HILS (hardware-in-the-loop simulation) test bed for electromechanical brake booster and testing method

An electro-mechanical braking and test-bed technology, applied in the testing of mechanical parts, the testing of machine/structural parts, instruments, etc., can solve problems such as the inability of electro-mechanical booster test algorithms to improve the subjective evaluation of pedal feel, so as to improve performance. Efficiency and real-time, good repeatability, high simulation effect

Active Publication Date: 2017-09-26

JILIN UNIV

View PDF14 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The electromechanical brake booster hardware-in-the-loop simulation test bench and test method solve the shortcomings that the existing test be

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

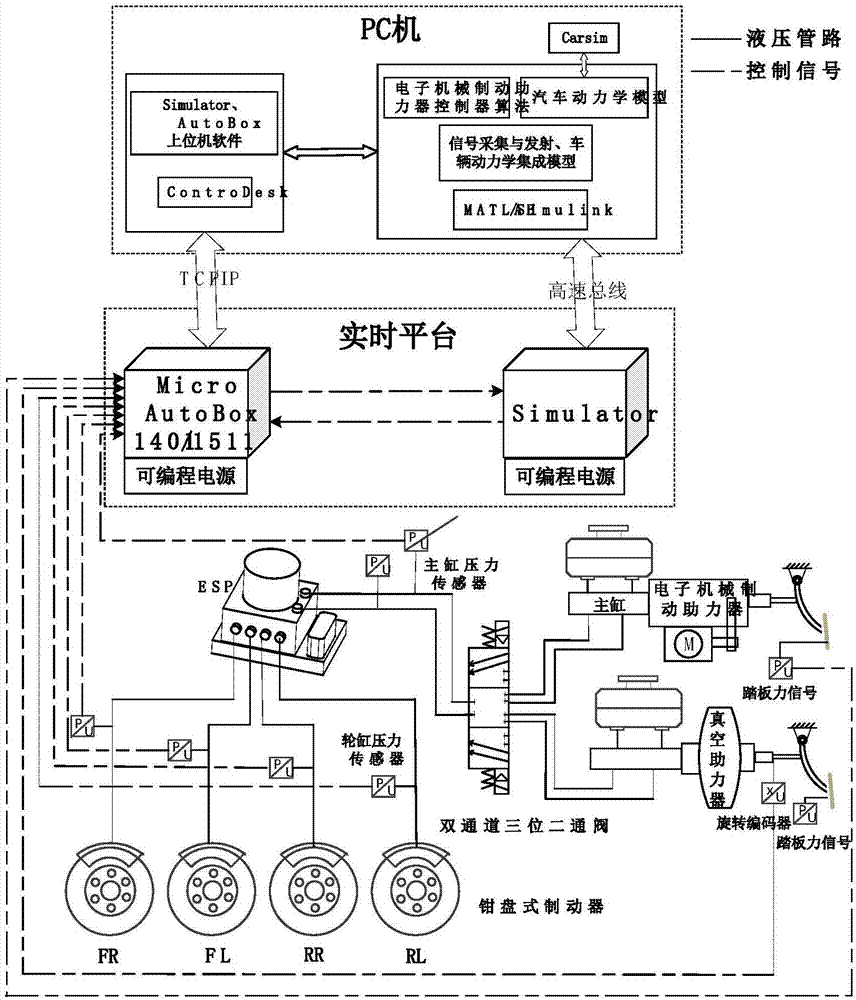

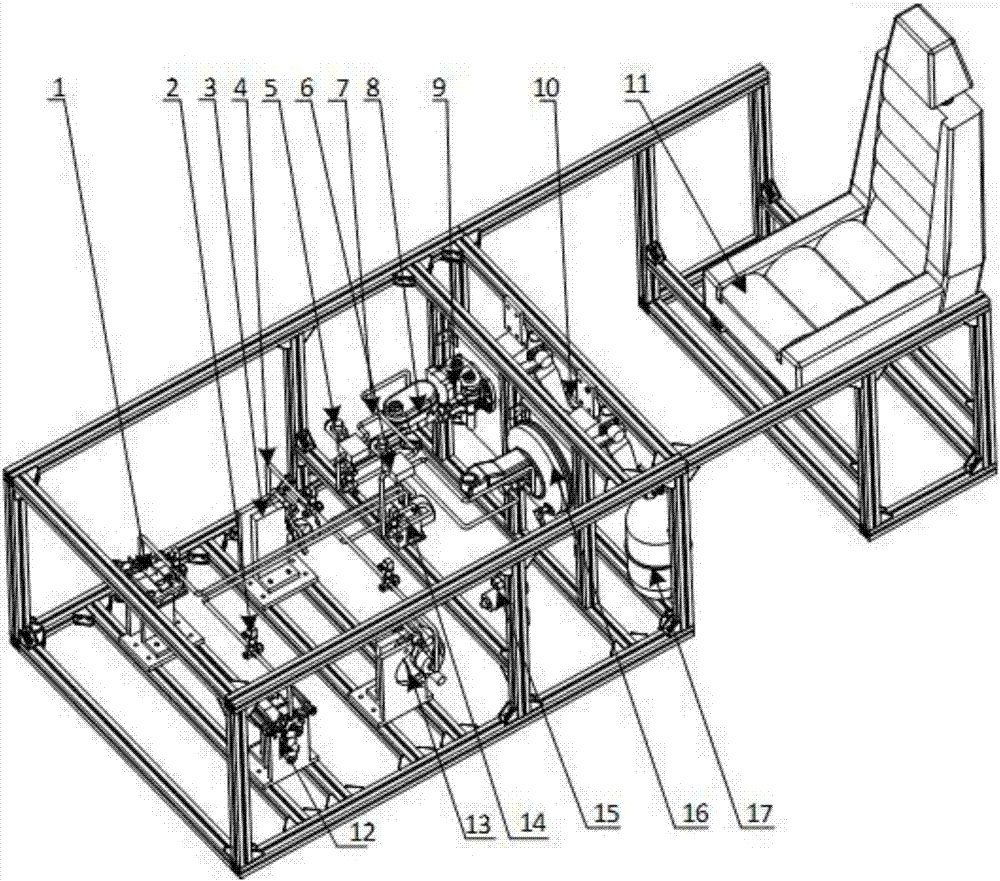

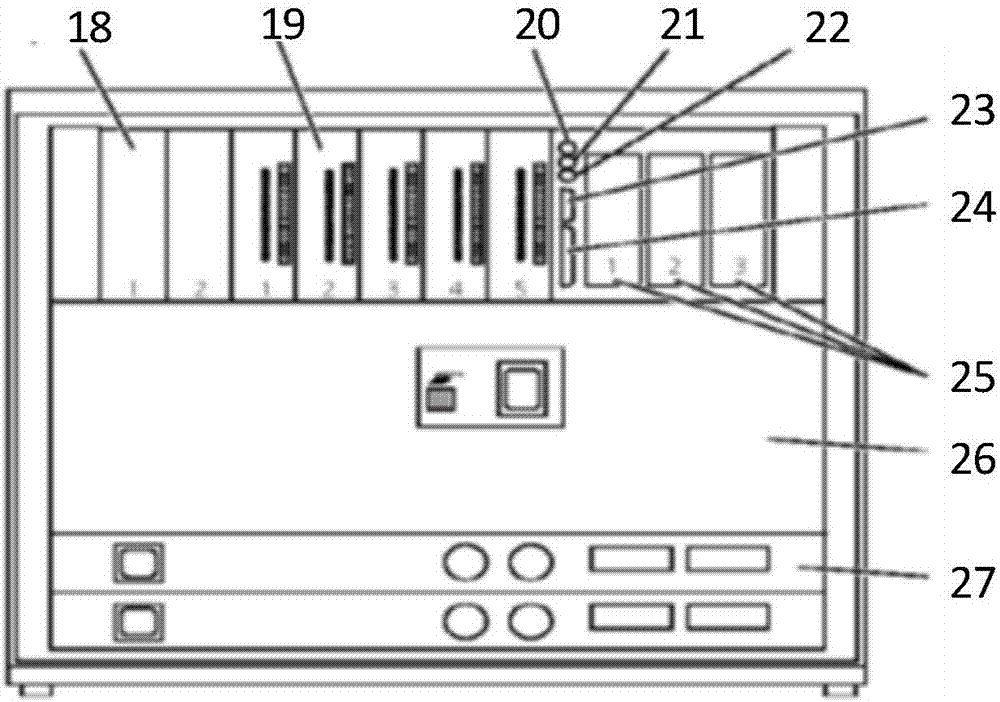

The invention belongs to the field of semi-physical simulation tests, and particularly provides an HILS (hardware-in-the-loop simulation) test bed for an electromechanical brake booster and a testing method. The test bed comprises a PC (personal computer), a real-time simulation platform, a hardware platform and a signal collection and emission platform, wherein the PC is connected with the real-time simulation platform through a high-speed special bus with a cable serving as a medium; the signal collection and emission platform is connected with the PC on the basis of a TCP/IP (transmission control protocol/internet protocol) through a local area network and performs signal communication with the hardware platform through a sensor. The HILS test bed is a real-time simulation platform unit, tests of hardware of the electromechanical brake booster, an automobile dynamics simulation model, an ESP (electronic stability program) of an automobile and actuator equipment in a simulation loop can be realized, and the problem that an existing test stand cannot perform testing, calibration, algorithm improvement and subjective assessment of pedal feeling on the electromechanical brake booster in a concentrated manner is solved.

Description

technical field [0001] The invention belongs to the field of semi-physical simulation tests, in particular to a hardware-in-the-loop simulation test bench and a test method for an electromechanical brake booster. Background technique [0002] The continuous improvement of people's requirements for automobile performance has led to the continuous innovation of auto parts technology, and the automobile braking system is a necessary guarantee for safety, environmental protection, and intelligence. Traditional vacuum booster devices can no longer meet these needs. What emerged at the historic moment was a braking system based on an electromechanical booster. From the point of view of structural characteristics, it abandons the traditional vacuum booster, and replaces the vacuum source with motor power as a booster source to meet the braking requirements of electric vehicles. From the perspective of functional characteristics, the braking system with electromechanical booster re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00

CPCG01M13/00Y02P90/02

Inventor 吴坚陈朋成马秀丹刘迪

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com