Label for battery casing

A battery shell and label technology, which is applied in the direction of battery box/outer, battery pack parts, battery box/cover materials, etc., can solve the problems of deterioration, strength reduction, difficult labeling cost, etc., and achieve excellent adhesion resistance and low cost The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

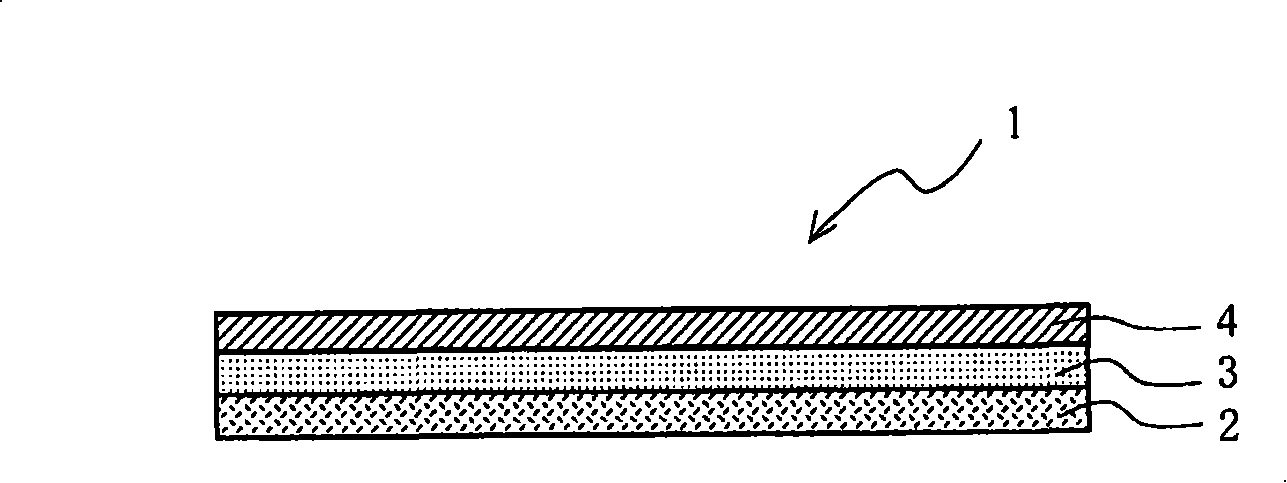

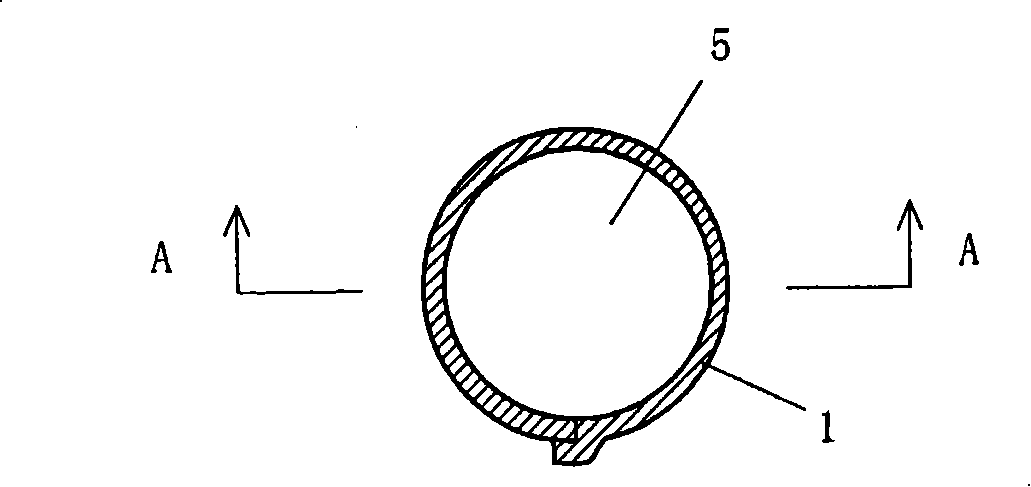

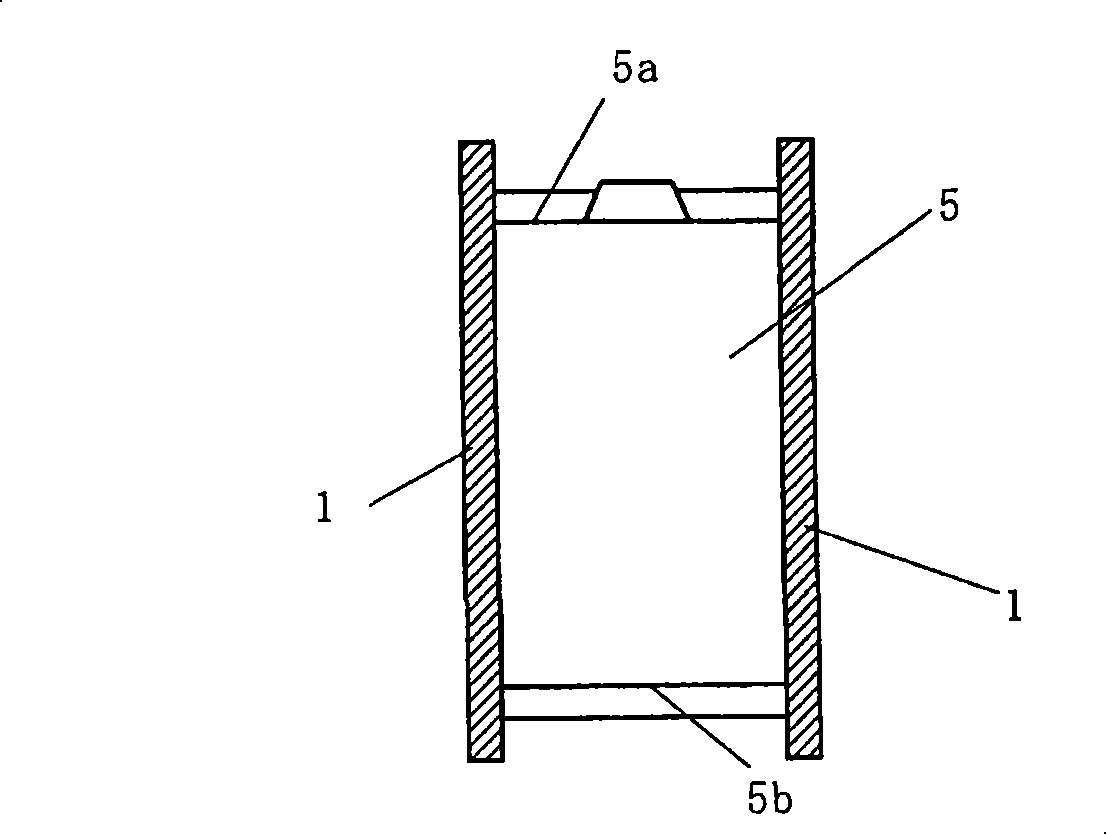

[0059]As the heat-shrinkable film, a heat-shrinkable polyester film (thickness: 50 μm; temperature for starting heat shrinkage: 90° C.) was used. The thermal shrinkage rate in the longitudinal direction (MD direction) of this heat-shrinkable film is 17% under the condition of immersing in a glycerin bath at 110°C for 5 seconds, and 35% under the condition of immersing in a glycerin bath at 140°C for 5 seconds. %, 1.4% under the condition of immersing in a 90°C glycerin bath for 5 seconds. In addition, the heat shrinkage rate in the transverse direction (TD direction) was 2% under the conditions of immersion in a glycerin bath at 110° C. for 5 seconds. After forming a printing layer (thickness 2 μm) by gravure printing various display patterns on one side of the above-mentioned heat-shrinkable film, 88% by weight of ethylene-vinyl acetate copolymer (EVA; Content 72% by weight, melting point 62 ℃, MFR400g / 10 minutes) and 12% by weight of tackifier (terpene resin (trade name "YS...

Embodiment 2

[0061] Except using the EVA (melting point 63 ℃, MFR280g / 10 minutes) 80% by weight of EVA (melting point 63 ℃, MFR280g / 10 minutes) by ethylene content 72% by weight and the same tackifier 20% by weight of embodiment 1 The emulsion type heat-sensitive adhesive (activated temperature about 65° C.) except that the emulsion type heat-sensitive adhesive was used, the same operation as in Example 1 was carried out to produce a label.

Embodiment 3

[0063] In addition to using an emulsion type heat-sensitive adhesive (activation temperature of about 65° C.) prepared from the same EVA80% by weight and tackifier 20% by weight as the emulsion type heat-sensitive adhesive in Example 1, and The same operation as in Example 1 is used to make a label.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com