Method and apparatus for drawing a mass of melt-spun fiber slivers

A fiber and sliver technology, applied in the direction of stretch spinning, melt spinning, and complete sets of equipment for the production of artificial threads, etc., can solve the problems of insufficient shaping of the thin neck point, winding, and shifting of the thin neck point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

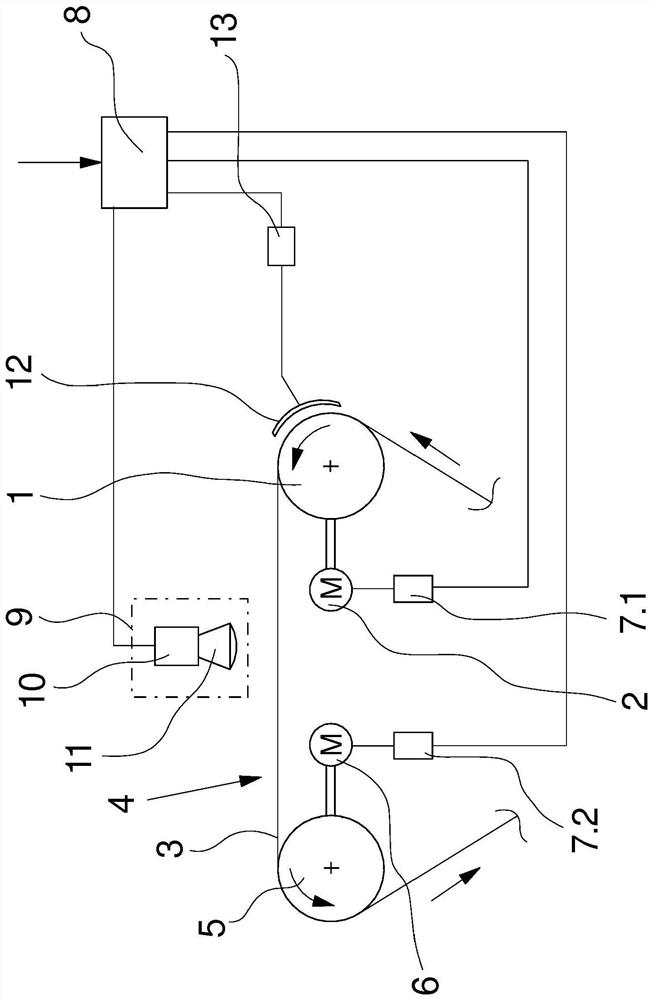

[0040] figure 1 A first embodiment of an apparatus for drawing a mass of melt-spun fiber slivers of tow is schematically shown in . The exemplary embodiment has here only the essential parts of the device required to explain the invention. To this end, a first stretching roller 1 is shown, which is connected to a roller drive 2 . The roll drive 2 is controlled by the drive controller 7.1 in such a way that the stretching roll 1 can be driven with a selectable surface speed / circumferential speed.

[0041] The second stretching roll 5 is assigned to the first stretching roll 1 and is spaced therefrom. A drawing zone 4 is defined between the drawing rolls 1 and 5 in which the tow 3 is drawn. The stretching rollers 5 are driven by a roller drive 6, which is connected to a drive controller 7.2. The drive controller 7 . 2 is connected to the control device 8 , which is likewise connected to the drive controller 7 . 1 of the roller drive 2 of the first stretching roller 1 . A di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com