Composition for electricity storage devices, slurry for electricity storage devices, electrode for electricity storage devices, separator for electricity storage devices, and electricity storage device

A technology of electric storage device and composition, which is applied to non-aqueous electrolyte battery electrodes, battery electrodes, battery pack components and other directions, can solve the problems of deterioration of charging and discharging characteristics of electric storage devices, peeling of active material layers, etc., and achieves the charging and discharging rate Good characteristics and the effect of preventing position shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

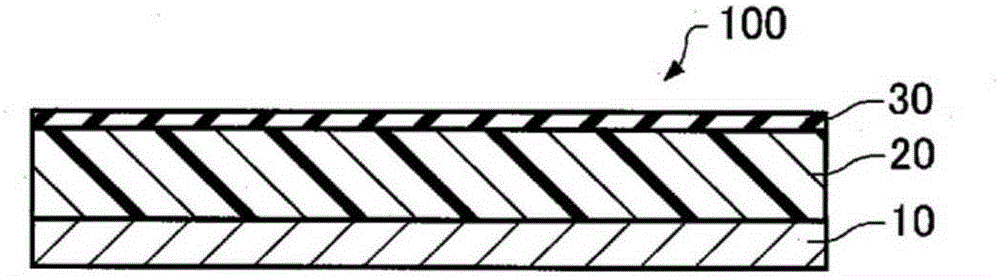

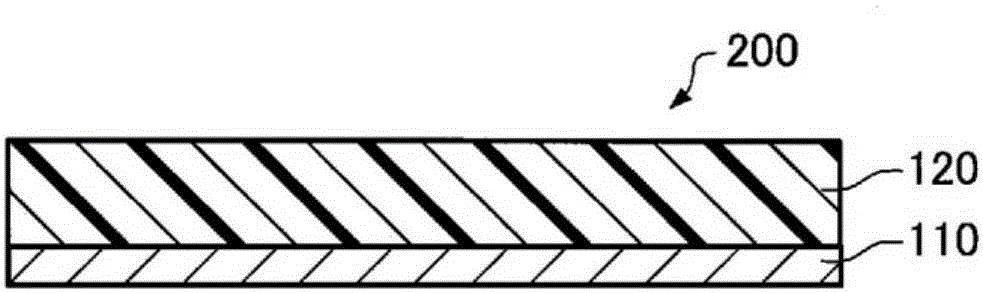

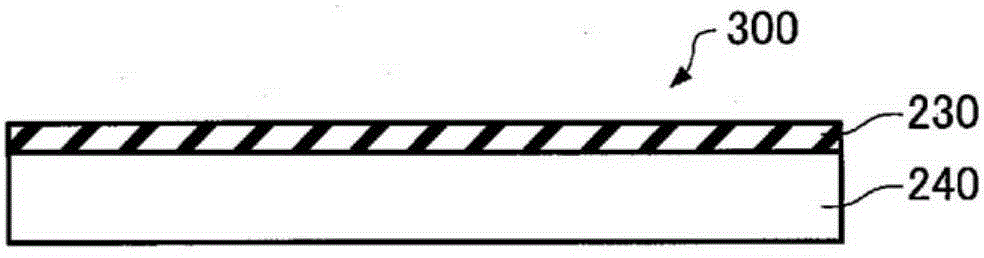

Image

Examples

Embodiment 2~7

[0234] 6.2. Examples 2-7, Comparative Examples 1-3

[0235] In the "6.1.1. Preparation of binder" of the above-mentioned Example 1, except that the composition of the monomer and the amount of emulsifier were changed appropriately, it was carried out in the same manner as in Example 1, and a binder containing the composition shown in Table 1 was prepared. For the aqueous dispersion of the binder, water was removed under reduced pressure or water was added according to the solid content concentration of the aqueous dispersion, thereby obtaining an aqueous dispersion with a solid content concentration of 40%.

[0236] Next, in the "6.1.2. Preparation of the composition for electrical storage devices" of the above-mentioned Example 1, except that the anti-blocking agent was changed to the type and addition amount described in Table 1, it was the same as that of the above-mentioned Example 1. The compositions S2-S7 and S11-S13 for electrical storage devices were prepared in this m...

Embodiment 8

[0239] 150 parts by mass of water and 0.2 parts by mass of sodium dodecylbenzenesulfonate were put into a separable flask with a capacity of 7 liters, and the inside of the separable flask was sufficiently replaced with nitrogen. On the other hand, 60 parts by mass of water, 0.8 parts by mass of ether sulfate-type emulsifier (trade name "AdekariaSoap SR1025", manufactured by ADEKA Corporation) as an emulsifier in terms of solid content, and a single 20 parts by mass of 2,2,2-trifluoroethyl methacrylate (TFEMA), 10 parts by mass of acrylonitrile (AN), 25 parts by mass of methyl methacrylate (MMA), 2-ethylhexyl acrylate (EHA) 40 mass parts and 5 mass parts of acrylic acid (AA) were fully stirred, and the monomer emulsion containing the mixture of the said monomer was prepared. Thereafter, heating of the inside of the separable flask was started, and when the temperature inside the separable flask reached 60° C., 0.5 parts by mass of ammonium persulfate as a polymerization initia...

Embodiment 14

[0284] 6.7.1. Preparation of slurry for protective film formation

[0285] 20 parts by mass of titanium oxide (product name "KR380", manufactured by Titanium Industry Co., Ltd., rutile type, average particle diameter: 0.38 μm) as inorganic particles was mixed with 100 parts by mass of water, and the amount was 5 parts by mass in terms of solid content relative to the inorganic particles. Composition S1 for an electrical storage device obtained in "6.1.2. Preparation of a composition for an electrical storage device" of Example 1 above and 1 part by mass of a thickener (manufactured by DAICEL Co., Ltd., trade name "CMC1120") , using T.K. FILMICS (R) 56-50 type (manufactured by PRIMIX Co., Ltd.) to perform a mixing and dispersing treatment to prepare a slurry for forming a protective film in which titanium oxide was dispersed.

[0286] 6.7.2. Preparation of positive electrode

[0287] As the positive electrode, the slurry for forming the protective film obtained above was coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com