Vehicle Pneumatic Tires

A technology for pneumatic tires and vehicles, applied to vehicle parts, tire parts, tires, etc., can solve the problems of delayed sealing effect, non-appearance, difficulty, etc., and achieve reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

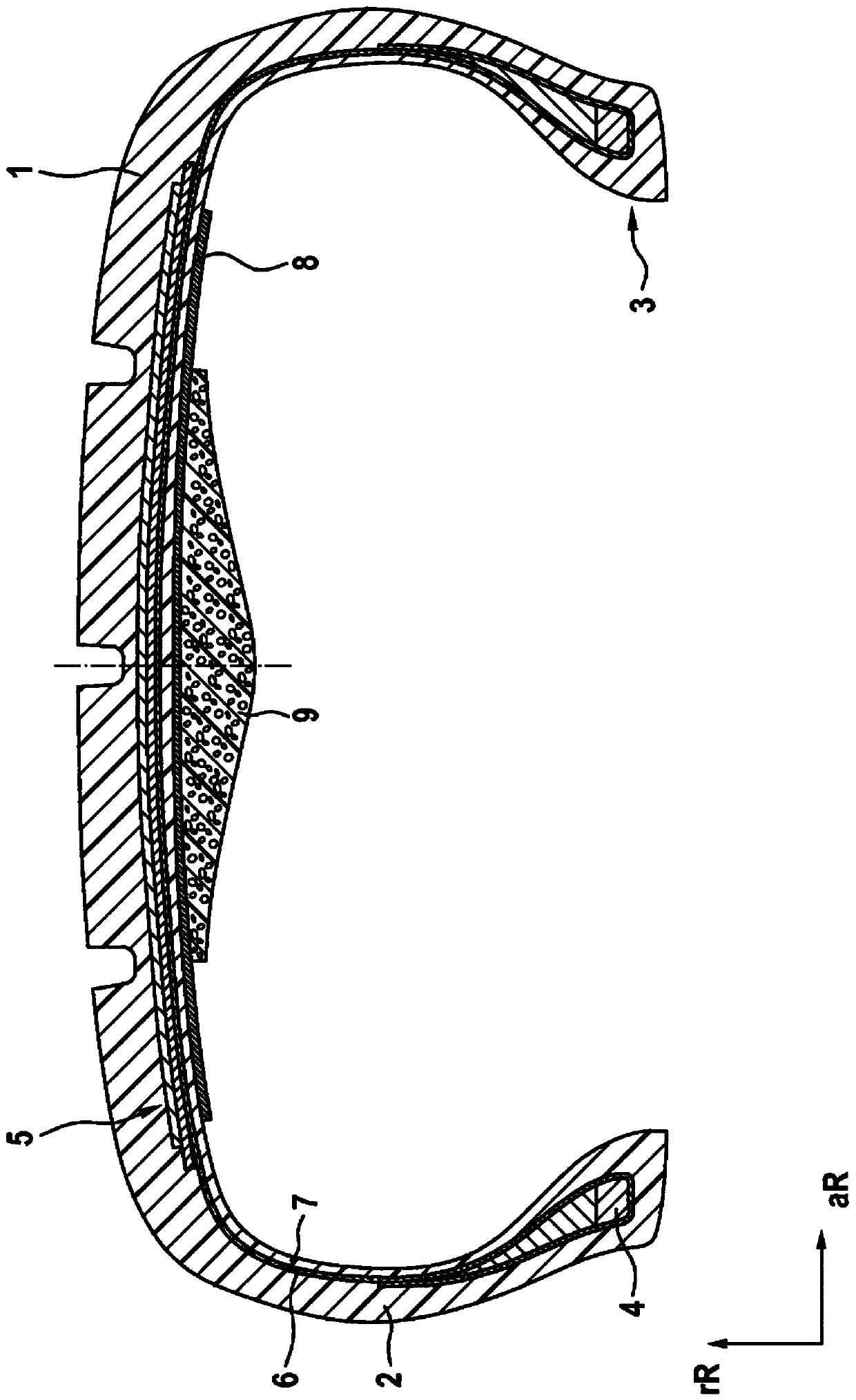

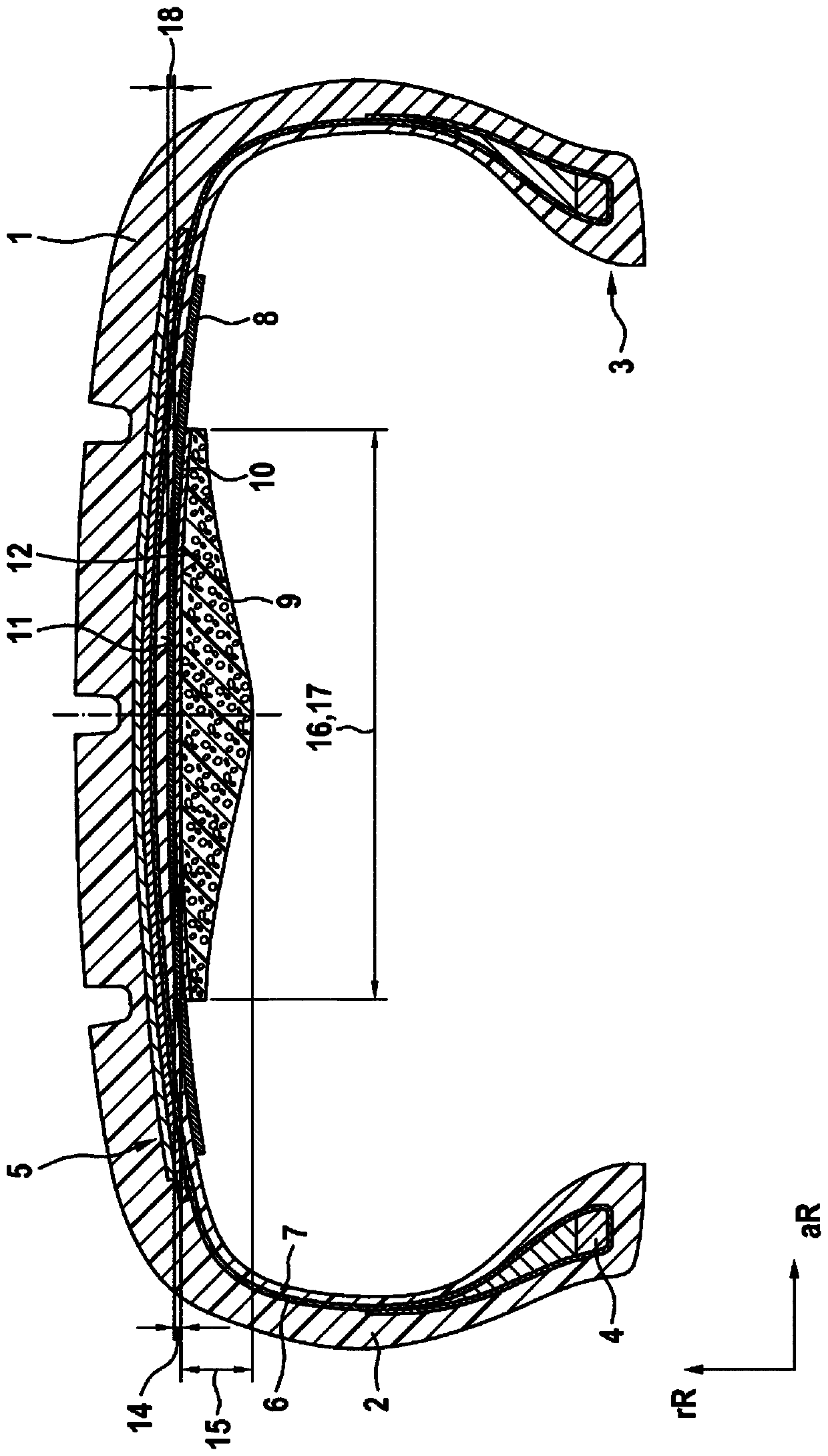

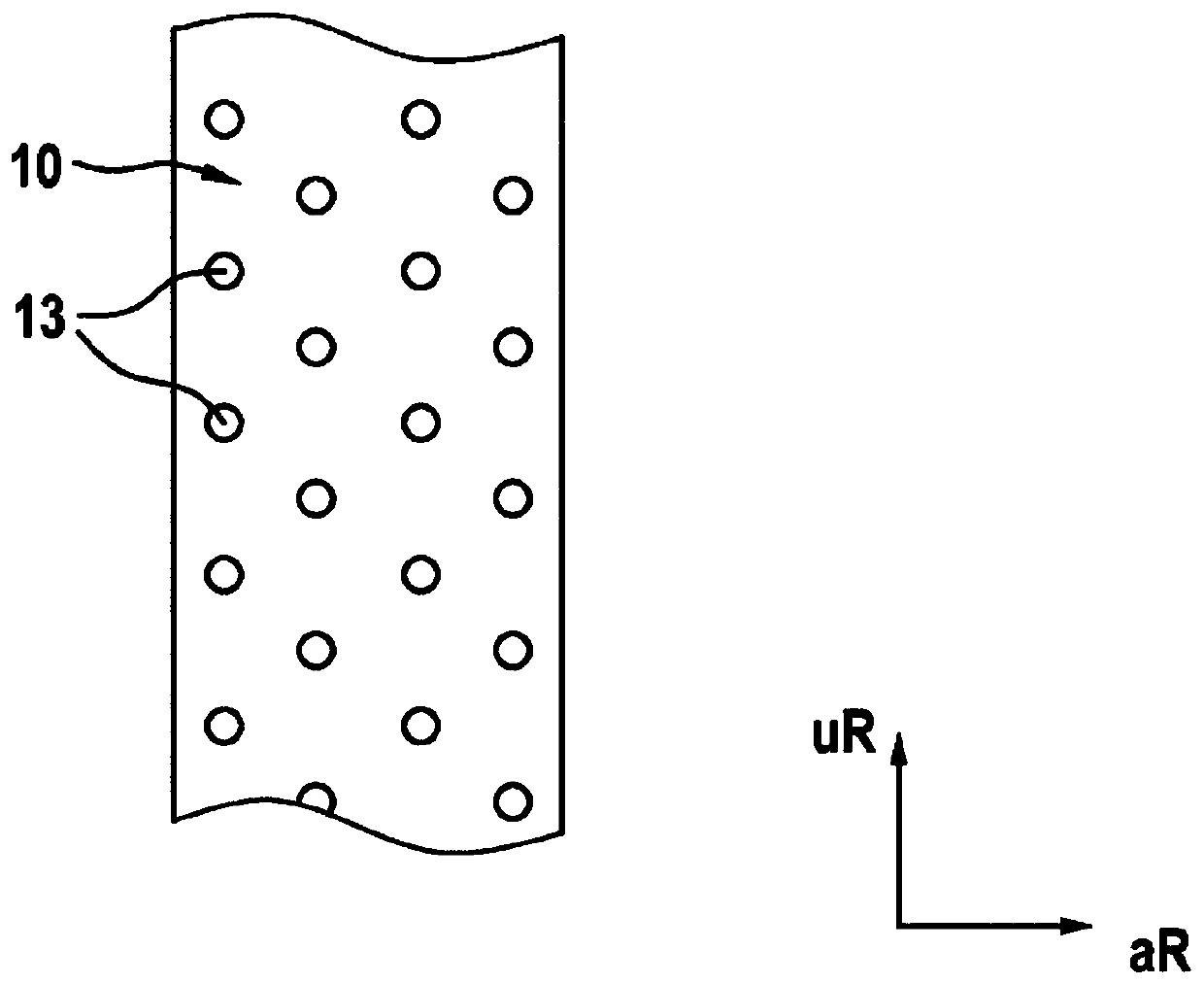

[0040]In Fig. 1 a cross section through a radial passenger car tire is shown, with a profiled tread 1, sidewalls 2, bead regions 3, bead cores 4 and multiple layers of cord belt compound 5 and carcass layer 6. At its inner face, the tire is covered with an inner layer 7 of an airtightly implemented rubber compound. At the inner surface of the inner layer 7 opposite the tread 1 is applied a sealant 8 capable of producing a self-sealing action in the event of a puncture (tire damage). Adhere to the sealant 8 is an inner absorbent body 9 which is pressed against the sealant 8 just after application of the sealant 8 (provided there is still sufficient adhesiveness), as described below. The inner absorber 9 is frequency-adapted to the tire cavity in terms of its sound-absorbing properties. In this case, the inner absorbent body 9 has, for example, an approximately elongated triangular cross-section symmetrical to the tire equator. The foam material of the inner absorber 9 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com