box One side of the inner wall of the bottom is provided with a lifting device 45 that drives the lower cutting blade 42 to reciprocate up and down. The lifting device 45, the infrared emitting device 43 and the infrared receiving device 44 are connected to the...

Embodiment 3

[0046] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 , Figure 4 As shown, the driving roller 221 is coaxially installed with a rotating shaft, and the rotating shaft is connected to the output shaft of the motor 223 through a belt.

[0047] Through the belt drive, the transmission method is simple.

[0048] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com