Discharge member, charge eliminating device including the same, and image forming apparatus

A component and image technology, applied in the field of charge removal devices, can solve the problems of photocarrier residue or accumulation, and achieve the effects of increasing discharge points, preventing damage, and high-efficiency discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

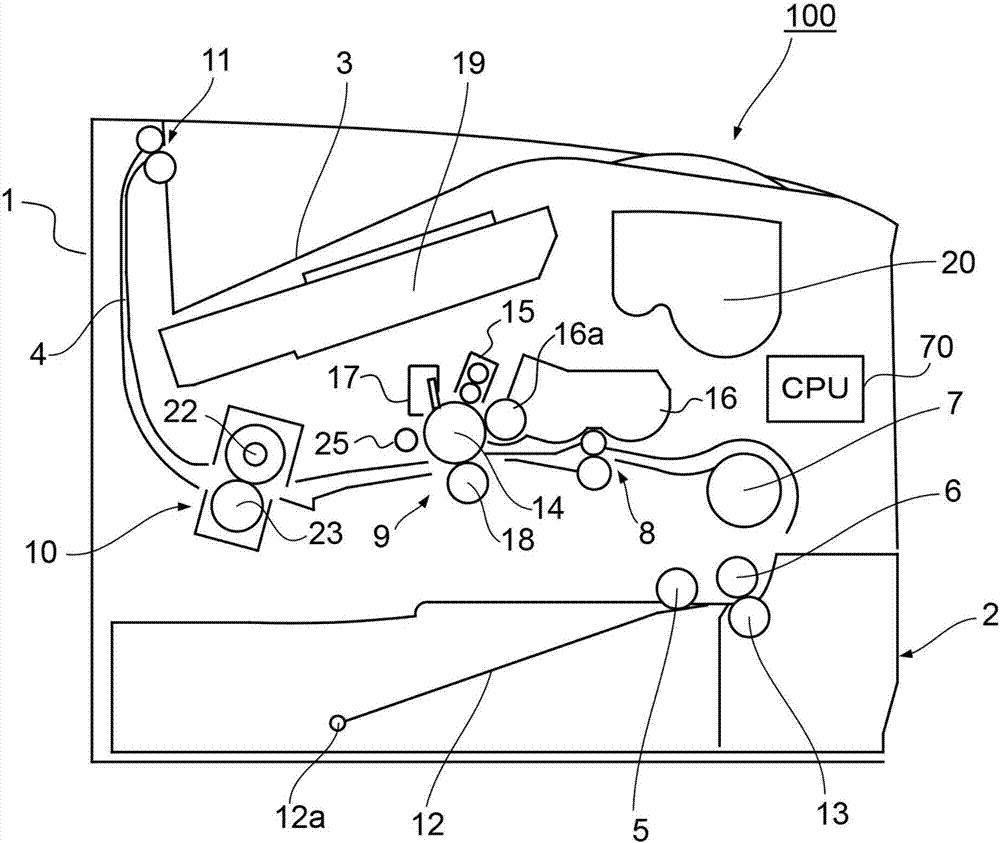

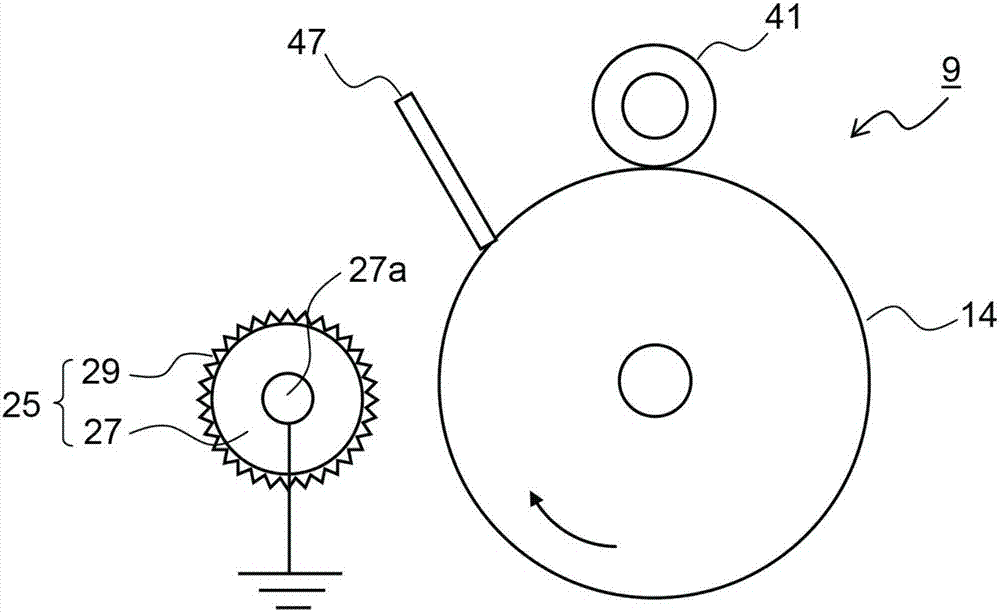

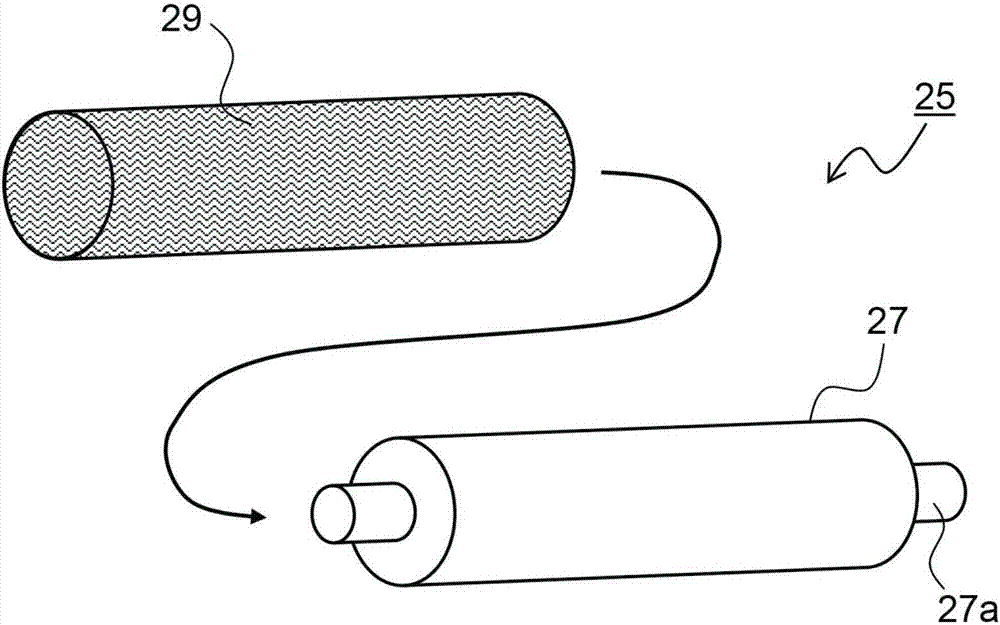

[0094] Use with figure 2 , Figure 5 ~ Figure 7 and Figure 10 In the image forming apparatuses 100 (present inventions 1 to 9) of the first to third embodiments and the fifth embodiment of the image forming unit 9 shown, the decharge performance and durability performance of the decharge roller 25 were evaluated. Regarding the decharge performance, it was checked whether or not a desired post-decharge potential could be obtained after the residual charge of the photosensitive drum 14 was removed by the decharge roller 25 . For durability performance, the presence or absence of streaked images after outputting 50 thousand (50,000) sheets of halftone images with a printing ratio of 25% was confirmed.

[0095] The experimental conditions are as follows: FS-13200 modified machine (manufactured by Kyocera Document Information Systems Co., Ltd.) was used as the image forming apparatus 100, a member in which OPC was laminated on an aluminum tube blank with a diameter of 30 mm was...

Embodiment 2

[0107] use Figure 11 and Figure 12 In the image forming apparatus 100 of the sixth embodiment (the present inventions 10 to 14) in which the magnet member 33 having two magnetic poles with different magnetic forces that become extremely large peaks is arranged inside the photosensitive drum 14, the decharge roller was evaluated. 25 for charge removal performance, image retention and durability. In addition, the image forming apparatus 100 (Comparative Example 5) in which no magnet member is arranged inside the photosensitive drum 14 and the image forming apparatus 100 (Comparative Example 6) in which a magnet member 33 having only one magnetic pole is arranged inside the photosensitive drum 14 are used. to 8), the same evaluation was performed. The test methods, test conditions and evaluation criteria of the charge removal performance and durability performance are the same as in Example 1. With regard to image sticking, the presence or absence of image sticking caused by...

Embodiment 3

[0116] use for Figure 14The eighth embodiment in which the first magnet member 33 a and the second magnet member 33 b are arranged inside the photosensitive drum 14 and the arrangement of the first magnet member 33 a and the second magnet member 33 b is switched according to the state of the image forming apparatus 100 is shown. In the image forming apparatus 100 (present inventions 15 to 20), the decharge performance and durability performance of the decharge roller 25 were evaluated during durable (50,000 sheets) printing and after long-term (8 hours) standing. In addition, the decharge performance and density unevenness of the decharge roller 25 in the half-speed (1 / 2 speed during normal printing) mode, and the decharge performance of the decharge roller 25 during the drum regeneration operation (DR) were also evaluated. and pinhole generation.

[0117] The charge removal performance, the test method, test conditions and evaluation criteria of the durability performance a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com