Apparatus and method for metal coating of workpieces

A technology of metal coating and equipment, which is applied in the direction of metal material coating process, coating, liquid spraying device, etc., and can solve problems such as defective coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

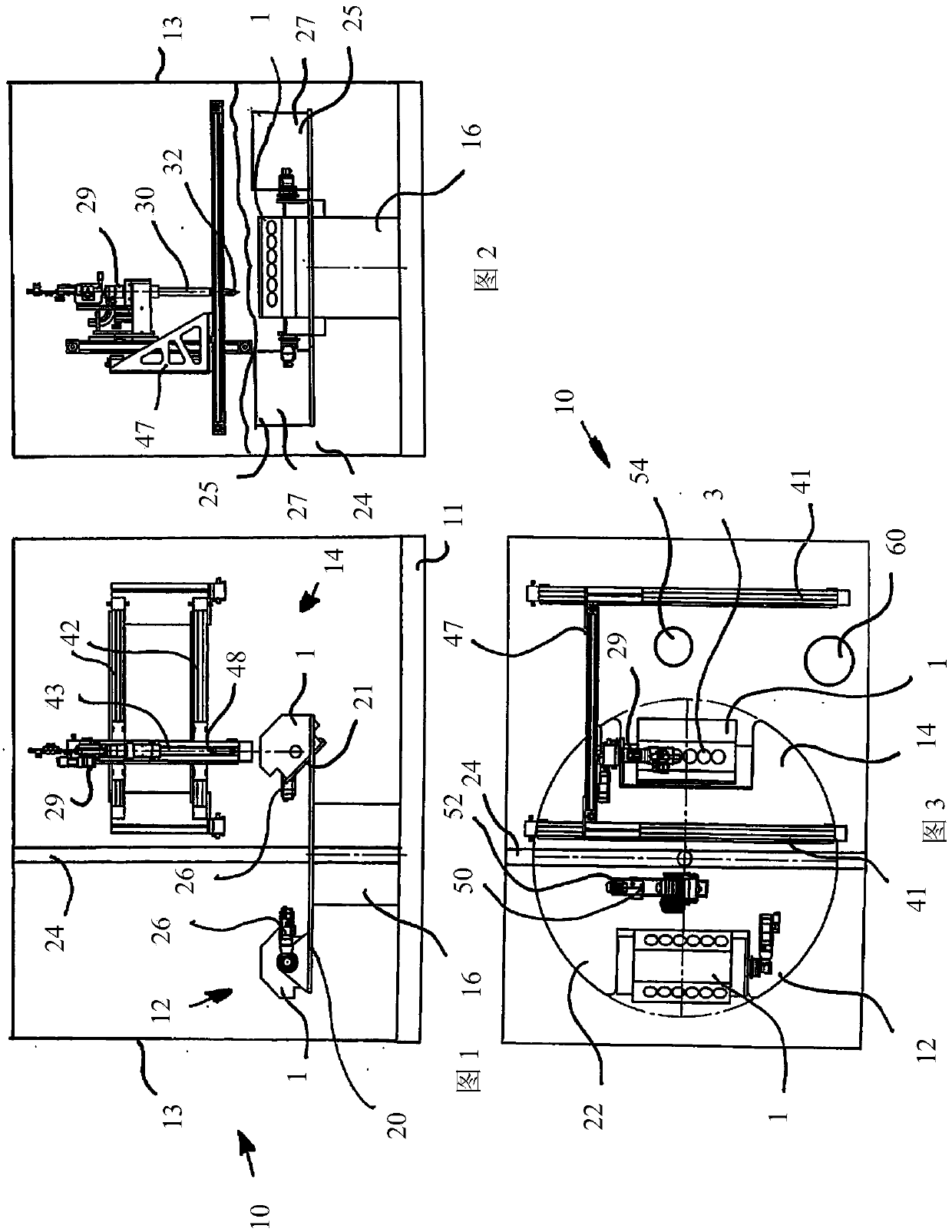

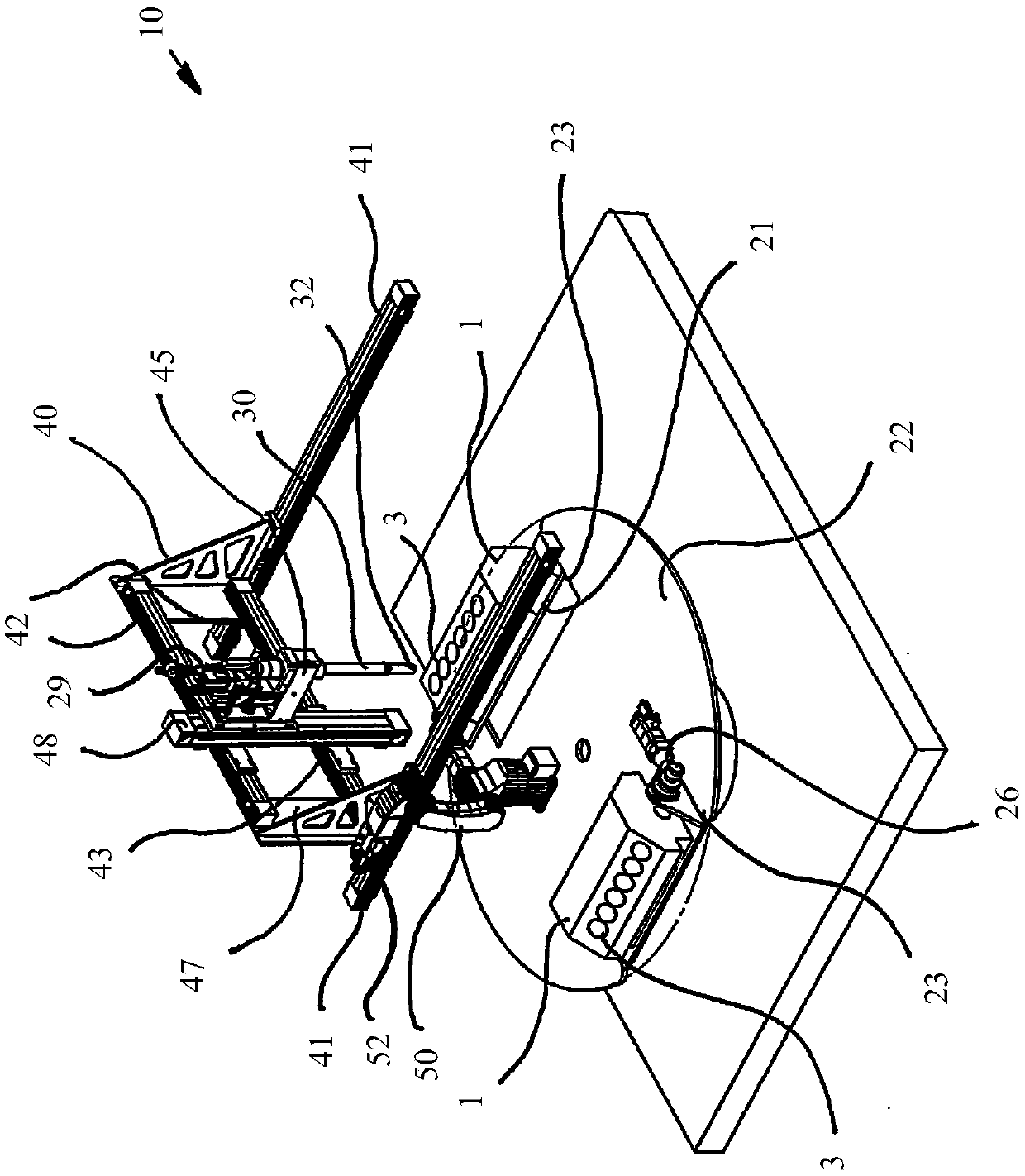

[0032] Figure 1 to Figure 4 A device 10 according to the invention for the metallization of holes 3 in a workpiece 1 is shown. In the embodiment shown, the workpiece 1 is an engine block with 12 holes 3, which are cylinder bores, arranged in the workpiece 1 in two rows of 6 in a V-shaped arrangement.

[0033] The device 10 comprises a machine base 11 on which a housing 13 is arranged. A box-shaped housing 13 surrounds the loading station 12 and the processing station 14 with the coating device 29 .

[0034] On the machine base 11 is arranged a base frame 16 of a conveyor 20 for picking up workpieces 1 , which in the embodiment shown is designed as a rotary table 22 . A horizontal rotary table 22 driven in rotation about a vertical axis of rotation comprises two workpiece holders 23 opposite each other, each provided with a plate-like platform assembly 21 each carrying a workpiece 1 . Via the rotation unit 26, the platform assembly 21 with the workpiece 1 can be rotated cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com