Multilayer film, method for producing same, and aqueous dispersion used for production of same

A water-based dispersion, laminated film technology, applied in other household appliances, chemical instruments and methods, coatings, etc., can solve the problems of easy adhesion, poor solvent resistance, poor resistance to contents, etc., and achieve excellent resistance to contents, The effect of excellent solvent resistance and sufficient lamination strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

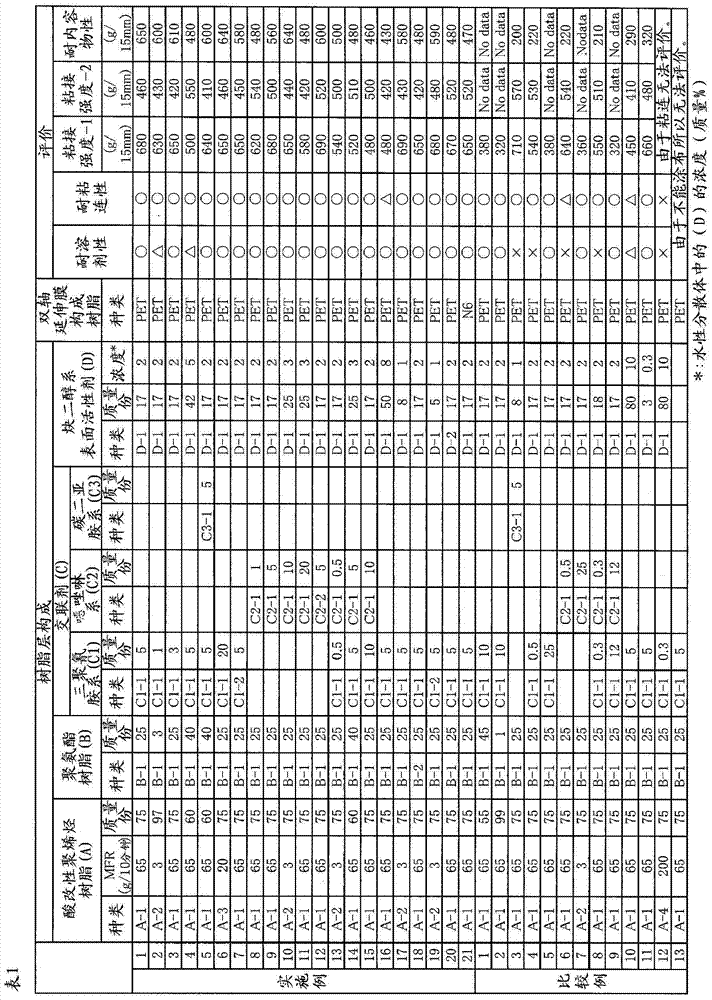

Examples

Embodiment

[0094] Next, the present invention will be specifically described based on examples. The raw materials used and the preparation method of the aqueous dispersion of the acid-modified polyolefin resin are as follows.

[0095] (A) Acid-modified polyolefin resin:

[0096] (A-1) BONDINE HX-8290 (ethylene / ethyl acrylate / maleic anhydride=80 / 18 / 2 (mass %), MFR: 65 g / 10 min, melting point: 81° C., manufactured by ARKEMA Corporation

[0097] (A-2) BONDINE TX-8030 manufactured by Arkema Corporation (ethylene / ethyl acrylate / maleic anhydride=85 / 12 / 3 (mass %), MFR: 3 g / 10 minutes, melting point: 95° C.)

[0098] (A-3) BONDINE HX-8140 manufactured by Arkema Corporation (ethylene / ethyl acrylate / maleic anhydride=78 / 19 / 3 (mass%), MFR: 20 g / 10 minutes, melting point: 80° C.)

[0099] (A-4) BONDINE HX-8210 manufactured by Arkema Corporation (ethylene / ethyl acrylate / maleic anhydride=90 / 7 / 3 (mass %), MFR: 200 g / 10 minutes, melting point: 100° C.)

[0100] (B) Polyurethane resin:

[0101] (B-1) ...

reference example 1

[0116] (Preparation of acid-modified polyolefin aqueous dispersion (E-1))

[0117] 60.0 g of acid-modified polyolefin resin (A-1) and 90.0 g of isopropanol (manufactured by Wako Pure Chemical Industries, Ltd., below It may be abbreviated as IPA), 3.0 g of N,N-dimethylethanolamine (manufactured by Wako Pure Chemical Industries, Ltd., hereinafter may be abbreviated as DMEA) and 147.0 g of distilled water were put into a glass container. Then, the rotation speed of the stirring blade was set to 300 rpm, and the temperature in the system was kept at 140 to 145° C., followed by stirring for 30 minutes. Thereafter, it was placed on a water bath, and cooled to room temperature (about 25° C.) while stirring while maintaining a rotational speed of 300 rpm, to prepare an acid-modified polyolefin resin aqueous dispersion. Further, the acid-modified polyolefin resin aqueous dispersion and 180 g of distilled water were put into a double-necked round-bottomed flask, a mechanical stirrer an...

reference example 2

[0119] (Preparation of acid-modified polyolefin aqueous dispersion (E-2))

[0120] Except using acid-modified polyolefin resin (A-2) instead of acid-modified polyolefin resin (A-1), carry out the same operation as Reference Example 1 to obtain acid-modified polyolefin resin (A-2 ) aqueous dispersion (E-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com