Multi-pivot belt automatic deviation-rectifying device

An automatic deviation rectification device and deviation rectification technology, applied in transportation and packaging, conveyor objects, rollers, etc., can solve the problems of high use and maintenance costs, complex structure of hydraulic deviation rectifiers, and low deviation rectification sensitivity, and achieve simplified structure and deviation rectification. The effect of high traction sensitivity and high deviation correction sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

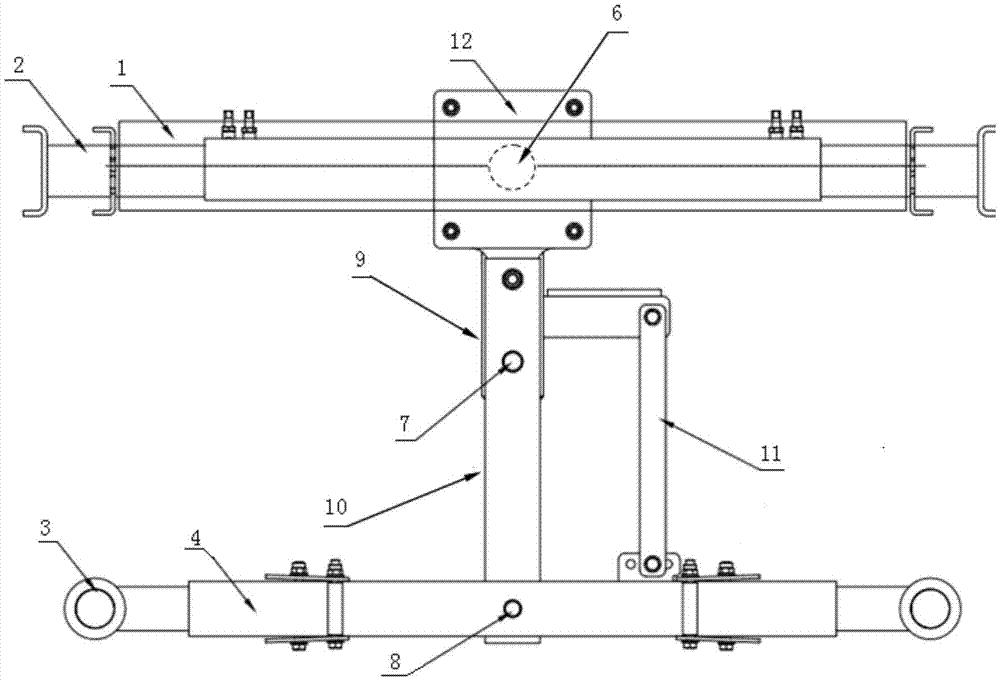

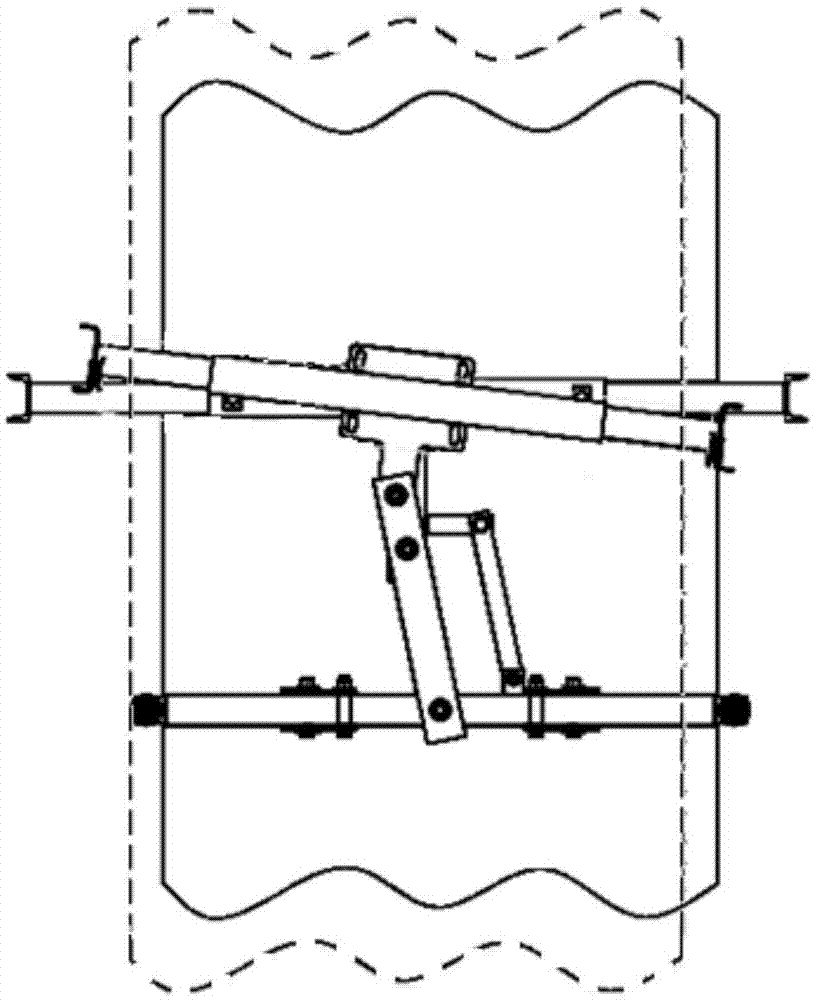

[0016] Embodiment 1: as Figure 1-2 The multi-pivot belt automatic deviation correction device shown includes deviation correction idler 1, deviation correction idler bracket 2, induction idler 3, induction idler adjustment arm 4, installation base 5, main pivot bearing 6, and first auxiliary rotation bearing 7 , the second pair of rotating bearings 8, the primary swing rod 9, the secondary swing rod 10, the linkage swing rod 11, the fixed plate 12, and the deviation correction roller 1 are installed on the deviation correction roller support 2. The induction roller 3 is arranged on the adjustment arm 4 of the induction roller. The deviation correcting idler bracket 2 is arranged horizontally and parallel to the induction idler adjustment arm 4 . One end of the primary swing link 9 is fixedly connected to the symmetrical center position of the deviation correcting roller bracket 2 . One end of the primary swing link 9 is fixedly connected to the symmetrical center position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com