Temperature isostatic press

A warm isostatic press and high-pressure technology, applied in the field of static presses, can solve the problems of warm isostatic presses such as bulkiness, complex structure, and high noise, and achieve the effects of simple structure, reasonable structure design, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

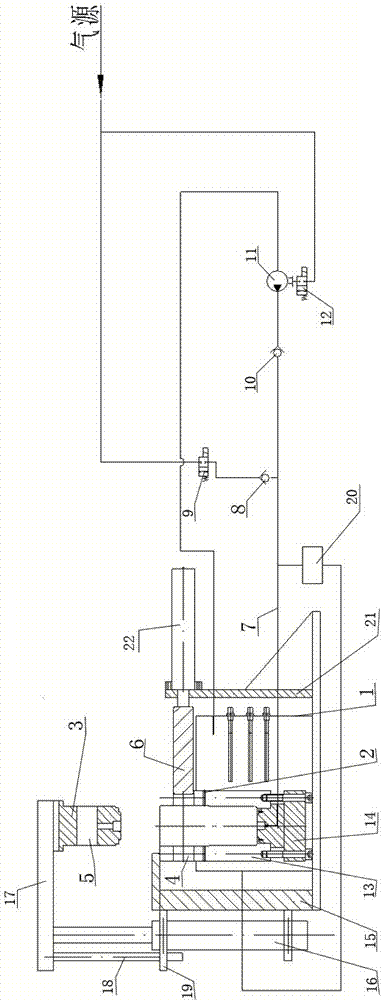

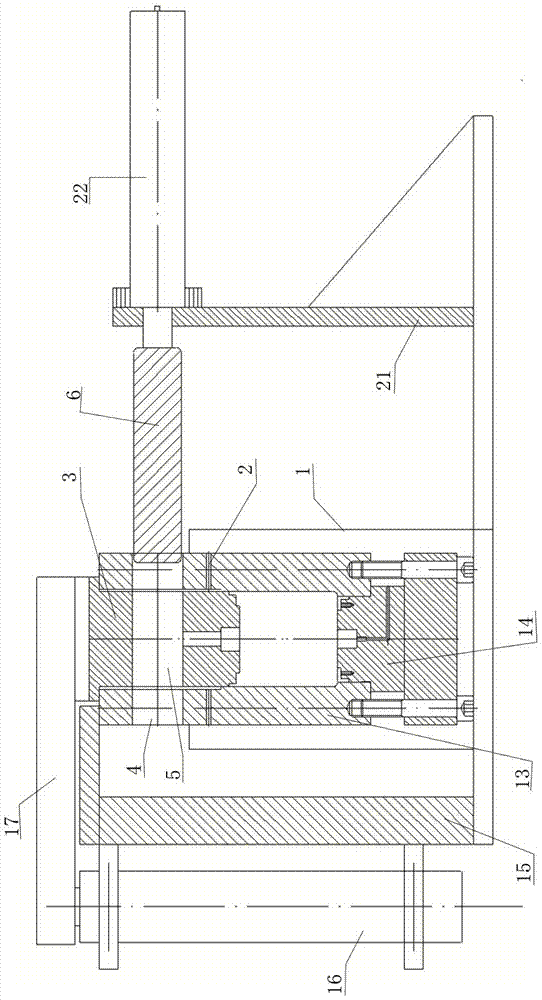

[0010] The warm isostatic press includes a high-pressure chamber, which is placed in a heating water tank 1 with heating components inside, and a piston hole 2 is opened on the side wall of the high-pressure chamber to allow the water in the heating water tank to enter the high-pressure chamber; The top of the chamber is provided with an upper piston 3 for sealing the opening and closing of the high-pressure chamber mouth. The part of the high-pressure chamber protruding from the heating water tank is provided with a pin hole 4 that passes through the high-pressure chamber vertically. The upper piston 3 is provided with a pin hole 5. When the upper piston 3 closes the mouth of the high-pressure chamber, the driven pin 6 passes through the pin hole 4 on the high-pressure chamber and the pin hole 5 on the upper piston at the same time. At this time, the length of the upper piston ensures that the upper piston also seals and blocks the high-pressure chamber at the same time. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com