Adhesive based on non-polar polyolefin resin

A non-polar polyolefin, polyolefin resin technology, applied in the directions of graft polymer adhesives, hydrocarbon copolymer adhesives, adhesive types, etc., can solve the problem of reduced service life and stable adhesives. Poor performance, peeling force can not reach 10N/mm and other problems, to achieve the effect of excellent service life and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

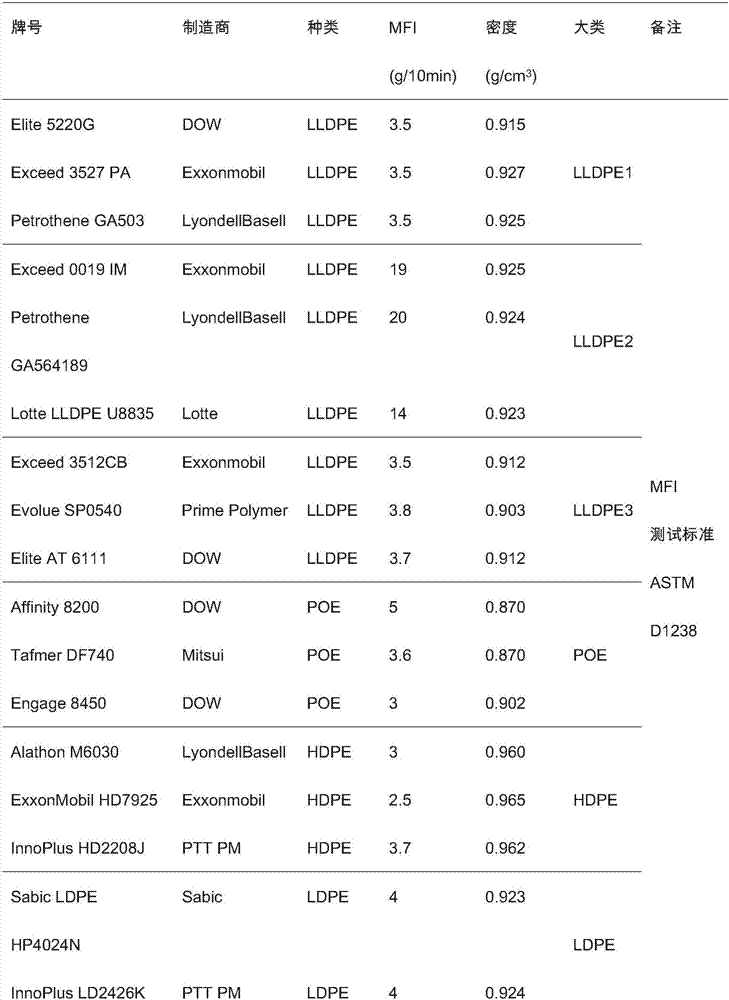

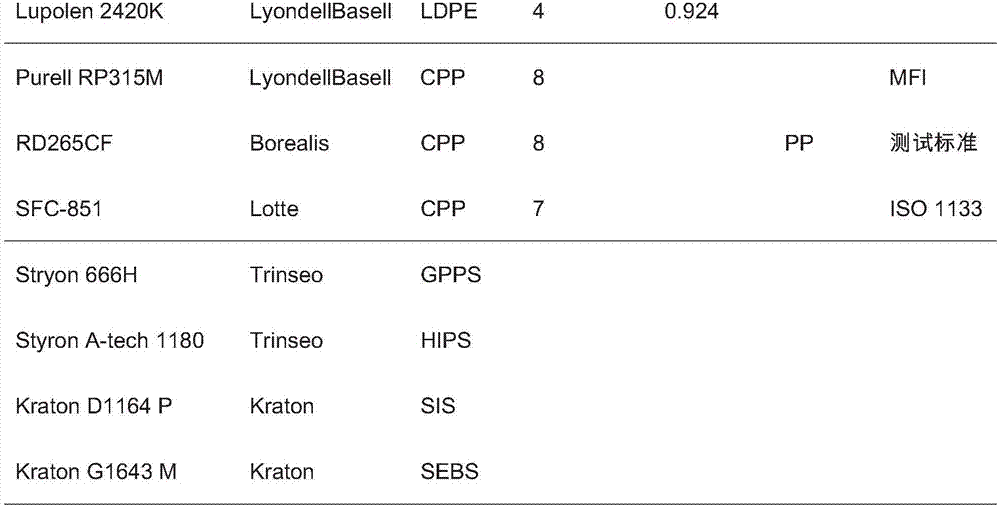

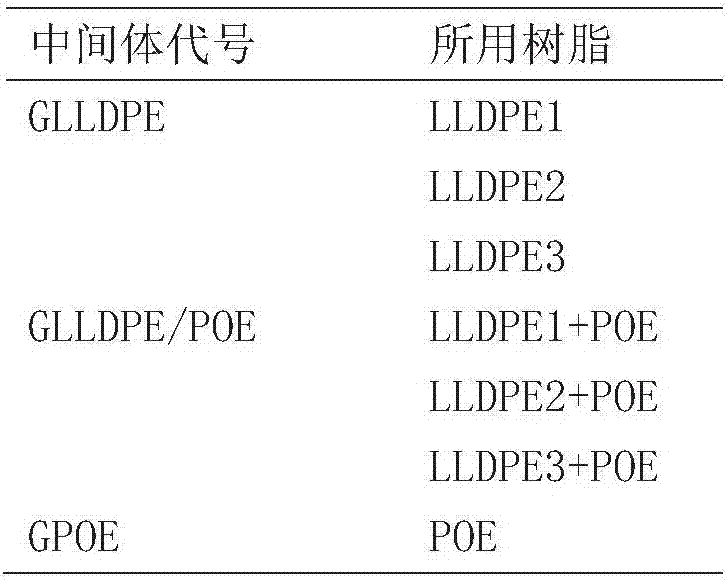

[0031] The raw materials and intermediates used in the present invention are as follows.

[0032] Table 1 lists the raw materials used in the examples of the present invention. According to the basic type of material composition, it can be classified into LLDPE1, LLDPE2, LLDPE3, POE, HDPE, LDPE, PP and PS.

[0033] In Table 1, the materials under the same category only have different manufacturers and models, and their various parameters are basically similar. There is no need to distinguish them when they are used as general-purpose adhesives. In the following examples, if there is no special description, The raw materials used are the first item in each category as the experimental material (for example, the LLDPE1 in the embodiment, unless otherwise specified, refers to the Elite 5220G manufactured by DOW). In addition, its replacement with other products under the same category, or a combination of one or more of them, any combination thereof will not affect the final per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com