Thermosensitive adhesive material

A kind of adhesive material, heat-sensitive technology, applied in the direction of adhesive type, ester copolymer adhesive, nitrile copolymer adhesive, etc., can solve the problems such as inability to obtain adhesiveness, thermal responsiveness decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

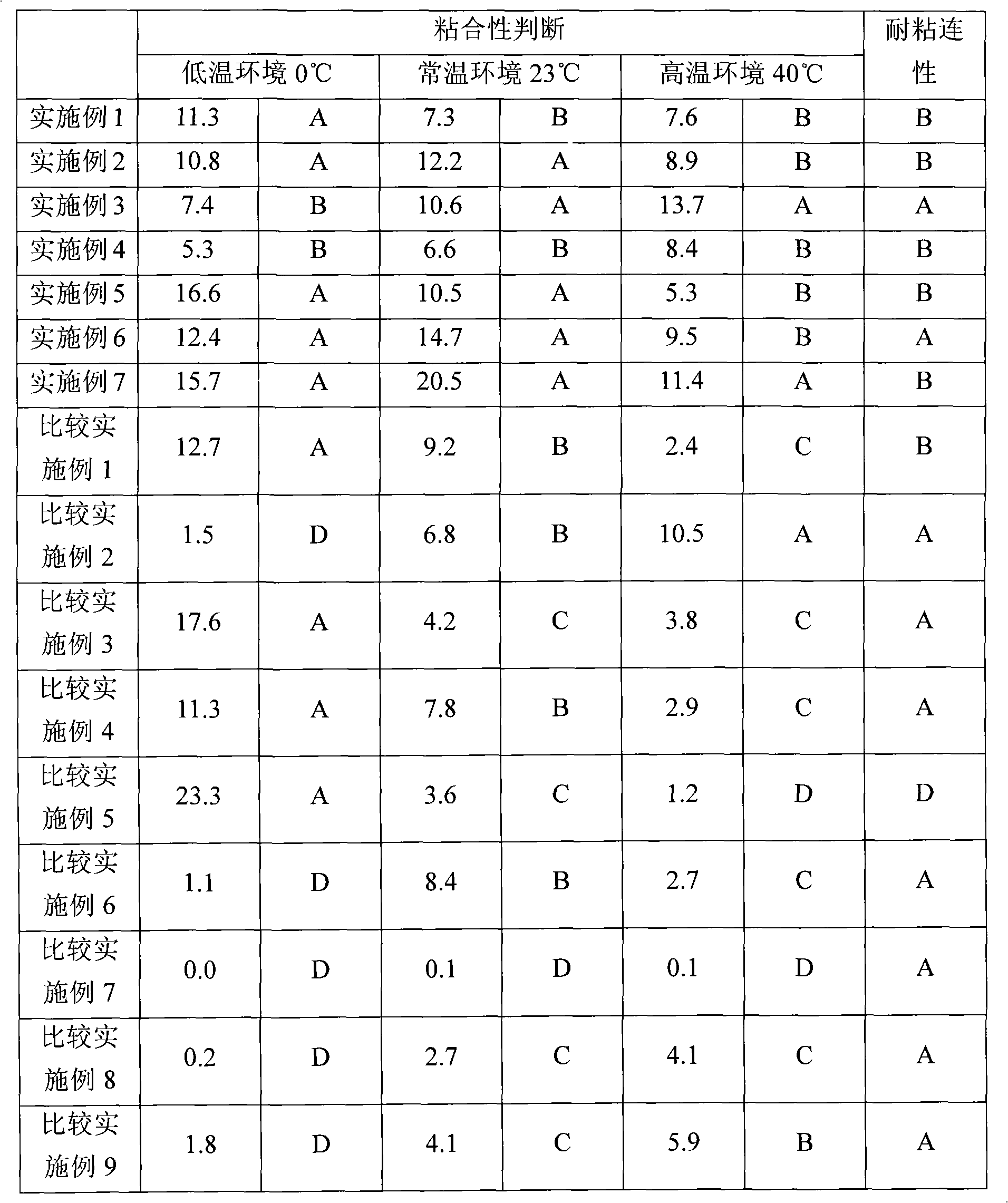

Examples

Embodiment 1

[0209] [0135] On single-side coated paper (OK ADNIS ROUGH, produced by Oji paper Co., Ltd.) - this single-side coated paper acts as a carrier and has 80 g / m 2 Paper basis weight of - on the surface of the side of which no coating is provided, a heat-sensitive adhesive layer coating solution [R solution] comprising a resin having a monomeric structure A is applied and dried so that its dry adhesion amount is 20g / m 2 , thus forming a heat-sensitive adhesive layer, and thus producing a heat-sensitive adhesive material.

Embodiment 2

[0211] [0136] A heat-sensitive adhesive layer was formed in a similar manner to Example 1, except that the resin having the monomer structure A was changed to the resin having the monomer structure B; and thus a heat-sensitive adhesive material was produced.

Embodiment 3

[0213] [0137] A heat-sensitive adhesive layer was formed in a similar manner to Example 1, except that the resin having the monomer structure A was changed to the resin having the monomer structure C; and thus a heat-sensitive adhesive material was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com